Now on the market, sheet metal press brake we used mainly includes professional manufacturers produced, second-hand and home-made. Compared with the used press brake machine and DIY metal press brake machine, the press brakes designed and made by professional manufacturers are more efficient, safe, and stable.

Then, we do a detailed analysis and comparison for you. This will be of great help for you to select and purchase the bending machine.

Most of the hot sale press brake machines on the market are designed and produced by professional factories. Nowadays, the press brakes produced by top manufacturers are almost vertical hydraulic type. You can choose small or large; NC, CNC or robotic.

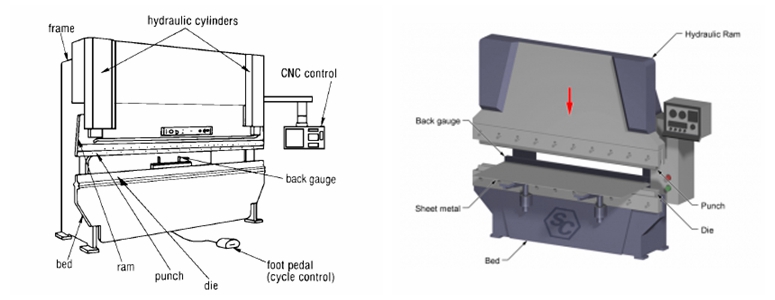

Machine Frame:

– The whole machine body is welded with steel plate, and the stress is eliminated by vibration after tempering.

– The press brake machine is sandblasted and sprayed with antirust paint.

– The bending machine frame is clamped and formed by the imported CNC three-dimensional machining center to ensure the parallelism and perpendicularity of each mounting surface.

Drive system:

– Adopt advanced hydraulic system, including torsion shaft, electro-hydraulic, and servo hybrid.

– Stable transmission and reliable operation.

– Electro-hydraulic servo system: full closed-loop feedback control synchronization.

Control system:

– NC, CNC, Robotic

Press Brake Axis:

The standard configuration is (4 + 1) axis, also multi-axis available: 4 axis, 5 axis, 6 axis, 7 axis, 8 axis

– Y1 and Y2 axes control the numerical axes of oil cylinders on both sides

– X-axis controls the movement of the rear stop

– R-axis controls the up and down movement of the rear stop

– V-axis is the table compensation

Press brake produced by professional manufacturers has the following advantages:

– Higher quality, ISO9001, CE and all other certifications as quality trust endorsement

– Longer service life, lower failure rate

– More beautiful appearance and more advanced technology

– Customized according to your special needs (your plate thickness, length and material type)

– More humanized. Better meet the requirements of users

– More convenient to repair and maintenance

– Easier to purchase accessories

Press brake produced by professional manufacturers has the following advantages:

– More accurate and higher

– Safer operations and more stable reliable work

– More professional and efficient metal forming

– Higher consistency of processed workpieces

– More suitable for mass production

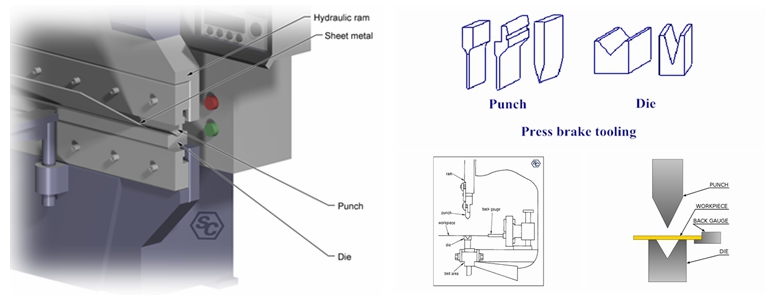

– Professional machinery with metal sheet press brake dies can complete a variety of complex processing

– With professional technical support, maintenance and after-sales service personnel.

– More kinds of metal sheet press brake tooling to choose from or customize

– The price is slightly higher.

– Higher requirements for operators. Need professional bender operators to work.

– The machine is larger and requires a more spacious workshop to work.

– CNC hydraulic press brake production cycle is long, need to order in advance.

– The production cycle of Shenchong CNC press brake is about 45 days. Friendly reminder: if there is any demand, please order as soon as possible!

– Regular enterprises and factories will choose the certificated press brakes for sale.

– For the factory with a certain production scale and output, the machine of professional press brake manufacturers will have more advantages.

– When your capital and strength allow, we strongly recommend that you buy professional manufacturing CNC hydraulic press brake for sheet metal.

– Purchasing a new high-end bending machine can not only improve work efficiency and product quality, but also help the factory development and promote the corporate image. Don’t hesitate, this is your best choice!

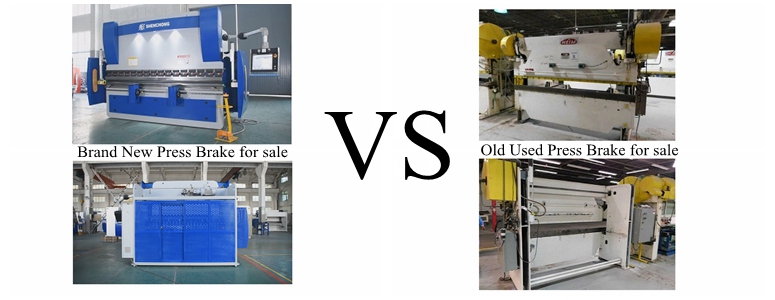

Many customers will purchase second-hand bending machines due to a lack of funds. Some well-known brands used sheet metal press brake still have a certain audience, the market is also very large. If you are interested in second-hand press brake machines, please read on.

– Used press brake are common models and can not fully meet the needs of different users.

– Generally, the types include manual metal press brake, NC hydraulic metal press brake, and CNC sheet metal press brake.

– Used machines tools are usually middle and low end. For example, the used hand metal press brake is popular in India.

– As a new customized sheet metal press brake bending scheme in recent years, there are hardly second-hand automatic robotic sheet metal press brake bending equipment.

– According to your requirements, we can transform your original old CNC plate bending machine into a robotic press brake bending automatic production line. However, there are no mature second-hand robotic bending production line plans for sale on the market.

– Low price

– Buy a famous brand press brake at a lower price

– The quality of some big brand used press brake is even better than the inferior brand new machines.

– Higher press brake working failure rate

– Shorter using life

– Can’t customize according to your needs

– Inconvenient for maintenance

– Difficult to repair and buy accessories

– The appearance is rather shabby.

– Unable to get comprehensive professional after-sales service

– Second hand bending machines are old machines, relatively backward.

– Can’t keep up with the trend of the times. The used press brake's bending technology is not advanced.

– The seller can not provide long-term effective and professional technical support and repair, and other after-sales services.

– If you much love a famous brand and don’t have so much money, you can choose the second-hand used press brake machine tool of that brand.

– When purchasing second-hand press brakes, please be sure to fully understand the previous use and maintenance.

– Considering the cost performance, we suggest that users choose brand-new CNC press brake machines with good quality. More information about the new CNC press brake for sale, you can ask sales for the pictures, PPT, and video.

– Most second-hand machine tools' quality and performance are not reliable, please consider carefully!

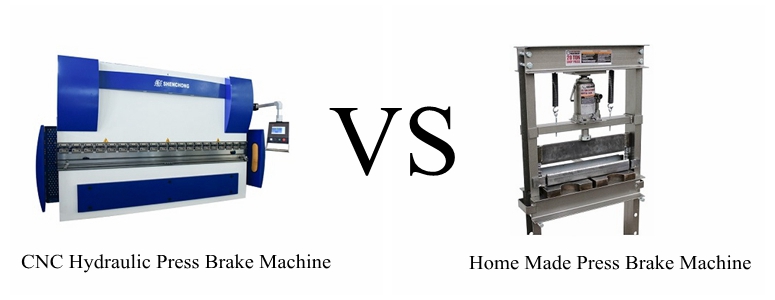

In many Europe, America, and Southeast Asia, homemade press brake DIY is very popular. Especially in some small workshops, we can see many homemade bending machines. Do you think it’s easy to DIY a simple machine? Not really!

– Mainly mechanical hand press brakes.

– The structure of the machine is very simple.

– It’s all for manual work. Very easy to operate.

– You can go online search, a homemade press brake machine is very low-end.

– Just a little investment, save costs.

– Self-made bending machines are all simple small sheet metal press brakes.

– Small size and less space. Suitable for small work areas such as small workshops or front shop.

– DIY according to your needs and preferences. And you can adjust and modify it at any time.

– Do you know how to make a press brake? Sheet metal press brake technology is very complex. It is difficult to make a press brake by yourself.

– Sheet metal press brake DIY needs very professional knowledge and skills.

– It also costs to design and make a machine tool successfully. It costs a lot to study and experiment in the early stage.

– DIY can only make a small machine, can not do large one

– No testing and certification by any professional organization. Quality and performance cannot be guaranteed. Do you dare to use such a machine? Too much risk!

– In common, they are manual mechanical press brakes. Low precision and working efficiency.

– The most serious problem is that the work is very unstable and prone to safety problems.

– Need a lot of manual work. The operation is time-consuming and laborious.

– Can complete some simple sheet press brake forming.

– Only suitable for small workpieces and small batch production.

– If you are a very professional press brake industry engineer, you can try. We don't recommend nonprofessional personnel to do it.

– Unprofessional bending equipment is not only dangerous in manufacturing, but also has high danger and risk coefficient in operations.