In recent years, with the continuous acceleration of industrial development towards high-end and intelligent directions, the advantages of fiber lasers have gradually become prominent, and the market penetration rate has also been continuously increasing. At present, the market share of fiber lasers in the industrial field has exceeded 50%, making them the absolute king in this field.

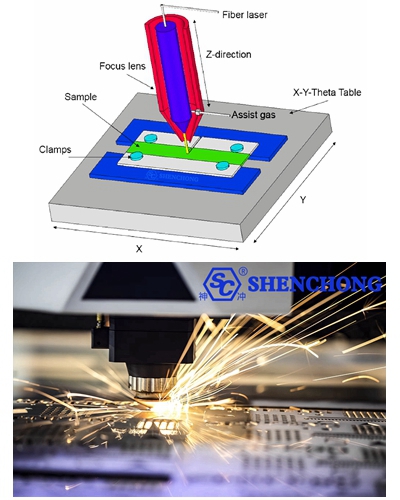

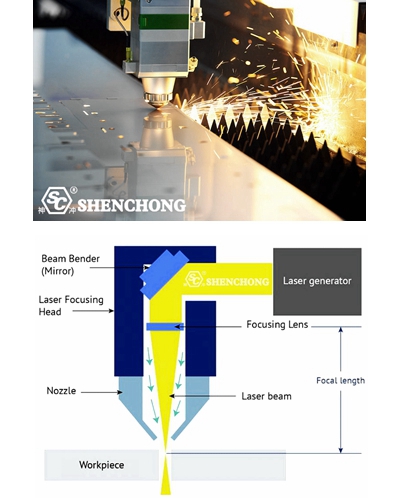

Fiber laser is an ideal type of laser that achieves small volume, high efficiency, high reliability, high beam quality, and high output by amplifying specific wavelengths of light inside the fiber.

Fiber laser refers to a laser that uses rare earth element doped glass fiber as the gain medium. Fiber laser can be developed based on fiber amplifier: under the action of pump light, high power density is easily formed inside the fiber, causing a "particle number inversion" of the laser working material's laser energy level. When a positive feedback loop (forming a resonant cavity) is appropriately added, laser oscillation output can be formed.

Fiber lasers have a wide range of applications, including laser fiber communication, laser space long-distance communication, industrial shipbuilding, automobile manufacturing, laser engraving, laser marking, laser cutting, printing rollers, metal and non-metal drilling/cutting/welding (copper welding, quenching, cladding, and deep welding), military and national defense security, medical equipment and equipment, large-scale infrastructure, and serving as a pump source for other lasers.

Fiber laser is a type of laser that uses fibers as the laser medium. It has the advantages of high efficiency, high power, and high-quality beam, and is widely used in fields such as communication, medical treatment, and material processing. This article will provide a detailed introduction to the origin, development, and application of fiber lasers.

The origin of fiber lasers can be traced back to the early 1960s, when researchers at Bell Laboratories in the United States first proposed the idea of combining laser amplifiers with fibers. However, due to the immaturity of fiber preparation technology at that time, the practical application of fiber lasers was greatly limited.

It was not until the early 1970s that fiber lasers gradually became a research hotspot with the breakthroughs in fiber optic technology and the development of laser technology. In 1970, Peter C. from Bell Laboratories in the United States Schultz et al. first realized the working principle of fiber laser amplifiers, marking the birth of fiber lasers.

The development of fiber lasers cannot be separated from the progress of fiber technology. In the mid-1970s, researchers began using single-mode fibers as the laser medium for fiber lasers to improve beam quality and power output. Subsequently, the preparation process of optical fiber materials continued to improve, and the loss of optical fibers gradually decreased, resulting in a significant improvement in the performance of fiber lasers.

With the technological breakthrough of fiber lasers, their application fields have also been widely expanded. The application of fiber lasers in the field of communication is particularly important. In 1983, Kumar N. Patel from Bell Laboratories in the United States first applied fiber lasers to fiber communication systems, achieving long-distance and high-speed fiber transmission, opening the door to the era of optical communication.

In addition to the communication field, fiber lasers also play an important role in medical and material processing fields. In terms of medicine, fiber lasers can be used for laser surgery, laser treatment, etc., with the characteristics of small trauma and fast recovery. In terms of material processing, fiber lasers can be used for processes such as cutting, welding, and drilling, with the advantages of high precision and efficiency.

With the continuous progress of technology, the performance and application fields of fiber lasers will continue to expand. At present, researchers are working to improve the power output and beam quality of fiber lasers to meet higher demand application scenarios. Meanwhile, fiber lasers also have broad development prospects in fields such as LiDAR and fiber optic sensing.

Fiber laser, as an important laser device, has gone through a process of origin and development, and plays an important role in fields such as communication, medicine, and material processing. With the advancement of technology, the performance and application of fiber lasers will continue to improve, bringing more convenience and possibilities to people's lives

Laser equipment is essential in the intelligent equipment manufacturing process and is also one of the key roles for China's manufacturing to move towards high-end and intelligent manufacturing.

Compared to traditional processing equipment, laser equipment has stronger processing capabilities, higher accuracy, and significantly improved processing efficiency.

Fiber lasers have had a significant and positive impact on the traditional laser industry due to their absolute ideal beam quality, ultra-high conversion efficiency, complete maintenance free, high stability, and small size.

The development of high-power, high-quality, efficient, and compact high-energy laser systems using fiber lasers is a long-term exploration and research goal for countries around the world.

As a hot topic in the field of high-power laser light source research in recent years, fiber lasers have advantages such as simple structure, good heat dissipation effect, high conversion efficiency, low threshold, long service life, and simple system maintenance compared to gas or conventional solid lasers.

Especially in recent years, with the emergence of double clad fibers, multimode pumping has become possible, providing a solution for improving the output power of fiber lasers and achieving high-power output of rare earth element doped fiber lasers.

However, due to the nonlinear effects generated by a single fiber laser under high power conditions and the limitation of the threshold power that the fiber itself can withstand, a single fiber laser cannot achieve ultra-high power. Therefore, coherent synthesis of fiber lasers has become an important research direction.

There are two main ways to achieve coherent synthesis of fiber lasers: main oscillation power amplification and self-organizing fiber laser array.

Compared to the main oscillation power amplification method, self-organizing fiber laser arrays have the characteristics of compact structure, simple phase control, and high synthesis efficiency, making them a hot topic in recent theoretical research.

At present, theoretical research on self-organizing fiber laser arrays mainly focuses on two aspects.

On the one hand, it is the study of the spectral response parameters of fiber laser arrays. Because the spectral response parameter is one of the key parameters in self-organizing fiber coherent synthesis technology, it determines the frequency band of the array output signal.

On the other hand, it is the study of the dynamic characteristics of fiber laser arrays. As a complex system, studying the dynamic characteristics of fiber laser arrays is beneficial for understanding the operating mechanism of the entire system, improving the overall system, and thus enhancing the beam quality of the output signal.

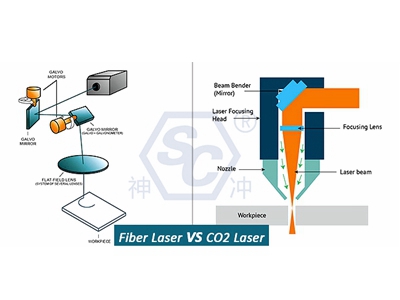

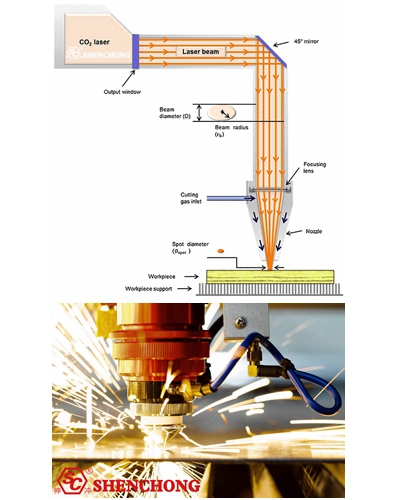

Currently, common lasers in the market include CO2 lasers (gas lasers), YAG lasers (solid state), fiber lasers, semiconductor lasers, and so on. Due to their different working characteristics, there are also significant differences in their respective application fields.

For example, CO2 lasers are more suitable for natural material processing, such as materials with relatively weak hardness such as leather and plastic.

In addition, CO2 lasers are also widely used in the medical field. However, due to its large volume, complex structure, and difficult maintenance, its applications in some fields are gradually being replaced by fiber lasers with better comprehensive characteristics.

Fiber laser is known as the third-generation laser and has a wide range of applications. Including laser fiber optic communication, laser space long-distance communication, aerospace, industrial shipbuilding, automobile manufacturing, laser engraving, laser marking, laser cutting machine, printing rollers, metal non-metal drilling/cutting/welding (copper welding, quenching, cladding, and deep welding), military and national defense security, medical equipment and instruments, large-scale infrastructure, as well as serving as a pump source for other lasers, and so on.

Fiber laser can be accepted in such a wide range of fields mainly due to its advantages in many aspects, such as compact structure, high photoelectric conversion efficiency, strong reliability, good beam quality, and so on. With the continuous growth of related demand, the competitive advantage of fiber lasers in the high-power market is becoming increasingly prominent.

Click here to know more about: Fiber Laser Cutting Machine VS CO₂ Laser Cutting Machine | Which Is Better?

Laser technology, which originated in the 1960s, is one of the four new inventions in the 20th century as famous as atomic energy, semiconductor and computer. The discovery and practical application of scientific theories require a long process.

In the last century, Einstein was the first to propose the photon hypothesis and explain the theory of photoelectric effects. Later, he also proposed the stimulated radiation theory, laying the theoretical foundation for laser technology. Unfortunately, Einstein had passed away for 5 years by the time Theodore Mayman invented the world's first ruby laser on July 8, 1960.

Fiber laser is a laser that uses fiber as the pumping medium, and the world's first glass laser was a fiber laser. However, few people know that just one year after Theodore Mayman successfully manufactured the ruby laser, Changchun Institute of Optics and Precision Machinery, Chinese Academy of Sciences subsequently produced the first ruby laser in China, laying the foundation for the rise of China's laser industry.

Due to the strong demand for laser equipment in the Chinese manufacturing market, foreign manufacturers represented by COHERENT, IPG, and SPI are actively entering the Chinese market and competing with Chinese manufacturers in the vast domestic manufacturing market.

The United States was the first country to use fiber lasers in its manufacturing industry. Among the top five major laser manufacturers in the world, Coherent, IPG, and II-VI are from the United States. IPG has always been a leader in global fiber lasers. Thanks to the rapid growth of the global fiber laser processing market, IPG has achieved rapid growth in market performance in recent years.