The valve group of the electro-hydraulic press brake is a very important part of the hydraulic system. Electro-hydraulic press brake adopts the proportional valve, how does it work? Why it is better than torsion bar synchronization?

ShenChong professional CNC hydraulic press brake manufacturer will explain it for you now!

Working principle:

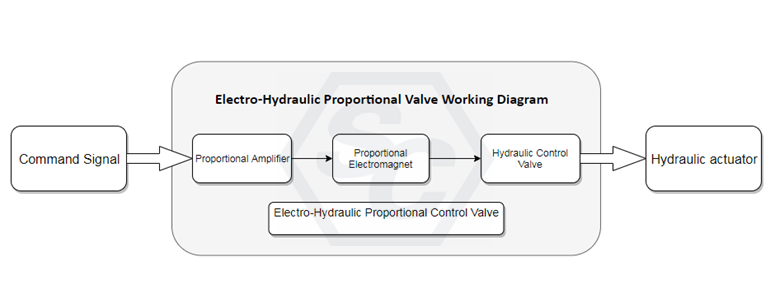

The electro-hydraulic proportional valve is a kind of element that the input voltage signal of the proportional electromagnet in the valve generates the corresponding action.

That makes the valve core of the working valve produce displacement and the size of the valve port change. To complete the output of pressure and flow proportional to the input voltage.

The displacement of the spool can also be fed back in the form of mechanical, hydraulic, or electrical.

Usually, we simply call it a proportional valve. The proportional valve’s application field is expanding day by day. It has been widely used in sheet metal press brake bending industry.

Function:

The main function of the proportional valve is the synchronous positioning of the hydraulic system.

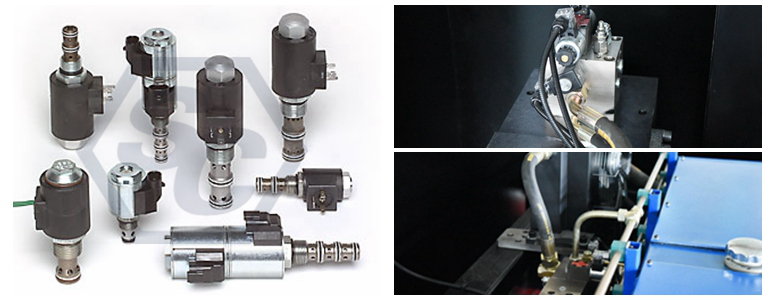

It is composed of DC proportional electromagnet and hydraulic valve.

Electro hydraulic proportional control valve has high-cost performance and good anti-pollution performance.

The core of continuous control of the proportional valve is the use of a proportional electromagnet.

There are many kinds of proportional electromagnets, but their working principles are the same. They are developed according to the need of proportional valve control.

The electro-hydraulic press brake valves include overflow pressure regulating valve, throttle valve, electromagnetic directional valve, filling valve, blocking valve, hydraulic proportional valve, servo valve, etc.

The most important valve is a proportional valve.

Proportional valve operating principle in electro-hydraulic press brake bender

The command signal sent by the control system is amplified by the proportional amplifier. And the current is output to the proportional electromagnet of the proportional valve.

The proportional electromagnet outputs the pressure and moves the spool position in proportion.

Then the flow of hydraulic oil is controlled and the direction of hydraulic flow is changed according to the proportion. To realize the position or speed control of the electro-hydraulic press brake tooling.

In some applications that require high precision of position or speed, we can also form a closed-loop control system by detecting the displacement or speed of the actuator. This is the working principle of an electro-hydraulic press brake machine for sale.

Features of press brake electro-hydraulic proportional valve

– Electrical signals easy to transmit

Realize the remote control of the CNC hydraulic press brake machine simply.

– Continuously and proportionally control the pressure and flow of the hydraulic system

Control the position, speed, and pressure of the actuator and reduce the impact of pressure change.

– Reduce the number of components and simplify the oil circuit

At the same time, the use and maintenance of the electro-hydraulic press brake proportional valve is the same as that of general hydraulic components.

Compared with the servo valve, it has better anti-pollution performance and more reliable operation.

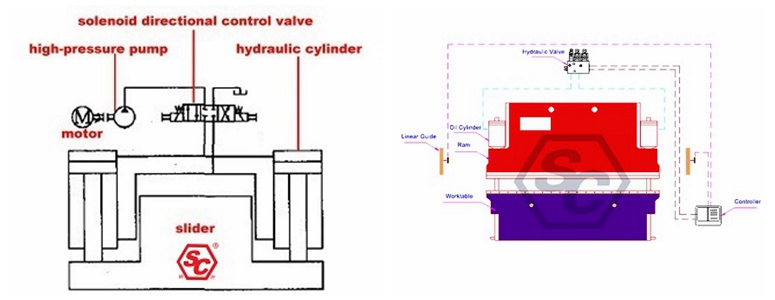

In the past, conventional hydraulic press brake for sale adopts torsion shaft synchronization

Torsion Bar Synchronization: slider synchronous mechanism adopts torsion shaft to force synchronization

Old Wc67y hydraulic press brake bending machine uses the torsion shaft to connect the left and right swing rods, forming a torque forced synchronous mechanism to move up and down the hydraulic press brake cylinders on both sides.

Problems: it is mechanically synchronized through the chain, so wc67y series hydraulic press brake bending machine is a mechanical synchronous mode. At the same time, the position of the two cylinders cannot be automatically checked and adjusted. So there will be many problems with the torsion shaft synchronization.

With the development of science and technology, the hydraulic technology of the bending machine puts forward higher requirements for synchronization. Electro-hydraulic valve synchronous CNC press brake came into being.

Now CNC hydraulic press brakes use electro-hydraulic synchronization

The hydraulic system of the bending machine has the characteristics of high speed, large stroke, many working conditions, high synchronous requirements, and large oil cylinder area.

So CNC hydraulic press brake manufacturers designed and developed a higher performance CNC hydraulic press brake with electro-hydraulic proportional valve synchronization.

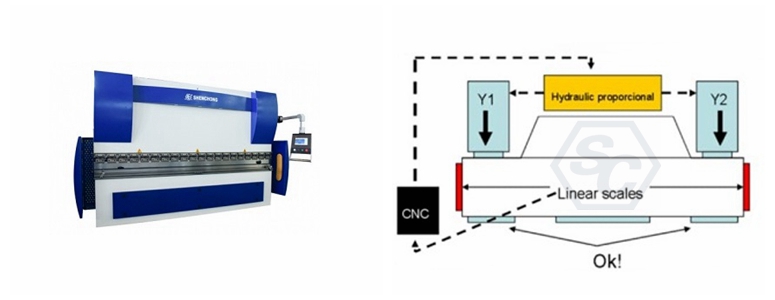

Electro-hydraulic Synchronization: CNC system controls the press brake synchronization through the electro hydraulic proportional system

Numerical control system, hydraulic valve group and magnetic grid ruler constitute the feedback closed-loop control of electro hydraulic valve synchronous bending machine

The electro hydraulic synchronous bending machine is installed with magnetic grating ruler at the hydraulic press brake oil cylinder.

The numerical control system can analyze the synchronization of both sides of the slider through the feedback information of the magnetic grating ruler at any time.

If there is an error, the CNC system will adjust through the electro-hydraulic proportional valve, so that both sides of the slider stroke synchronization.

Electro hydraulic synchronous bending machine is the upgrade of the torsion shaft synchronous series.

The capacity of standard hydraulic press brake unbalanced load is poor. If the load is deflected for a long time, it will cause the torque shaft to deform.

As the using time increasing, the parallelism of the slider becomes worse and worse.

And the torsion shaft synchronous NC hydraulic press brake itself can not make automatic adjustment.

The CNC electro-hydraulic press brake is controlled by the computer through the electro hydraulic proportional valve control closed-loop system to control the synchronization of the machine tool. It can carry out unbalanced bending.

Therefore, electro-hydraulic proportional valve synchronization is better.

– More advanced structure and working principles.

– Comfortable operation with modern technology.

– Better parallel degree of slider. Higher positioning accuracy of back gauge.

– Cylinder compensation or mechanical compensation can be added to improve straightness.

– Whole closed-loop feedback control synchronization of the electro-hydraulic servo system. More stable and reliable operation.

– Electro-hydraulic press brake machine Y1 axis and Y2 axis can be programmed separately to work under an unbalanced load.

– Fast down and slow down functions, and smooth conversion, greatly improving production efficiency.

– CNC Electro-hydraulic press brake uses a numerical control system. Easy to operate.

– With the function of slow return control, the operator can better control the workpiece.

– More suitable for large-stroke, high-speed, high precision bending machines.

– More efficient. The working efficiency of one electro hydraulic synchronous CNC hydraulic press brake for sale can be equal to that of two or three torsion shaft synchronous NC standard hydraulic press brakes.