The Electrical Servo CNC Press Brake, it is the mainstream trend and featured product in the future. WDK Series Hybrid Servo CNC Press Brake provides more advantages on bending speed, energy saving and working environment.

Now the press brakes on the market are divided into 3 levels. The high-level is Electrical Servo CNC Press Brake, it is the mainstream trend and featured product in the future. The second level is electro-hydraulic synchronous press brake, servo energy-saving type and multi-axis type are the most popular models on the market today. The third level is torsion-bar synchronous press brake, it is about to be the past tense, the market is mostly distributed in underdeveloped countries.

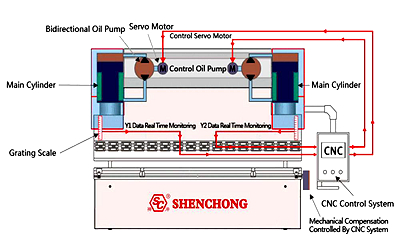

- There is no requirement for the friction between the left and right cylinders and the synchronism of Y1 and Y2. Each servo motor controls one oil pump and cylinder to ensure the maximum accuracy of the slider.

- It saves more than 80-85% electricity.

- High efficient.

- No leakage. Oil won’t be hot even use 24hx7days, so the hydraulic system is not easy to be fossilized and damaged.

- Eco-friendly. The max noise is 20 db. It is silent when standby.

- No failure rate.

- No proportional valve, machine will never vibrate.

- Super high speed. The fastest speed can upto 300mm/s, and machine won’t vibrate. It is suitable for high stroke, high pressure machine.

- Multi-axis available, It can satisfy all your normal work pieces processing.

- Standard MSD laser safety imported from Italy.

- Less person operation. Full-automatically operate.

- More than 6 axis, it can be connected with ROBOT.

To meet customers’ bending requests, SHENCHONG announce WDK Series Hybrid Servo CNC Press Brake, which provides more advantages on bending speed(high speed), energy saving,working environment.

WDK Series press brake is equipped with a touch-screen graphic programming CNC controller and is available in 6 axes in total with 4 axes back gauge. WDK Series is intended and designed for customers looking for better operation experience and Eco production targets.

The whole steel plate of electrical servo press brake is welded, the stress is eliminated by the vibration after tempering sandblasted and sprayed with anti-rust paint. the machine frame is processed by imported CNC three-dimensional processing center, which ensures the parallelism and verticality of each installation.

Adopt split double oil tanks (with independent shockproof buffer layer, better muting effect).

Adopts hybrid servo pump control system: the left and right two sets of magnetic scales send position signals to controller to control two main servo motor and oil pumps by the rotation speed to produce the same flow and pressure, so that the left and right oil cylinders move synchronously and press up simultaneously. The oil cylinder, oil pump, servo motor, magnetic scale, and computer form two closed-loop systems.

The servo motor rotates slightly (quietly and energy-saving) during standby. When it is fast down, the servo motor rotates at different speeds (high speed and low torque) according to different speed requirements. When the machine is bending, the torque of the servo motor is different ( High torque and low speed). During the return stroke, the speed of the servo motor is different (medium torque) according to different speed requirements.

The hydraulic system has overload safety protection, and the oil level is displayed clearly and intuitively. The seals in the oil cylinder are all imported parts, with good quality and strong performance.

Continuous working under rated load, the hydraulic system guarantees no leakage and continuous and stable processing with high accuracy.

- The use of servo motor makes the system low energy consumption in the working gap. The energy-saving effect is excellent. Compared with the model, the energy-saving rate is up to 70%, and the noise is even lower. When electrical servo CNC press brake is running at high speed, the noise value does not exceed 60 decibels.

- The distribution of oil is basically on-demand distribution without throttling loss. It can achieve real energy saving.

- The low temperature rises. When the ambient temperature is 38°C, the continuous working oil temperature does not exceed 50°C, which reduces the risk of oil leakage, has higher stability, and improves the service life of the hydraulic system and cylinder.

- Using a bidirectional gear pump, the machine tool cylinder is determined by the forward and reverse rotation of the gear pump, which reduces the dependence on the quality and stability of the hydraulic valve group. The quality of the machine tool is more stable, and it is most suitable for robots to bend.

- The position accuracy of the slider or the accuracy of the parts is higher than that of the proportional valve control system machine tool. After actual testing, the repeatable positioning accuracy of the slider is ±0.01mm, and the highest accuracy is ±0.005mm.

- The economy is better. The consumption of energy is reduced by 70% compared with the model, which greatly saves power consumption and hydraulic oil consumption.

- The work efficiency is higher. And the efficiency of the electrical servo CNC press brake is increased by up to 30% compared with the same period of the previous year.

Want to know:

Servo CNC Hydraulic Press Brake Machine Technical Development and Applications