As we all know, the bending process is a key process in the sheet metal cabinet processing and forming process, and plays an important role in the entire sheet metal cabinet processing process.

The sheet metal bending process is still regarded as the "bottleneck process" in the sheet metal cabinet processing process in many factories. Because it seriously affects the rhythm balance between the upper and lower processes of the sheet metal pre-processing unit.

In the process of sheet metal cabinet processing, it is particularly important to improve the efficiency of the bending process. So do you know what is the production process of sheet metal cabinets? How to improve the bending efficiency of sheet metal cabinet processing?

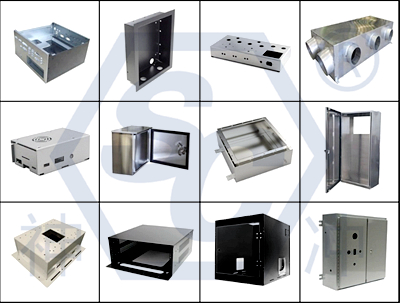

Every product starts from scratch and goes through several processes before the finished product is finally displayed in front of everyone. So do you know the manufacturing process of the sheet metal cabinet that is the most common in our offices? Today, I will share with you the production process of sheet metal cabinets!

We need to use a plate shearing machine to cut cold rolled steel plates into different sizes. According to different metal cabinet products and different cabinet panel positions (such as door panels, side panels, top panels, bottom panels, partitions, etc.), the size of the cut metal panels will also be different.

We use a punch press machine to remove the corners from the cut sheet metal. Different metal cabinet locations (such as door panels, side panels, tops, bottom panels, partitions, etc.) have different beveling styles. There are special molds for dehorning, and large factories generally use assembly line dehorning.

Use a plate bending machine to bend the metal plate with the corners removed. Depending on the location of the metal cabinet, the bending angle is also different.

After folding the side panels, top, middle panel, bottom panel, back panel, slides, partition beams, etc. of the metal cabinet, we need to use a spot welder to spot weld them. Different products are produced according to different metal cabinet styles. At this time, the entire metal cabinet is ready.

If you use a traceless spot welding machine for spot welding, the surface of the spot welded product will be smooth. No need to sand or putty.

Pickling and phosphating the spot-welded integral metal cabinet to remove grease and rust from the surface of the metal plate to prepare for the next steps.

Put the cleaned metal cabinets into the spraying workshop for spraying. Nowadays, electrostatic powder spraying is generally used. The products produced have no pungent smell and are green and environmentally friendly.

The color of metal cabinets is generally gray and white. Each manufacturer uses different powders and different powder batches. Generally there will be some color difference. The sprayed product needs to be heated at a high temperature of 180-200 degrees Celsius.

Then, we can transport the sprayed products to the assembly workshop for assembly. In the assembly workshop, we need to debug partitions, slides, upper drawers, door panels, etc.

After the assembly is completed and the quality inspector inspects it, it can be packaged. After packaging, the steel cabinet products can be sorted into the finished product warehouse.

The bending process is a key factor in achieving high-efficiency processing. Optimizing the bending process of sheet metal cabinet processing includes adjusting the bending angle, selecting the appropriate bending sequence, optimizing the bending parameters, etc.

By adjusting the bending angle and selecting the appropriate bending sequence, we can mprove the bending efficiency and processing accuracy. Optimizing the bending parameters can improve the strength and stiffness of the bending and ensure the smooth progress of the bending process.

Automated processing is an important way to achieve sheet metal cabinet processing and bending efficiency. An efficient and high-precision bending process can be achieved through automated processing.

Automated processing can use robots or automated production lines to achieve automation and intelligence in processing, improve production efficiency and reduce production costs.

Reasonable planning of the processing process is also an important means for the efficiency of sheet metal cabinet processing and bending. During the processing of sheet metal cabinets, reasonable arrangements and planning need to be made according to the processing needs of different needs. Ensure the smooth progress of all aspects, thereby improving the efficiency and accuracy of the entire sheet metal cabinet processing process.

Bending equipment is the core of bending processing in the processing of sheet metal cabinets. Choosing the right bending equipment is crucial to achieving efficient processing.

Different bending equipment is suitable for different processing needs. For example, manual bending machines are suitable for small-scale processing and bending with high flexibility. The automated bending machine is suitable for large-scale processing and high-precision bending.

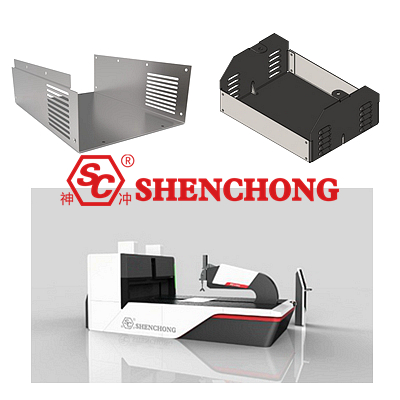

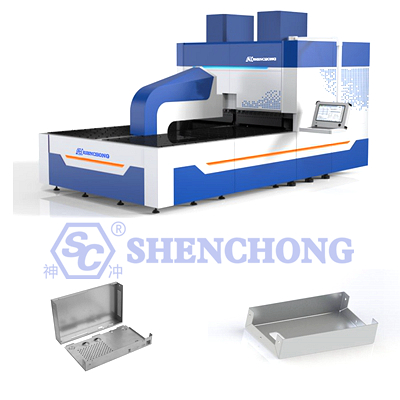

Intelligent flexible bending center sheet metal bending does not require molds and can bend various complex shapes. The bending center can bend complex shapes in various combinations such as right angles, non-right angles, arcs, upper and lower bends, etc., and is used in the metal forming field of different workpieces in different industries.

The equipment is equipped with a pure electric servo system, replacing hydraulic drive. SC bending center has the advantages of environmental protection, fast speed, high precision and maintenance-free.

Domestic steel cabinet shell field, such as cabinets, tool cabinets, electrical cabinets, etc. The plate materials are mostly cold-rolled plates and stainless steel. In the bending process, how to complete the requirements of mass production with high quality and efficiency?

Common cabinets on the market are mainly composed of door panels, bottom panels and other parts. The bending process of workpieces with different structures is also different. Using traditional bending equipment requires re-opening molds according to different types of bent workpieces, which undoubtedly increases mold costs and production time costs.

Click here to know:

The flexible bending center adopts a universal bending mold. A set of molds consists of four knives: upper and lower folding knives, and upper and lower pressing knives. Therefore, the steel cabinet shell bending center can easily meet the bending needs of different types of workpieces.

In terms of production efficiency, the flexible bending center can process one step in 0.2 seconds. Make a workpiece in 30 seconds. 24-hour non-stop bending production. In the face of mass production, flexible bending centers can show even more advantages.

Advanced instructions:

If the workpiece interferes with the bending process, custom bending actions are supported. Supports inserting advanced instructions at any step to perform any required action.

The flexible bending center sets the bending angle through the combination of upper and lower bending instructions. In this process, the 45° hems are all upper hems. Through continuous bending of multiple knives, the process goals are achieved.

Fully automatic loading and unloading:

In addition to the above two typical bending process solutions, a fully automatic loading and unloading solution has also been launched. A flexible bending center equipped with two robotic arms controlled by a multi-axis concurrent linkage intelligent CNC system. The bending efficiency reaches a new level while greatly saving labor costs.

Multilateral flexible bending machines can be used in new energy, home appliances, electricity, western kitchens, elevators, communications, network computer cabinets, medical machinery, fashionable home furnishings, sheet metal processing, etc.

To sum up, we can see that improving the bending efficiency of sheet metal cabinet processing requires starting from many aspects, including optimizing the bending process, using automated processing, rationally planning the processing process, and selecting suitable bending equipment. Through the combined use of these methods, the efficiency and accuracy of sheet metal cabinet processing and bending can be greatly improved.