The sheet metal punching hole arrangement design needs to comprehensively consider factors such as material utilization, hole shape arrangement, hole spacing, punching sequence, stress distribution and die life.

By optimizing the arrangement and arranging the processing sequence reasonably, material waste can be effectively reduced, sheet deformation and die damage can be avoided, thereby improving processing efficiency and product quality. The following are the main principles and techniques for designing sheet metal punching hole arrangement.

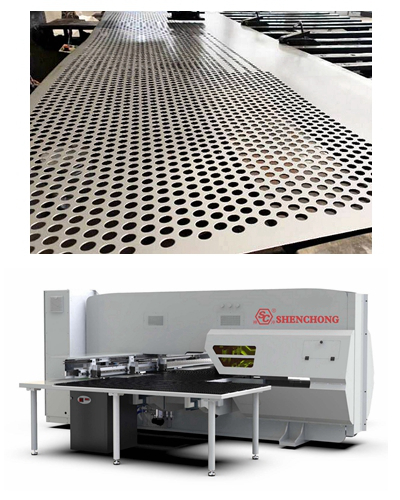

In order to save materials, it is usually considered to arrange the holes as compactly as possible to reduce material waste.

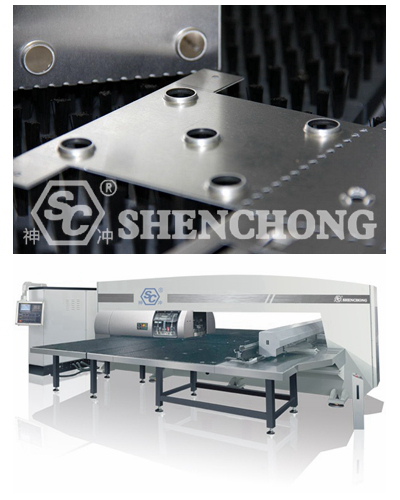

The holes are arranged in a straight line, which is suitable for rectangular or regular-shaped plates. The process is simple and conducive to mold design and automated stamping.

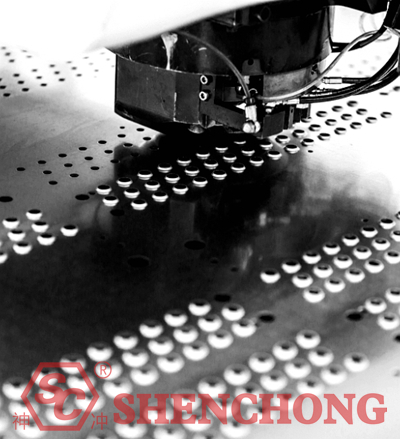

The holes are arranged in a "plum blossom" shape, which is usually used for the arrangement of circular or elliptical holes. It can improve material utilization and reduce waste. Especially for mass production, staggered arrangement can significantly reduce material waste.

The spacing between holes (or the distance between holes and the edge of the plate) is crucial to the smooth progress of the stamping process. If the spacing design is unreasonable, it may cause material deformation, tearing of the hole edge or premature wear of the mold.

Generally, the minimum value of the hole spacing should not be less than 2 times the material thickness, that is:

D min=2×t, where D min is the hole spacing and t is the material thickness.

For thicker or harder materials, the spacing can be appropriately increased to avoid plastic deformation of the material during stamping.

The distance from the hole to the edge of the plate should ensure that the material does not tear during the punching machine process, and usually the distance should not be less than 2 times the material thickness. For softer materials or larger holes, the edge distance should be appropriately increased to avoid edge cracking.

Click here to know other hole cutting:

Problems And Solutions For Laser Cutting Round Holes

The hole layout design should be as uniform and symmetrical as possible, so that the force on the plate can be balanced during punching, avoiding problems such as material warping and deformation during punching. At the same time, uniform layout can also reduce the eccentric wear of the mold and extend the life of the mold.

Make sure that the spacing between each hole and the surrounding holes is equal to avoid the concentrated force in the dense area of the holes causing material deformation.

If the sheet metal punching holes are arranged in a certain pattern or multiple holes need to be fixed in position, try to arrange them symmetrically to reduce stress concentration during processing.

For square holes, special-shaped holes and other holes with sharp corners, the corners should be designed to be rounded to reduce stress concentration, extend the life of the mold, and avoid cracking of the hole edge during punching.

If multiple holes need to be processed, try to process the complex or large holes in the later stage of the process to reduce the impact of initial stress on the material.

If there are multiple holes on the same sheet, especially large and small holes, it is recommended to punch the large holes first and then the small holes to reduce stress concentration and deformation.

For complex arrangements, multi-station molds or continuous molds can be used to gradually complete the processing of different hole shapes to ensure processing accuracy and flatness of the sheet.

If the shape or size of the punched holes is complex and the distance between the holes is too close, it is easy to cause edge tearing or deformation of the sheet during the punching process.

Therefore, when designing the arrangement, you should consider increasing the spacing between the holes, or reduce stress by the following methods:

For square or special-shaped holes, you can increase the fillet of the corners to reduce stress concentration and reduce the possibility of deformation or cracking.

When the hole shape is complex or the hole density is high, you can use multi-stage punching (first punch out the small hole, then gradually increase the hole diameter) to reduce stress concentration and ensure the quality of the hole.

During the stamping process, the plate is prone to bending or twisting under stress. In order to reduce this deformation, the layout design should be:

Especially on longer plates, punching should be done step by step to avoid punching all holes at once to prevent the plate from warping.

By reasonably designing the support position of the mold, the suspended part of the plate during stamping can be reduced to prevent bending and deformation.

Materials with high hardness and thickness require more spacing and stronger punching force, so a suitable layout needs to be designed to avoid excessive wear of the mold or cracking of the material.

For softer or more plastic materials, the hole spacing and edge distance can be appropriately reduced, but it is still necessary to ensure that the material does not deform excessively.

When multiple holes are required to form a linear or grid shape, a hole chain or mesh hole arrangement can be designed to avoid excessive material cutting while maintaining strength.

Especially for thin plates or plates that need to bear large loads, reinforcing ribs can be reserved during design to reduce the density of holes to enhance the structural strength of the plate.

Design the position and number of waste discharge holes to ensure that waste can be discharged smoothly to avoid clogging the mold or affecting the punching accuracy.

Through reasonable sheet metal punching hole arrangement, waste can be minimized and material utilization can be improved, especially in production scenarios where cost control is more important.

The sheet metal punching hole layout design needs to be coordinated with the mold structure, especially for the stamping process of mass production, the shape of the mold and the layout of the punch must be consistent with the plate hole design.

The following should be considered when designing the mold:

- Mold layout: The design of the mold should match the layout diagram to ensure that the mold maintains a uniform distribution when bearing the punching force, reducing local wear and eccentric wear.

- Multi-station mold: Suitable for complex workpieces that require multiple holes, and can complete punching of different shapes or sizes in a set of molds.

- Continuous mold: Suitable for mass production, the material moves gradually in the mold to complete the punching process in sequence.

The layout design of metal sheet punching hole should comprehensively consider factors such as material utilization, hole spacing, plate strength, mold life and processing accuracy. Through reasonable layout and design, the utilization rate of materials can be improved, mold wear can be reduced, and deformation and tearing of the plate can be avoided, thereby achieving efficient and high-quality production.

Click here to know more about: