A welding production line usually consists of multiple welding stations, each with different welding equipment and tools. These devices can include welding machines, welding fixtures, welding guns, welding wires, and shielding gases.

During the welding process, the workpiece is placed in the welding fixture and different metal components are connected together using a welding gun. Welding wire, as a filler material, melts and fuses with the base material to form a joint. Protective gas can prevent oxygen and nitrogen in the air from reacting with molten metal, affecting welding quality.

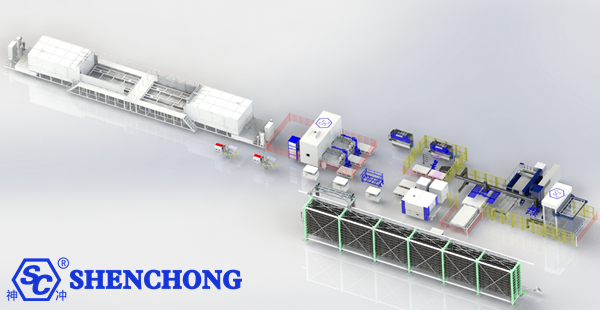

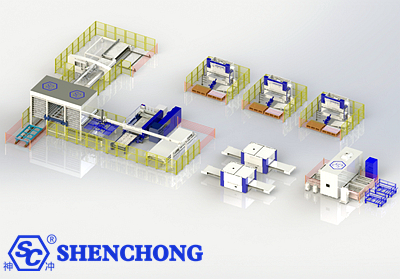

The sheet metal reinforcement welding assembly line equipment customized according to customer needs adopts an automatic assembly line conveying structure. It can be equipped with a reinforcement forming machine and a door panel rolling machine to form a fully automatic production line, realizing automatic feeding, automatic combination, automatic welding, automatic discharge and other processes of sheet metal reinforcement and door panels.

The door panels are automatically fed and transported to the welding position through an assembly line, and the reinforcing ribs are fed through an automatic robotic arm. After welding, the material is automatically cut off, achieving fully automatic production, reducing manual labor and improving production efficiency

The welding process adopts a medium frequency power supply for welding, which maximizes the welding strength and appearance requirements for welding the rear door panel sheet metal, further improving the production qualification rate.

Automatic feeding: Door panels and reinforcing ribs are transported in a streamlined manner.

Automatic combination: The mechanical arm clamps the reinforcing ribs and combines them with the door panel for fixation.

Automatic welding: Multi head automatic spot welding.

Automatic discharge: The welding is completed and the material is automatically transported and discharged.

Sheet metal welding production line is an indispensable and important link in the manufacturing industry. Through reasonable equipment selection, control and monitoring systems, as well as regular maintenance and upkeep, the normal operation of welding production lines can be ensured, and product quality and production efficiency can be improved.

The above has introduced the performance characteristics of sheet metal welding production lines to everyone. Next, we will further introduce the specific functions of the sheet metal welding production line.

What are the applications of sheet metal welding production lines? The sheet metal industry has shown a trend of diversification and automation, and the welding demand and quality in the sheet metal industry are increasing.

Sheet metal welding production lines can replace manual welding to achieve automation in production, without the need for manual intervention in production, effectively reducing the labor intensity of workers and preventing the occurrence of occupational diseases. What are the applications of sheet metal welding production lines?

- Beneficial for improving welding efficiency. After sheet metal enters the automated production line, multiple welding robots can perform welding simultaneously, greatly improving production efficiency.

The production of a car is made up of thousands of different sheet metal parts that are welded and assembled through various processes. The manual operation is accompanied by physical fatigue and environmental factors, resulting in uneven welding quality.

However, the quality requirements for sheet metal welding points are high. The sheet metal welding production line arranges welding tasks for each welding robot to weld in their respective positions, achieving precise welding of each part and stable welding quality.

The sheet metal welding production line has a high level of automation and intelligence. During welding work, the expected welding effect is achieved through offline programming and teaching, reducing the occurrence of welding defects and saving welding materials, thereby reducing enterprise cost expenditures.

Workers carry out welding work in the sheet metal production workshop, and the noise and radiation from welding operations can cause occupational hazards to workers. The automation level of the sheet metal welding production line is relatively high, and the welding process does not require manual participation, which can liberate workers from heavy work.

The production line is composed of multiple welding robots, and enterprises can extend the service life of welding robots through daily maintenance work, which brings greater output benefits to the enterprise.

The above is the application of sheet metal welding production lines, where multiple welding robots cooperate with each other to assist in completing welding tasks, improving welding production efficiency while ensuring quality, and delivering a qualified job to the sheet metal manufacturing industry.

It has saved a lot of energy and labor costs for enterprises, promoted their further development and growth, and played a significant role in the rapid development of the sheet metal manufacturing industry. Let's look forward to the new performance of the sheet metal welding production line together.