Understanding sheet metal bending drawings is crucial for manufacturing processes that involve forming metal parts through bending. These drawings contain specific information that guides fabricators in creating precise bends in sheet metal. Here's a step-by-step guide on how to understand and interpret sheet metal bending drawings.

After getting a bending drawing, first look at the title bar, which contains important information such as the perspective, material specifications, product models, material names, material coding, proportion, unit and other important information. Before bend, be sure to confirm whether the drawings are consistent with the bending work piece. When looking at the bending drawings, you must first distinguish whether it is the first perspective or the third perspective. Generally, it is divided into these two types. Generally, there are symbols in the frame.

Basic Information: The title block provides key information such as the part number, material type, drawing revision, scale, and tolerances. It may also contain details on the customer, designer, and approval dates.

Material Type: Look for the material callout (e.g., aluminum, stainless steel, or mild steel). The material thickness is usually specified in the drawing.

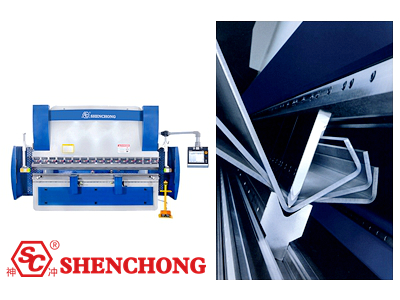

Thickness: The thickness of the sheet metal affects how it bends. Thicker materials may require different tooling or adjustments in bend allowance.

Bend Lines: These are the lines along which the sheet metal is to be bent. Bend lines are often marked with dashed lines on the flat pattern view of the drawing.

Bend Angles: Each bend line will have an associated bend angle. The drawing will specify whether the bend is positive (upward) or negative (downward), as well as the degree of the bend (e.g., 90°, 45°).

Bend Allowance: This refers to the extra material required for the bend due to the metal stretching as it is bent. The drawing may include tables or formulas to calculate this, or it might specify values for each bend.

Bend Deduction: This represents the amount of material removed from the flat pattern to account for bending.

Flat Pattern View: The flat pattern is the unfolded version of the part, showing all features (e.g., cutouts, holes) in their flat state. This view helps fabricators understand where to make cuts, bends, and other operations before forming the part.

Dimensions: Check for the overall dimensions of the flat pattern and the location of holes, cutouts, and bend lines.

Up and Down Bends: The drawing will indicate whether a bend is upward (toward you, marked by an arrow or symbol) or downward (away from you). Some drawings may use “open” or “closed” arrows to indicate direction.

Bend Order: Sometimes, the drawing includes a bend sequence, which tells you the order in which bends should be made.

K-Factor: Some sheet metal bending drawings may include the K-factor, which is a ratio that helps determine the neutral axis shift during bending. This factor influences the bend allowance calculation and can affect the final shape.

Bend Tolerances: These specify the acceptable range for each bend angle. For example, if the bend angle is specified as 90°, the tolerance might allow a range of ±1°.

Dimensional Tolerances: Check the general tolerances section to understand the permissible deviations in length, width, and hole positioning after bending.

Multiple Views: Sheet metal drawings often have different views, such as top, side, and isometric views. These help you visualize the part in 3D. Cross-section views may also be provided to give more detail on specific bends.

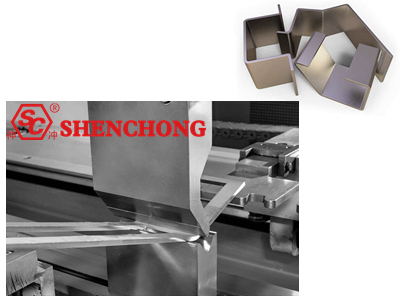

Folded View: This shows the part in its final, bent state and helps you understand how the flat pattern translates into the 3D shape.

Bend Notations: Bends may have symbols such as V, L, or U to denote different types of bends. Some drawings use standardized symbols to represent various processes (e.g., punching, embossing, or notching).

Annotations: Look for notes that give instructions related to tolerances, special processes, or warnings (e.g., specific tooling, heat treatment).

Datum Points: These are reference points used for aligning parts during the fabrication process. They can be essential for ensuring that the bend lines and other features are accurately positioned.

Centerlines: Sometimes the centerlines of the bend are marked to help with alignment during fabrication.

Generally, the first perspective is the standard of drawing. You only need to look at the rules of the projection.

If the drawings from the third perspective, you need to look at which side marked on the drawing. For example, when you look at the images from the left, put it on the left, and the images that you have seen from the right are placed on the right.

Do not miss the local view or section of the face. The corners of the bending drawings must be seen.

The schematic diagram is not as good as the three views. Most of them are represented by lines or thick lines. Generally, you only need to distinguish down or fold it upwards.

Put the bending work piece according to the main view, pay attention to drawing or burrs, so as to facilitate the direction.

At the same time, it is easy to check whether the bending drawings are correct.

It depends on whether the sheet metal processing bending drawing is bent, whether it is solid or dotted.

The solid line refers to the part that can be seen, that is, bending up. The dotted line refers to the invisible part, that is, bending down.

Many sheet metal processing bending drawings are released from 3D software. Therefore, sometimes the bending line is cut into the dotted line. It makes us unable to see whether we need to bend upward or bend down. At this time we need to match the side view to see the bending direction.

When you look at the bending drawings, you can clearly understand the drawings according to the projection rules.

If it is the sheet metal processing drawing of the third perspective, you need to indicate which side is indicated on the drawing.

Looking at the bending drawings not only depends on the whole, but also cannot ignore local views or section.

Due to the product structure, it cannot be displayed in the three views, so local views need to be used. The corners of the drawing must also be paid attention to, which means that the entire bending drawing is the focus, and it must be paid enough attention.

It is also necessary to pay attention to what materials and thickness. Press brake bottom die should be adjusted according to the thickness of the plate. This can be seen on the title bar. Remember to determine whether the bending drawings are consistent with the work piece.

The direction of the burrs is one of the correct means to test the bending drawings. For door panels and box body work pieces, the burrs need to be guaranteed in the opposite side.

When the folding shape is complicated, be sure to determine the best bending order.

If the order is wrong, it may cause the subsequent process to be unable to bend, even if it can be bent, it will affect quality and efficiency.

Some work pieces must not only consider the sequence of bending, but also the type of press brake tooling.

Ensure important sizes. Generally, there are marks in the drawings.

If the materials are abnormal, contact the team leader or engineer in time.

By understanding these elements, you can effectively interpret sheet metal bending drawings, ensuring accurate fabrication and assembly. Familiarity with bending terminology, geometry, and conventions is key to successfully manufacturing parts based on such drawings.