Choose a laser cleaning machine is a complex task that requires comprehensive consideration of many factors to ensure that the selected equipment can meet the specific application requirements while having good performance and cost-effectiveness.

The following is a detailed analysis from multiple aspects such as laser power, wavelength, cooling system, operating interface, portability, brand and after-sales service, cost, safety, etc.

The power of a laser cleaning machine is an important parameter that determines its cleaning ability. Different application scenarios have different requirements for laser power:

Low-power laser cleaning machine is suitable for cleaning delicate surfaces, such as cultural relic restoration, microelectronic component cleaning, etc. The power of this type of cleaning machine is usually between tens of watts and hundreds of watts, which can effectively remove fine dirt without damaging the substrate.

know more about: What Is Laser Cleaning? Working principle, features and applications

High-power laser cleaning machine is suitable for cleaning large areas and stubborn dirt, such as rust removal of ship hulls, cleaning of large equipment, etc. The power of this type of cleaning machine can reach thousands of watts, with strong cleaning capabilities, and can complete tasks quickly and efficiently.

Laser wavelength affects the interaction between laser and material, thus affecting the cleaning effect. Commonly used laser wavelengths include 1064nm (near infrared), 532nm (green light), etc.:

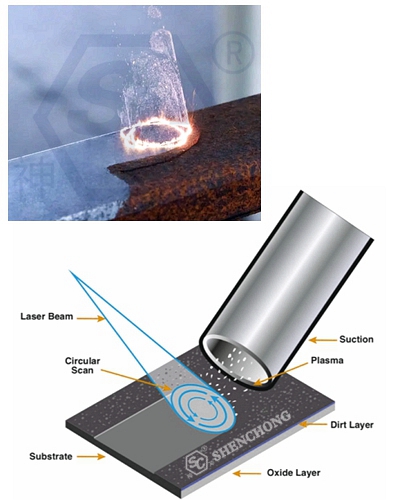

1064nm wavelength is suitable for cleaning most metal materials, with high absorption rate and cleaning efficiency. Widely used in industrial cleaning, rust removal, oxide layer removal and other fields.

532nm wavelength is suitable for cleaning non-metallic materials, such as plastics, glass, etc. Due to its shorter wavelength, it can better control the heat-affected zone and avoid damage to the substrate.

The laser cleaning machine will generate a lot of heat during operation, and a good cooling system can ensure the stable operation of the equipment. The cooling system is mainly divided into air cooling and water cooling:

The air cooling system is suitable for low-power laser cleaning machines, with simple structure and easy maintenance. However, for high-power equipment, the cooling effect of the air cooling system is limited.

The water cooling system is suitable for high-power laser cleaning machines, with higher cooling efficiency, can effectively control the working temperature of the laser, and ensure long-term stable operation of the equipment.

Modern laser cleaning machines are usually equipped with a user-friendly operation interface and automation functions, which not only improves the ease of use of the equipment, but also significantly improves work efficiency:

Choosing equipment with a friendly operation interface can facilitate users to perform operations such as parameter setting and mode selection. Touch screen interface and intuitive menu design are ideal choices.

Laser cleaning machines with a high degree of automation can achieve automatic cleaning through programming, reduce manual intervention, and improve work efficiency. Automated equipment is especially important for batch cleaning tasks.

Depending on the usage scenario, the portability of the laser cleaning machine is also an important consideration:

Portable laser cleaning machine is suitable for scenarios that require frequent movement, such as outdoor cleaning, mobile maintenance, etc. Portable equipment is small in size and light in weight, easy to carry and operate.

Fixed laser cleaning machine is suitable for industrial applications in fixed locations, such as cleaning tasks on production lines. Fixed equipment usually has high power and is suitable for high-intensity cleaning work.

Choosing a brand with a good reputation and perfect after-sales service can ensure the quality and subsequent maintenance of the equipment:

Give priority to well-known brands in the industry. These brands usually have rich technical accumulation and high market recognition, and can provide stable and reliable products.

Understand the manufacturer's after-sales service policy, including warranty period, repair service and technical support. Choosing a manufacturer with a perfect after-sales service system can solve problems encountered during the use of the equipment in a timely manner and ensure the normal operation of the equipment.

When purchasing a laser cleaning machine, cost is also a factor that needs to be considered:

Choose the right equipment according to the budget. Although high-end equipment has better performance, budget constraints also need to be considered. Consider performance and cost comprehensively and choose equipment with high cost performance.

Operating costs include power consumption, maintenance costs, etc. Choosing equipment with high energy efficiency and low maintenance costs can save expenses in long-term use.

Laser cleaning involves high-energy lasers, which may pose certain risks to operators and the surrounding environment. Choose equipment with complete safety protection measures to ensure safe use:

Safety protection devices include laser protection covers, emergency stop buttons, etc., which can quickly stop the operation of the equipment in unexpected situations to prevent laser damage.

Manufacturers should provide detailed operating manuals and safety training to guide users to use the equipment correctly and avoid safety hazards caused by improper operation.

There are certain safety risks in the use of laser cleaning machines, and users need to pay attention to the following safety issues:

Eye protection:

The laser beam emitted by the laser cleaning machine has a high energy density, and direct or indirect contact with the eyes may cause serious eye damage, including permanent vision damage. Operators must wear professional laser protection glasses and should avoid looking directly at the laser beam.

Skin protection:

Although the laser is mainly focused on the cleaning target, the scattered laser may still cause burns to the skin. Therefore, operators should wear protective clothing to avoid exposing the skin to the laser.

Air pollution:

During the laser cleaning process, the dirt, oxide layer or coating on the surface of the material will evaporate instantly under the action of high-energy lasers, producing smoke and tiny particles. These fumes and particles may contain toxic substances, and long-term inhalation may cause harm to the respiratory tract and physical health.

Ventilation measures:

When using a laser cleaning machine, it should be carried out in a well-ventilated environment, and it is best to be equipped with industrial exhaust equipment to promptly discharge the generated smoke and harmful particles.

Operation Training:

The operation of laser cleaning machines requires certain professional knowledge, and untrained personnel should not operate the equipment. Operators should receive relevant safety training and understand the working principle, operation steps and emergency response measures of the equipment.

Equipment Maintenance:

Regularly inspect and maintain the laser cleaning machine to ensure that the various safety protection measures of the equipment (such as emergency stop button, safety lock, etc.) are intact to prevent safety accidents caused by equipment failure.

Material Burning:

Some materials may burn or explode under the high temperature of the laser, especially flammable and explosive items. Therefore, before laser cleaning, it is necessary to ensure that the cleaning object does not contain flammable and explosive materials, and the cleaning area should also be away from flammable items.

Fire Extinguishing Preparation:

Appropriate fire extinguishers should be equipped in places where laser cleaning machines are used to prevent fire accidents from occurring and can be handled quickly.

Power Safety:

Laser cleaning machines are usually high-power devices and need to be connected to high-voltage power supplies. Ensure that the power supply line of the equipment meets safety standards to avoid electric shock or fire accidents caused by circuit short circuit or overload.

Equipment Grounding:

Proper grounding is an important measure to prevent electric shock. Ensure that the grounding device of the laser cleaning machine is intact to prevent static electricity accumulation and electrical failure.

Equipment stability:

The installation of the laser cleaning machine should ensure its stability to avoid equipment collapse or displacement due to vibration or collision, which may cause safety accidents.

Operation space:

Sufficient operating space should be reserved around the equipment to prevent operators from colliding or being pinched due to small space.

In short, when operating a laser cleaning machine, you must strictly follow safety regulations and operating manuals, be equipped with appropriate protective equipment, and remain vigilant to ensure personal safety and the normal operation of the equipment.

Click here to know other laser machines:

Fiber Laser Cutting Machine For Sale

Laser Cutting Automatic Production Line

When choosing a laser cleaning machine manufacturer, you can consider the following aspects:

Understand the manufacturer's qualifications, certifications and industry experience, and ensure that it has relevant production licenses and quality management system certifications (such as ISO certification).

Check the manufacturer's history and customer reviews, and choose a manufacturer with a good reputation and credibility in the industry.

Investigate the manufacturer's R&D capabilities to understand whether it has the ability to conduct independent R&D and the strength of the technical team.

Ask the manufacturer whether its product technology has unique advantages, such as the type of laser source, power range, cooling method, etc.

Ensure that the key components used in the product (such as lasers, control systems, etc.) are from well-known suppliers, and that the product design is reasonable and the performance is stable.

You can request a trial or visit the actual equipment operation to understand the cleaning effect, ease of operation and durability of the equipment.

Understand the after-sales service system of the laser cleaning machine manufacturer, including warranty period, maintenance response time, technical support, etc.

Give priority to manufacturers that provide timely and professional after-sales service to ensure that the equipment can be well maintained and supported during use.

Price is an important consideration, but you should not simply pursue low prices. After all, you get what you pay for.

Compare the quotations of different manufacturers, while paying attention to the overall cost-effectiveness of the products, to ensure that the selected products can meet the needs in terms of technology, quality and service.

Understand the manufacturer's previous successful cases, especially application examples related to your own industry.

Investigate the manufacturer's customer base. Manufacturers selected by well-known companies or industry leaders usually have higher reliability.

If there are special cleaning needs, understand whether the manufacturer can provide customized solutions.

Investigate its ability to customize development and adjustments according to customer needs.

Through the comprehensive consideration of the above aspects, you can choose the right laser cleaning machine manufacturer. Purchasing a laser cleaning machine is a decision that requires comprehensive consideration of many factors. Through detailed analysis of factors such as laser power, wavelength, cooling system, operating interface, portability, brand and after-sales service, cost and safety, users can choose the most suitable equipment.

In the actual purchase process, you can consult industry experts or experienced users to understand the actual use effects of different brands and models, so as to make a more wise choice. At the same time, keeping an eye on the market and technology, and keeping abreast of the latest product and technology trends, will also help you choose a laser cleaning machine with superior performance and high cost performance.