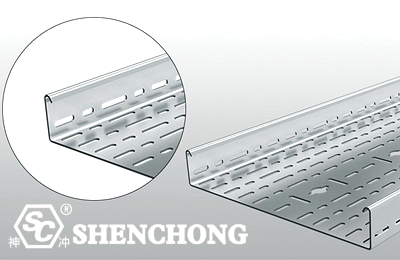

The sheet metal cable tray automated production line is a highly automatic equipment used to manufacture cable trays. Cable trays are structural parts used to support and protect wires and cables, and are widely used in construction, electricity, communications and other industries. Automatic production lines can greatly improve production efficiency, reduce labor costs, and improve product consistency and quality.

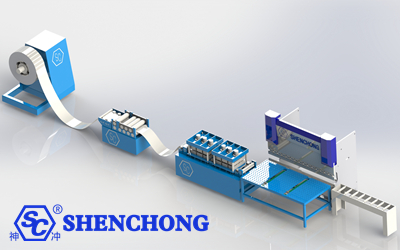

The composition of sheet metal cable tray automatic production lines usually includes multiple automated equipment, each of which completes different processing steps to form a complete production process. The following is a detailed introduction to common components:

- Function: Used to unfold large rolls of metal sheets and feed them into the production line.

- Features: Equipped with automatic feeding and tensioning devices to ensure that the steel strip maintains consistent tension during the unfolding process.

- Function: Level the steel strip, remove the bending and unevenness of the sheet, and ensure that it has sufficient flatness when entering the subsequent process.

- Features: The pressure can be adjusted and is suitable for steel of different thicknesses.

- Function: Accurately feed the leveled steel strip into the punching or shearing process.

- Features: The servo control system ensures the accuracy and stability of feeding, and can accurately feed according to the set length.

- Function: Punch holes on the steel strip to form ventilation holes, installation holes, etc. of the cable tray.

- Features: The shape and position of the holes can be flexibly adjusted according to the design requirements of the cable tray, and mold replacement is supported.

- Function: Cut the steel strip according to the set length to form the basic skeleton of the cable tray.

- Features: It adopts hydraulic or mechanical transmission, with high shearing accuracy and smooth cuts.

- Function: Bend the sheared steel plate into the shape of the cable tray, usually a trough, tray or ladder structure.

- Features: It can be automatically bent in multiple stations and adjusted flexibly to meet the production needs of cable trays of different specifications.

Cable Tray Automatic Bending CNC Press Brake To Egypt

- Function: Automatically weld the cable tray components that need to be welded, such as reinforcing ribs or other connecting parts.

- Features: Automated welding equipment ensures uniform welds and stable quality, reducing the defects of manual welding.

- Function: Surface treatment of the formed cable tray, usually anti-corrosion spraying.

- Features: Anti-corrosion paint or hot-dip galvanizing can be automatically sprayed to ensure the anti-corrosion performance of the tray during use.

- Function: Cool and dry the sprayed tray for subsequent processing and stacking.

- Features: The drying furnace can quickly solidify the coating to ensure the durability and adhesion of the coating.

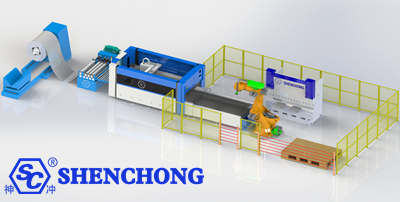

- Function: Automatically stack the completed cable trays neatly to facilitate subsequent packaging and transportation.

- Features: Reduce manual operation, improve work efficiency, smooth stacking process, and reduce product damage.

- Function: The core control part of the entire production line, controlling the entire production process through PLC or DCS system.

- Features: Easy to operate, parameter setting and monitoring can be performed through touch screen or computer to achieve automatic and intelligent management.

- Function: Automatically inspect the produced cable trays to ensure the qualified rate of size, hole position, welding quality and coating.

- Features: High-precision sensors and inspection equipment can alarm and remove unqualified products in real time.

These devices work together to form an efficient and automated production process to ensure high-quality and mass production of sheet metal cable trays. Each link of the production line can be customized and optimized according to needs to adapt to the production of cable trays of different types and specifications.

The sheet metal cable tray automated production line has several significant features that can significantly improve production efficiency and product quality while reducing costs. Here are its main features:

- Features: Automatic production lines can achieve large-scale continuous production, and the production speed is much higher than traditional manual or semi-automatic operations. Automated equipment at every stage works together to reduce interruptions and ensure efficient operations.

- Advantages: Greatly increase production, shorten delivery cycle, suitable for bridge needs in large-scale engineering projects.

- Features: Automatic control through PLC (programmable logic controller) or DCS (distributed control system), which can accurately adjust the parameters of each step in the production process, such as feeding length, punching position, bending angle, etc.

- Advantages: Reduce human errors, ensure consistent specifications of each product, and improve the accuracy and consistency of finished products.

- Features: The specifications, shape and hole layout of the bridge can be adjusted according to customer needs, and the production of multiple types of bridges can be supported.

- Advantages: It can flexibly adapt to the customized needs of different projects. Whether it is mass production or small batch customization, the equipment can quickly switch settings.

- Features: The operation of the automatic production line requires only a small number of personnel for equipment monitoring and management, reducing reliance on manual operations.

- Advantages: While reducing labor costs, it also reduces errors and safety hazards caused by human operations, further improving the stability of production.

- Features: Due to the automation and standardization of the production process, the dimensional accuracy, punching position, bending angle and surface treatment quality of the product can be highly consistent, avoiding errors and defective products in traditional manual processing.

- Advantages: The finished bridge has better structural strength, durability and consistency, and meets strict engineering quality requirements.

- Features: The production line has a high degree of automation, covering a series of processes from uncoiling, leveling, punching, shearing, bending, spraying to palletizing, etc., reducing the need for manual intervention.

- Advantages: Greatly shortens production time and improves overall production efficiency, especially suitable for mass production.

- Features: Modern automated production lines are equipped with energy-saving technologies, such as high-efficiency motors, intelligent energy management systems, etc., which can reduce energy consumption while ensuring efficient operation of equipment.

- Advantages: Reduce energy consumption, reduce production costs, comply with environmental protection requirements, and reduce environmental impact.

- Features: The automated production line is equipped with multiple safety protection mechanisms, including overload protection, emergency shutdown, automatic alarm and other functions to ensure that the equipment can automatically stop running under abnormal circumstances and ensure the safety of operators.

- Advantages: Reduce the risk of work-related injuries and improve factory safety management.

- Features: Automated equipment can accurately control punching and shearing processes, avoiding material waste and unnecessary cutting.

- Advantages: Improve material utilization, reduce production costs, and reduce waste generation.

- Features: The production line can integrate a data management system to monitor production data in real time, such as output, equipment status, energy consumption, etc.

- Advantages: The production process is transparent. Managers can optimize production efficiency through data analysis and track the production process of each batch of products to facilitate quality traceability and improvement.

- Features: Mold replacement is quick and convenient, supports the production of multiple specifications and types of cable trays, and does not require long shutdown adjustments.

- Advantages: Improve the flexibility and work efficiency of the production line, reduce line change time, and is suitable for processing diversified orders.

Through the application of intelligence and automation technology, the sheet metal cable tray automated production line not only improves production efficiency and product quality, but also reduces operating costs and manpower requirements. It is a key tool for modern manufacturing enterprises to improve their competitiveness.

Click here to know more about cable tray production line:

High Speed Automatic Cable Tray Production Line

The scope of application of sheet metal cable tray automated production line is wide, mainly covering the following industries and application scenarios:

Application: In various construction projects, such as residential buildings, office buildings, industrial plants, etc., cable trays are used to support and protect cables to ensure the safe operation of power and communication systems.

Features: The cable tray can adapt to different building structures and design requirements, providing flexible cable wiring solutions.

Application: In power stations, substations and distribution rooms, cable trays are used to organize and protect power cables to ensure reliable transmission and distribution of electricity.

Features: Able to withstand large cable loads and environmental factors, ensuring the safety and stability of the power system.

Application: In communication base stations, data centers, computer rooms and other places, cable trays are used to manage fiber optic cables and network cables to provide efficient network connections.

Features: Meet the needs of high-speed data transmission while ensuring the safety and orderly arrangement of cables.

Application: In automated production lines and industrial equipment, cable trays are used to manage power and control cables to ensure the normal operation of equipment.

Features: Adapt to various industrial environments and protect cables from mechanical damage and environmental impact.

Application: In transportation infrastructure such as subways, railway stations, and highways, cable trays are used to support and protect traffic signals, monitoring, and communication cables.

Features: Provide reliable cable wiring solutions to support the safe operation of transportation systems.

Application: In places such as oil refineries and chemical plants, cable trays are used to manage cables in hazardous environments to ensure safety and protection.

Features: Anti-corrosion and high temperature resistance, suitable for use in harsh environments, ensuring the safety and reliability of cables.

Application: In hospitals and medical equipment, cable trays are used to support and protect medical cables to ensure the normal operation of medical equipment.

Features: Strict safety standards must be met to ensure power supply in critical situations.

Application: In environmental protection facilities such as sewage treatment plants and waste incineration plants, cable trays are used to manage cables to support the safe and efficient operation of equipment.

Features: Able to withstand special environmental influences such as humidity and corrosion to protect cable safety.

Application: In data centers, cable trays are used to arrange network cables and power cables in an orderly manner to ensure the stability of data transmission and power supply.

Features: Provide efficient space utilization and cable management, and support high-speed data flow.

Application: In ships and offshore platforms, cable trays are used to manage cables to ensure safe operation in marine environments.

Features: Resistant to salt spray and corrosion, and adaptable to complex marine working conditions.

The First Cable Tray Automatic Production Flexible Line in China by Wuxi Shenchong

The sheet metal cable tray automation production line can meet the needs of a variety of industries, and provide flexible and reliable cable management solutions by producing cable trays of different specifications and types. This makes it play an important role in modern industrial and infrastructure construction.

As an indispensable infrastructure in modern electrical engineering, the improvement of sheet metal cable tray production efficiency and quality is directly related to the overall effectiveness and safety of engineering projects. With the rapid development of automation technology, the sheet metal cable tray automation production line has gradually become the mainstream production method in the industry. This article will discuss in detail the main technologies used in the sheet metal cable tray automated production line from multiple aspects.

With the advancement of Industry 4.0, the sheet metal cable tray automated production line will be more intelligent and information-based. Through the application of automation technology, the production efficiency of the cable tray manufacturing industry has been comprehensively improved. The production labor cost has been reduced, the mechanized productivity has been improved, and many deficiencies in the original mechanical production have been improved.

Automated production technology plays a good role in promoting the overall development of the cable tray manufacturing industry. Wuxi Shenchong fully utilizes sheet metal automation technology to design and produce flexible production lines for cable trays. This technology has been fully applied in the bending, cutting and forming of the cable tray, greatly improving the production efficiency of the product.