The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is a plastic processing process to form a specific section profile.

Our roll forming equipment consists of decolier machine, feeding table, guiding equipment, roll forming system, post-cutting system (electric or hydraulic), controlling system and hydraulic station. Wide variety of cold-formed steel, from the sub-section shape, with open, semi-closed and closed, the main products of roll forming machine are cold-formed channel steel, angle steel, Z section steel, cold-formed corrugated steel, pipe, square tube, rectangular tube, welded tube-shaped, rolling shutter doors and so on. Steel cross-section shape can be designed: size, accuracy, and length can flexibly be adjusted according to need, all supplied by length or double length, improve maternal utilization. Production processes can also be matched with the punch, so as to meet different requirements.

As important structural parts, cold-formed steel products have been widely used in many fields such as construction, automobile manufacturing, shipbuilding, electronics industry and machinery manufacturing.

Wuxi Shenchong Forging Machine Co.,Ltd is a professional forming machine manufacturer and exporter of all kinds of standard and nonstandard roll forming machinery. We offer various sheet metal and coil metal roll forming machines such as shelf and roll forming machines, downspout roll forming machines, double layer roll forming machines with the reliable process, high productivity, high reliability.

We can provide automatic production lines such as uncoiling, leveling, feeding, punching, roll bending, welding, cutting, etc., which are used for shelf columns, joists, highway guardrails, automobile bumpers/U-beams, steel structures Production of C/Z-shaped steel, anode plate of electrostatic pre-cipitator, cable tray and other special profiles; provide uncoiling, precision leveling, feeding, punching, and forming production lines for thin-walled cold-formed steel series—such as shelf shelves, various Various cabinet panels, building composite panels and other processing.

Intelligent Manufacturing Redefine Your Future!

Also why not check our Press Brakes and Plate Shearing Machine for bending and cutting work.

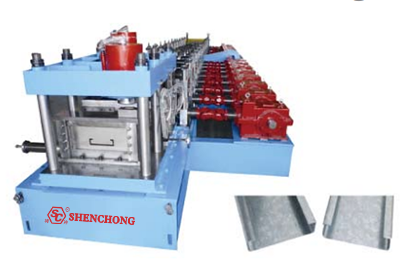

Material thickness: 0.4-0.8mm

Forming speed:15m/min-30m/min-45m/min

Roll station: 18 stations(depend on the profile)

Main power: 5.5KW-7.5KW-11KW

Hydraulic power: 4KW-5.5KW-7.5KW

Control system: PLC Panasonic

Drive: By chain

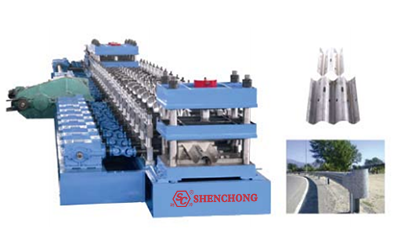

Material thickness: 1.5-3.0mm

Forming speed: 12-15m/min

Roll station: 14 stations(depend on the profile)

Main power: 15KW

Hydraulic power: 5.5KW

Control system: PLC Panasonic

Drive: By chain or gearbox

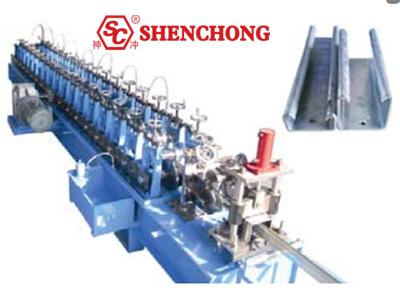

Material thickness: 2.0-3.0mm

Forming speed: 12-15m/min

Roll station: 15 stations(depend on the profile)

Main motor: 37KW

Hydraulic power: 7.5KW

Control system: PLC Panasonic

Drive: By chain or gearbox

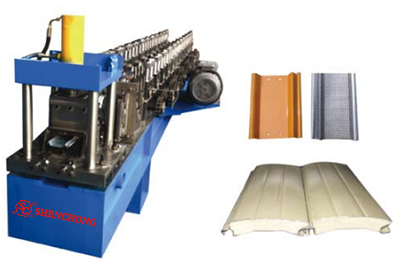

Material thickness: 2.0-3.0mm

Forming speed: 12-15m/min

Roll station: 17 stations(depend on the profile)

Main motor: 15KW

Hydraulic power: 7.5KW

Control system: PLC Panasonic

Drive: By gear

Material thickness: 1.0-2.0mm

Forming speed: 12-15m/min

Roll station: 17 stations(depend on the profile)

Main motor: 11KW

Hydraulic power: 4KW

Control system: PLC Panasonic

Drive: By chain

Material thickness: 0.7-1.2mm

Forming speed: 12-15m/min

Roll station: 14 stations

Main motor: 4KW

Hydraulic power: 3KW

Control system: PLC Panasonic

Drive: By chain

Q: How to get an accurate roll forming machine price from SHENCHONG?

A: Every customer can get metal roll forming machine line price from us. Please contact with us and provide us your forming reqirements .

Q: Can you do OEM service for roll forming machine lines?

A: Yes, we can. Your design is accepted, your own logo can be used on the roll forming machine.

Q: What is the shipping cost from China to your country?

A: We can send sheet metal roll forming machine to your port or door address by sea or rail. please kindly tell us your nearest port. We have reliable shipping agent to insure the safe convenient and time delivery.

Q: Do you accept LC payment?

A: Yes, normally our payment is 30%+70% T/T, LC payment is also acceptable. Our roll forming machine price is affordable, contact with us today!