Manufacturing is the economic foundation of a country, which has an important impact on people’s lives. Emerging technologies may have an impact of changing the rules on manufacturing models, methods, concepts, and even companies.

Our next-generation Industry 4.0 promises to increase manufacturing flexibility, while achieving mass customization, better quality, and higher productivity. Therefore, it enables the company to respond to the challenge of producing increasingly personalized products with a shorter time to market and higher quality.

Sheet metal intelligent manufacturing system plays an important role in Industry 4.0. Typical resources are transformed into smart objects so that they can perceive, act, and behave in a smart environment.

Industry 4.0 is a strategic initiative in Germany, which aimed at creating smart factories and upgrading and transforming manufacturing technologies through cyber-physical systems (CPSs), the Internet of Things (IoT) and cloud computing.

In the Industry 4.0 era, manufacturing systems can monitor physical processes, create a so-called “digital twin” (or “network twin”) of the physical world, and make intelligent decisions through real-time communication and cooperation with people, machines, sensors, etc.

Industry 4.0 combines embedded production system technology with intelligent production processes, paving the way for a new technological era, which will fundamentally change the industrial value chain, production value chain and business model.

In the context of Industry 4.0, the manufacturing system has been updated to a new level. Sheet metal intelligent manufacturing utilizes information and manufacturing technologies. It will achieve the manufacturing processes to be flexible, intelligent, and contingent advanced, and respond to the dynamics of the global market.

Physical processes and flows can be used in manufacturing chains, multiple industries, individual suppliers, and large companies when and where they are needed. Ability to learn, change their behavior according to different situations and requirements.

These technologies can communicate directly with the manufacturing system, solve problems in a timely manner, and make decisions. Some technologies also have artificial intelligence (AI), which allows the system to learn from experience in order to finally realize interconnected, intelligent and habitual industrial practices.

Concepts similar to sheet metal intelligent manufacturing include cloud manufacturing and IoT manufacturing. Intelligent manufacturing is a broad manufacturing concept. The purpose is to make full use of advanced information and manufacturing technology to optimize production and product transactions.

It is a new manufacturing mode based on intelligent science and technology, which greatly improves the design, production, management and integration of the full life cycle of typical products.

The use of various smart sensors, adaptive decision models, advanced materials, smart devices and data analysis can simplify the entire product life cycle. Improve production efficiency, product quality and service levels. The competitiveness of manufacturing companies can be improved through their ability to face global market dynamics and fluctuations.

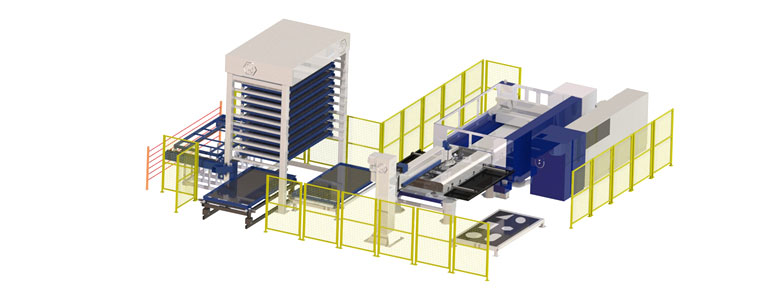

Sheet metal intelligent manufacturing is an integrated intelligent system composed of intelligent machines and human experts. It realizes intelligent activities such as analysis, reasoning, judgment, conception and decision-making in the manufacturing process.

Through the cooperation of humans and intelligent machines, we will expand, extend and partially replace the mental work of human experts in the manufacturing process. It extends the concept of manufacturing automation to flexible, intelligent and highly integrated.

There is no doubt that intelligence is the development direction of manufacturing automation. Artificial intelligence technology is widely used in all aspects of the manufacturing process.

Intelligent Manufacturing System (IMS)

One form of realization of this concept is Intelligent Manufacturing System (IMS), which is considered to be the next generation manufacturing system obtained by adopting new models, new forms and new methods to transform traditional manufacturing systems into intelligent systems.

In the industry 4.0 era, IMS uses a service-oriented architecture (SOA) through the Internet to provide end users with collaborative, customizable, flexible and reconfigurable services, thereby realizing a highly integrated man-machine manufacturing system.

This highly integrated human-machine cooperation aims to establish an ecosystem composed of various manufacturing elements involved in IMS, so that the organization, management, and technical aspects can be seamlessly combined.

By providing typical functions such as learning, reasoning, and action, AI artificial intelligence plays a vital role in IMS. By using AI technology, people’s participation in IMS can be minimized.

For example: materials and production components can be automatically arranged, and production processes and manufacturing operations can be monitored in real time.

With the continuous recognition of Industry 4.0, autonomous sensing, intelligent interconnection, intelligent learning analysis and intelligent decision-making will eventually be realized.

For example: an intelligent scheduling system can make jobs be scheduled based on AI technology and problem solvers, and can be provided to other users as a service on a platform that supports the Internet.

Some people ask the question, will intelligent automation be realized in the next century? If only a certain part of the enterprise is intelligent, the overall optimization cannot be guaranteed, we think the meaning of such intelligence is limited.