Fixture is a tooling or tool used to fix the processing object or connecting part in the process of mechanical manufacturing or equipment installation. Its function is to fix the processing object or connecting part in the correct position for quick, convenient and safe realization. Install cards and fix work.

The clamp set in the cnc press brake machine is generally used to clamp the upper mold. Since the bending machine needs to change the mold frequently, a quick clamping is required, which can be quickly assembled and fixed.

Due to the improper installation of the tool, it will directly affect the accuracy of the bending, resulting in defective products during the bending process.

As the tool installation is too troublesome, constant debugging also affects the efficiency of production.

In summary, the quick press brake tooling clamps came into being.

In fact, this product is no longer unfamiliar with current bending machine equipment. It is the most important product for the installation of bending machine tools, which can effectively, quickly and firmly fix different press brake tools to improve efficiency.

The upper die cutter of the general press brake is installed on it by the quick clamping. And the specific number will vary according to the specifications of the bending machine.

Now that safe production is more and more important, how to use the press brake tooling clamps correctly is very important for end users as well.

– When changing the tooling, the upper and lower die of the bending machine are separated.

– At this time, it is necessary to ensure that the machine is stopped, preferably in a power-off state, to prevent safety accidents.

– Twist the handle on the quick clamp. At this time, it must be operated by two people, and the two quick clamps of the two-end bending machine must be kept closed.

– When the quick clamps of several bending machines are opened in the back, the stability of the tools can be maintained to open the rotary handle of the quick clamps of the bending machine to prevent accidents caused by accidental dropping of the tools.

– Move the replaced tool to the upper die, and then quickly close the rotary handle of the bending machine template to allow it to fix the tool.

– Then turn on the power supply of the press brake to perform product bending operation.

The CNC press brake tooling clamps have the purpose of facilitating mold clamping and adjusting the mold force uniformly, and also prevents damage to the upper slider.

The tool is directly fastened to the slider with screws without installing the mold splint of the bending machine, and long-term use can cause the deformation of the slider.

If the bending part is longer, the situation will be better.

On the contrary, if small parts are often bent at the same position, after long-term use, the slider in the local bending area will be deformed, causing the upper and lower dies to fail to align during bending.

According to different needs, the Shenchong press brake factory will be equipped with different tooling clamps for customers to choose: general grooved quick clamps, imitation Amada-type quick clamps and double-sided double-opening quick clamps.

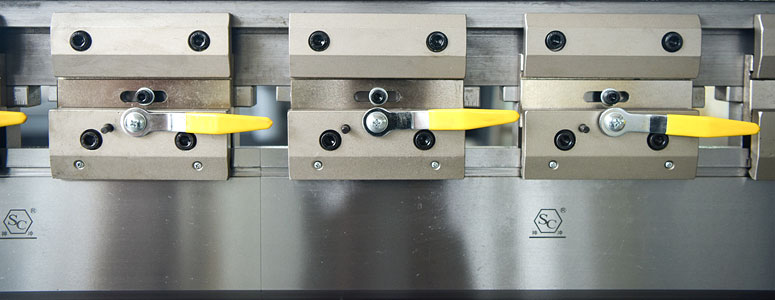

– Universal quick clamp

The universal quick clamp is suitable for most press brake machines, and is equipped with an ergonomic handle.

It makes the opening and closing of the splint easy and convenient. It is convenient for customers to switch molds quickly.

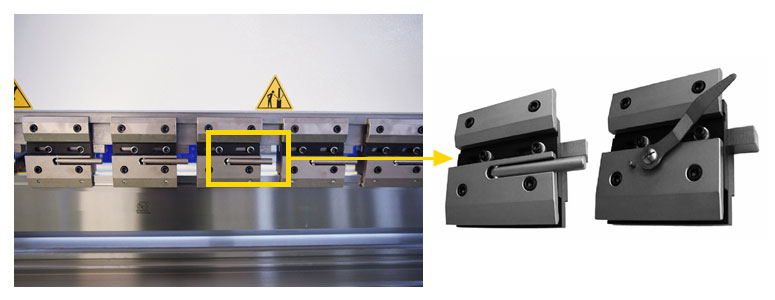

– Imitation Amada-type quick clamp

The imitation Amada-type fast clamp can be adapted to the clamping opening of the European model. It has three safety locks, more safe and reliable.

When the three locks are opened at the same time, it can be installed quickly and quickly according to the bending requirements. Single-piece mold, very fast, greatly improving production efficiency.

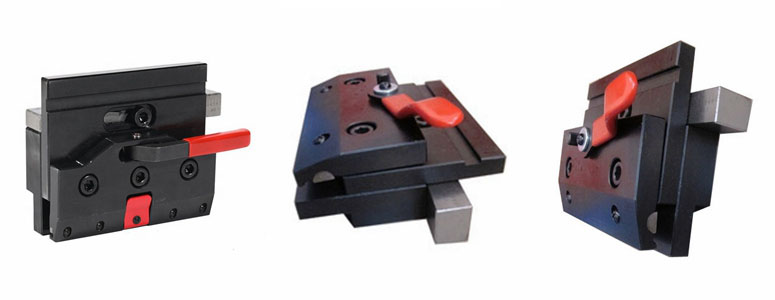

– Double-sided double-opening quick clamp

The double-sided double-opening quick clamp adopts the design of the hook body and the supporting arm on the hook body. The structure is simple, and the use is safe and reliable. Only need to hook one end with the hook body during use, and lightly tap the lower end of the support arm to lock the corresponding size .

At the same time, due to the arc design of the long arm of the hook body, the holding force is greater. The design size of the supporting arm sleeve hole is corresponding to the cross-sectional area of the long arm of the hook body. That is convenient to use without falling off.

The design of the movable splint at the lower end of the support arm. It is easier to find the blessing surface when using it. Safe and stable. It is an ideal tool to ensure the bending quality, improve the bending efficiency, reduce the work intensity of workers, and shorten the production cycle.