Press brake is one of the commonly used sheet metal equipment. However, during the bending process, affected by the tooling, bending pressure and other factors.

The folded plate often produces bending trace, especially aluminum and stainless steel plates are more prone to indentation. These traces will seriously affect the appearance of the product.

The traditional bending process is more likely to cause damage to the surface of the work piece. And an obvious trace or scratch will be formed on the surface in contact with the tooling.

That cannot be removed, resulting in scrapped parts. Therefore, the user’s demand for seamless bending is becoming stronger and stronger.

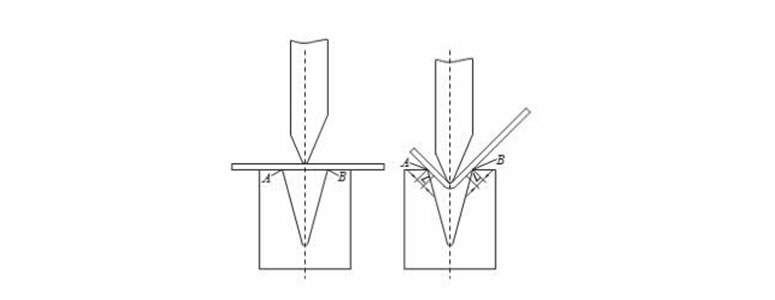

So what is the cause of the trace when bending? Most press brake use V-shaped die, the left picture is before bending, the right picture is in bending.

Points A and B are the stress points of the sheet, and creases usually appear at points A and B.

When bending, the upper punch falls, and the plate slides along two points A and B. L is the sliding range, which is also the place where trace is most likely to occur.

If the manufacturer adopts a coating method to avoid press brake bending trace, the protective film is easy to rupture as the bending pressure changes. Once the protective film is broken, trace will occur.

Let’s talk in detail about the influence of tooling parameters on bending trace.

– Influence of V opening size

When bending metal sheets of different thicknesses, the opening size of the lower die V selected is different.

Under the conditions of the same plate thickness and the same upper punch, the larger the size of the V opening, according to the principle of three-force balance.

The smaller the pressure between the metal sheet and the shoulder of the V opening, the smaller the friction and the trace. The depth is also naturally reduced, so it is recommended to use a slightly larger V-opening lower die.

– The influence of rounded corner R value

In the case of the same V opening, the size of the rounded corner R value is different. And the friction force caused to the plate during the bending process of the plate is different.

The larger the R angle, the smaller the pressure between the plate and the V opening shoulder, and the smaller the trace, and vice versa.

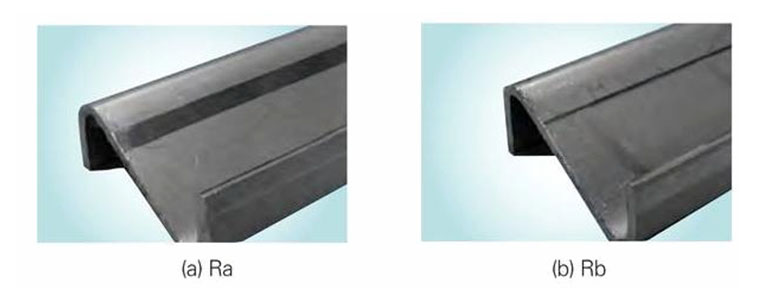

As shown in the figure below, the indentation test chart of the same plate with different R values (Ra<Rb).

Obviously, the bending indentation of Ra is obviously more than that of Rb. Therefore, it is recommended to choose a lower die with a slightly larger rounded corner R.

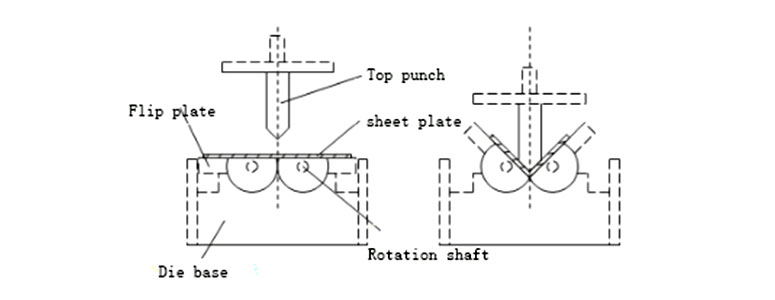

– Roller type V die

The main working principle of this kind of die is that the upper punch falls, the rotating shaft rotates, and the flip plate is turned over.

It is precisely because of the turning of the turning plate that the work piece is in full contact with the lower die without any sliding range, which avoids bending trace.

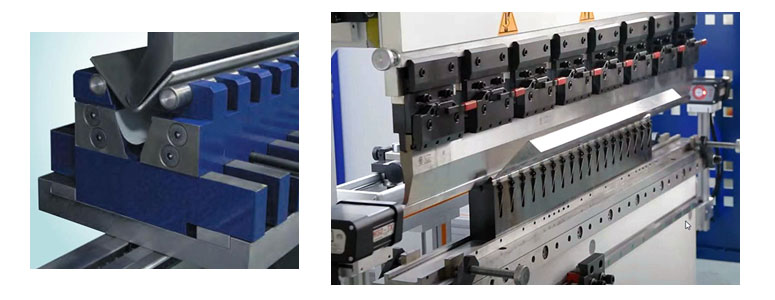

– Roller type adjustable V port

Also based on the principle of reducing the friction coefficient of the friction pair between the plate and the lower die V opening, the sliding friction pair between the plate and the lower die V opening shoulder can be transformed into a rolling friction pair, thereby greatly reducing the friction force on the plate and effectively avoiding the occurrence bending trace.

At present, this process has been widely used in the tooling industry. The die is equipped with hardened rollers with low friction coefficient, which can greatly reduce the external trace of the bending parts. At the same time, it can reduce the bending force by about 10%~30% compared with the traditional lower die.

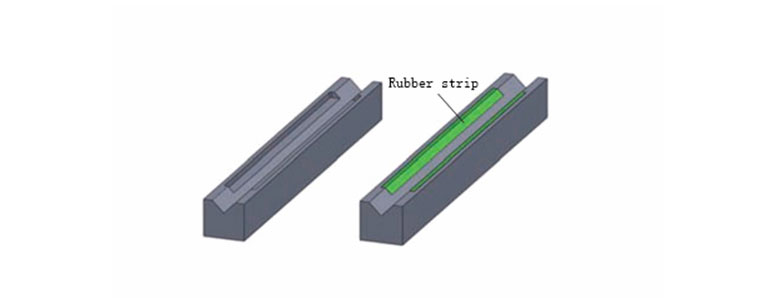

– Replaceable rubber strip V-shaped die

The principle of the die is to open a gap on both sides of the common V-shaped die, and insert a rubber strip in this gap.

During the bending process, the sheet is in contact with the rubber strip. The hardness of the rubber strip is much lower than that of the ordinary lower die, so as to avoid the press brake bending trace.

– Non-marking pressure film

From the perspective of the friction pair, by avoiding the direct contact between the upper and lower molds and the plate, the no-trace film can be used to separate the upper and the no-trace film mainly to buffer between the workpiece and the shoulder of the lower die.

It functions and reduces the coefficient of friction, offsets the pressure between the die and the plate, thereby preventing the workpiece from producing trace during bending.

The no-trace film has the advantages of low cost and convenient use. When using, only the no-trace film is placed on the lower die.

The market competition in the sheet metal processing industry is very fierce. If companies want to occupy a place in the market, they need to continuously improve their processing technology.

It is not only necessary to realize the functionality of the product, but also to consider the manufacturability and aesthetics of the product, as well as the economics of processing. Through the application of more efficient and economical process methods, the product is easier to process, more economical and more beautiful.