Over the decades, technology has vastly advanced and also infiltrating industries. It is now possible to add software technology when processing machines to have more and fast productions.

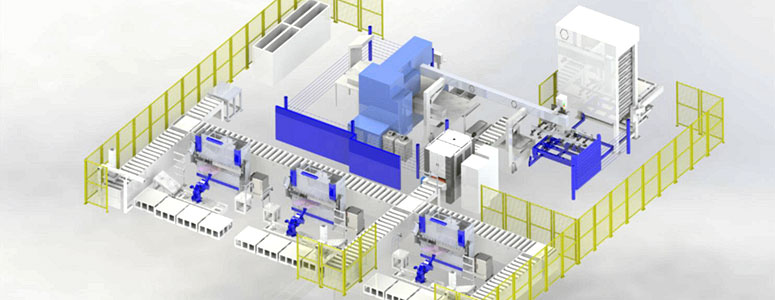

A smart factory contains a series of smart machines that a single system will govern. In the intellignt factory, sheet metal automation machines work in succession to each other. This makes the production process efficient and less laborious. Also, a smart factory allows the production of unique and complex designs presented by the clients, unlike in traditional factories.

Smart manufacturing combines internet software that helps monitor the production and the factory machinery. By using intelligent systems, the process reduces any chance of errors that may occur on the final product.

Unlike traditional factory machinery, the user does not need to counter-check all the products produced in a uniform sequence. Therefore, smart factory vs smart manufacturing provides the user with the perfect solution for mass production, especially in sheet metal industries.

As the world is slowly adapting to smart factories, traditional factories have long been used in sheet metal production. However, their production process is not as efficient compared to smart workshop.

Traditional factories offer more hazardous conditions to the environment due to their waste emissions. Nevertheless, it is a defining factory that smart manufacturing and smart factories are better future solutions.

Smart factories and manufacturers offer a significant reduction in material handling costs, unlike in traditional factories. This is made possible by using automation software on types of machinery that provides precise material productions as instructed. However, for conventional factories, it is proven to be quite challenging to control the exact shapes and sizes produced hence the use of extra costs on materials used in modifying.

For intellignt factories, there is increased agility compared to traditional factories. Automated manufacturing enables the user to change the amount of metal sheet produced depending on the fluctuating customer demands. As for conventional factories, the production rate is constant due to the limited capabilities of the machines used.

Predictable supplies are attained when using the smart factory process in the sheet metal industry. Compared to the enormous amounts of data produced, smart factory machines can acquire the most delicate details required for a product. Whether it’s the colour of the metal sheets or a drawing to be added, automatic machines can adjust easily.

Defining smart manufacturing and the smart factory, you can’t get enough of the vast savings acquired on management cost compared to traditional factories.

Due to the increased rates of global warming, it is advisable that sheet metal industries, among others, advance from traditional ways of production to the new smart factory manufacturing. Waste and other processes are recycled and used accordingly to reduce the amount of disposal to the environment. Smart factories have also proved to be fast in mass production when the need arises.