With the development of science and technology, human society has higher and higher requirements for the function and quality of products, the cycle of product replacement is getting shorter and shorter, and the complexity of products has also increased. Traditional mass production methods have been challenged. This challenge not only poses a threat to small and medium-sized enterprises, but also plagues large and medium-sized state-owned enterprises. Because, in mass production methods, flexibility and productivity are contradictory.

As we all know, only single varieties, large batches, dedicated equipment, stable technology, and high efficiency can constitute economies of scale; conversely, multi-variety, small-batch production, low specificity of equipment, frequent adjustments in the case of similar processing forms With tools and fixtures, the difficulty of process stability increases, and production efficiency is bound to be affected. In order to improve the flexibility and production efficiency of the manufacturing industry at the same time, to shorten the production cycle and reduce product costs under the premise of ensuring product quality, and ultimately to enable small and medium batch production to compete with mass production, a flexible automation system came into being.

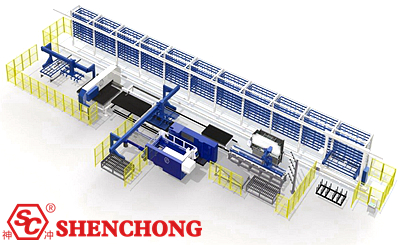

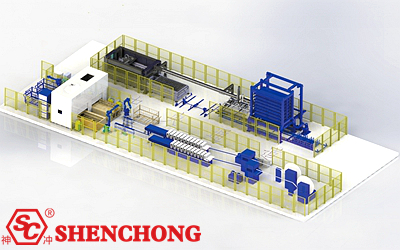

The basic components of the flexible production line of the machinery manufacturing industry are divided into:

Automatic processing system refers to a group of technology based on the overall size (the shape does not need to be exactly the same), roughly similar weight, the same material, and similar parts of the process are processed on one or several CNC machine tools or special machine tools and other equipment. system.

The logistics system refers to a system that is composed of a variety of transportation devices, such as conveyor belts, track-turntables, and manipulators, to complete the supply and transmission of workpieces, tools, etc. It is the main component of the sheet metal flexible production line.

Information system refers to a system that collects, processes, and feeds back all kinds of information needed in the process of processing and transportation, and implements hierarchical control of machine tools or transportation equipment through electronic computers or other control devices (hydraulic, pneumatic devices, etc.).

Software system refers to an indispensable part to ensure the effective management of sheet metal flexible lines with electronic computers. It includes software for design, planning, production control and system supervision. The flexible production line is suitable for small and medium batch production with an annual output of between 1,000 and 100,000 pieces.

The sheet metal flexible line is a technically complex and highly automated system that organically combines microelectronics, computer and system engineering technologies to ideally and satisfactorily solve the contradiction between high automation and high flexibility in mechanical manufacturing.

The specific advantages are as follows.

(1) High equipment utilization: After a group of machine tools are incorporated into a flexible production line, the output is several times higher than the output of this group of machine tools when they are dispersed in stand-alone operation.

(2) The production capacity is relatively stable: the automatic processing system is composed of one or more machine tools. In the event of a failure, it has the ability to degrade operation, and the material conveying system also has the ability to bypass the failed machine tool.

(3) High product quality: During the processing of parts, the loading and unloading is completed at one time, with high processing precision and stable processing form.

(4) Flexible operation: The inspection, installation and maintenance of some flexible production lines can be completed in the first shift, and the second and third shifts can be normally produced without supervision. In an ideal sheet metal flexible line, its monitoring system can also deal with unforeseen problems such as tool wear and replacement, logistics blockage and dredging.

(5) The product's adaptability is large: the cutting tools, fixtures and material transportation devices are adjustable, and the system layout is reasonable, which is convenient for adding or reducing equipment and meeting the needs of the market.

Konw More About 3 Kinds Of Sheet Metal Flexible Lines:

- Laser Cutting Automatic Production Line