How does waterjet work? Waterjet cutting, also known as water jet cutting, is a technology that uses high-pressure water to cut. It is different from traditional mechanical cutting or laser cutting. Its unique working principle and wide applicability make it show unique advantages in many fields.

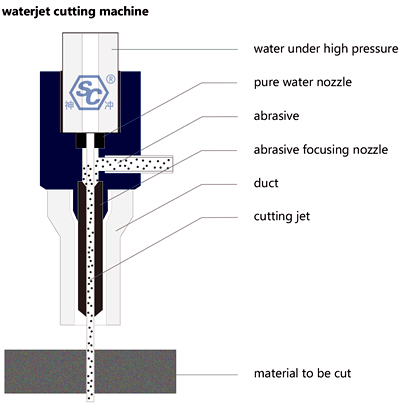

The working principle of water jet is based on two core elements: high-pressure water flow and abrasive.

First, water is pressurized to extremely high pressure by a high-pressure pump, usually up to hundreds of MPa. Such high-pressure water flow is ejected through a special nozzle to form an extremely fine and extremely fast water jet. When this water jet hits the target material, it will generate a huge impact force, thereby achieving the cutting of the material.

However, cutting only by high-pressure water flow will be limited in cutting ability and efficiency. In order to enhance the cutting ability of water jet, people introduced the element of abrasive. Abrasives are usually fine particles with high hardness, such as garnet, aluminum oxide, etc. These abrasives are mixed into the high-pressure water flow and impact the target material together with the water jet. Under the action of the impact force, the abrasive will scrape and grind the surface of the material, thereby greatly improving the cutting efficiency and cutting ability of the water jet.

At the beginning of operation, ordinary water is boosted by a high-power high-pressure pump driven by an electric motor, raising the water pressure to hundreds or even thousands of megapascals (MPa). This process is achieved through a hydraulic transmission system, which includes a plunger high-pressure pump that can convert oil pressure into water pressure.

The electric motor outputs electrical energy and drives the oil pump through a belt drive system, thereby generating high-pressure oil pressure. The high-pressure oil pushes the piston in the booster to reciprocate, converting the oil pressure energy into water pressure energy.

After the pressurized water passes through the accumulator to stabilize the pressure, it is ejected through a nozzle made of gemstone or carbide with a very small diameter (usually between 0.1 and 0.4 mm), forming an extremely fast and highly focused water jet, whose speed can reach more than 3 times the speed of sound.

For cutting harder materials, fine abrasive particles (such as garnet sand, corundum, etc.) can be added to the high-pressure water jet. These abrasives are accelerated to a very high speed to form a water jet containing abrasives, which greatly enhances the cutting ability and can cut hard materials such as rocks, metals, and glass.

The entire waterjet cutting process can be accurately controlled by a computer numerical control (CNC) system, which can cut complex shapes and plane contours and realize automated processing.

In some cases, the water jet can also be cut underwater in a water tank. This working mode can reduce the atomization phenomenon caused by the water jet cutting in the air, reduce noise, and keep the working environment clean.

The cutting accuracy of water jet can reach the millimeter level or even finer, which makes it have unique advantages in occasions where high-precision cutting is required.

Water jet can cut almost any material, including metal, non-metal, glass, ceramic, rubber, plastic, etc. This wide applicability makes water jet widely used in many fields.

Water jetcutting does not generate heat, smoke and harmful gases, and does not pollute the environment. At the same time, the waste after cutting is also easy to recycle and dispose of.

Since waterjet cutting does not generate sparks and high temperatures, it has high safety. This makes water jet more advantageous in cutting flammable and explosive materials.

The cutting speed and cutting depth of the water jet can be precisely controlled by adjusting parameters such as water pressure, water flow rate and abrasive flow, thereby achieving precise control of the cutting process.

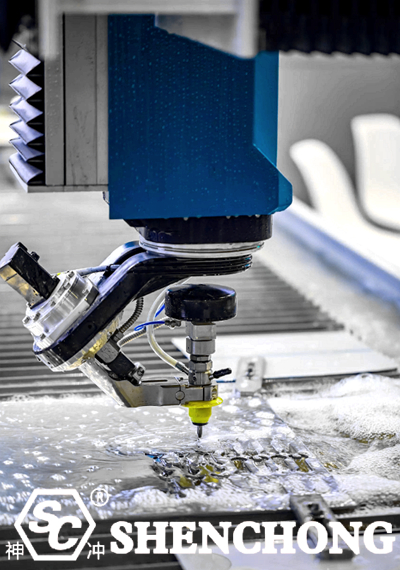

Water jets can create complex shapes and designs, 3D contours or beveled cutouts (with a robot).

Slower than lasers, but just as fast as flame cutting.

Water jet is a device that uses high-pressure water flow and abrasives for cutting. Because of its high precision, fast speed, and strong material adaptability, it is widely used in the cutting and processing of metals, glass, ceramics, plastics and other materials. You need to systematically learn the operation manual and usage methods of the water jet before you can conduct practical training.

Before the water jet operation, preparation work is required, including material selection, measurement and fixation, positioning of water jet cutting points, and equipment inspection and debugging.

Water jet processing is achieved by controlling the running trajectory of the water jet cutting head through CNC programs. Tool path generation is the most critical link in the entire water jet operation process, and is generally achieved using CAD/CAM software.

The cutting parameter settings include nozzle diameter, feed speed, pressure, etc. The settings of these parameters directly affect the cutting quality and efficiency.

First, turn on the water jet equipment and perform operations such as heating and starting. Then load the tool path program on the computer, and preview and debug it. Then perform the actual cutting operation according to the cutting parameter settings, and observe the running status of the water jet and the cutting situation of the material at any time, and adjust the parameters in time.

In the field of industrial manufacturing, water jets are widely used in metal cutting, non-metal cutting, glass processing, ceramic processing, etc. Due to its high precision and wide applicability, water jets have become an indispensable tool for many manufacturing companies.

In the construction industry, water jets are used for stone cutting, tile cutting, glass curtain wall installation, etc. The high precision and environmental protection of water jets make it more and more widely used in the construction industry.

Water jets are also widely used in the field of art production. Artists can use water jets to cut materials of various shapes and patterns to create unique works of art.

In the military field, water jets are used to cut explosives, remove obstacles, etc. Its high precision and safety give water jets unique advantages in the military field.

In scientific research, water jets are also used to simulate the erosion process of water flow on rocks and study the cutting performance of materials. By adjusting the parameters of the water jet and observing the cutting process, scientists can gain a deeper understanding of the properties and cutting mechanisms of materials.

Waterjet cutting machines can cut a variety of foods, including meat, vegetables, bread, etc. Since no heat is generated during cutting, the original flavor and nutrition of the food can be maintained.

Water jet cutting machines can cut a variety of aerospace materials, such as titanium alloys, carbon fiber composite materials, etc. Since no heat and vibration are generated during cutting, deformation and damage of the material can be avoided.

Water jet cutting machines can cut a variety of electronic components, such as printed circuit boards, silicon wafers, etc. Since no heat is generated during the cutting process, damage to components can be avoided.

In addition to conventional waterjet cutting machines, there are some derivative water jet cutting technologies, such as:

Nano waterjet cutting technology is a technology that uses nano-scale water columns for cutting. Compared with traditional water jet cutting technology, nano water jet cutting technology can achieve higher precision and smaller cutting width.

Frozen water cutting technology is a technology that uses frozen water for cutting. Because frozen water has higher density and lower surface tension, it can achieve higher cutting speed and better cutting quality.

Ultra-high pressure water cutting technology is a technology that uses higher pressure water flow for cutting. Compared with traditional water jet cutting technology, ultra-high pressure water cutting technology can achieve higher cutting speed and deeper cutting depth.

In general, waterjet cutting machines have become an indispensable and important equipment in modern industrial manufacturing due to their high efficiency, precision and environmental protection. Whether in metal processing, stone processing, or in the field of glass and composite materials, they have demonstrated excellent application value.Water jet cutting technology continues to develop and innovate, providing more efficient, more precise and more environmentally friendly solutions for material processing and cutting in various fields.