With the advancement of science and technology and the acceleration of the modernization process, people's requirements for handling speed are getting higher and higher.

Traditional manual palletizing can only be used in situations where the material is light, the size and shape change is large, and the throughput is small. This is far from meeting the needs of the industry, and the palletizing robot came into being.

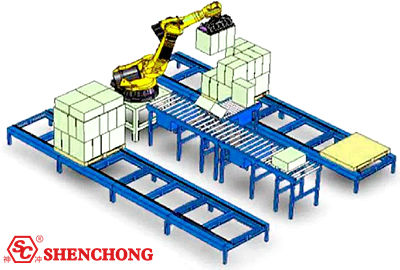

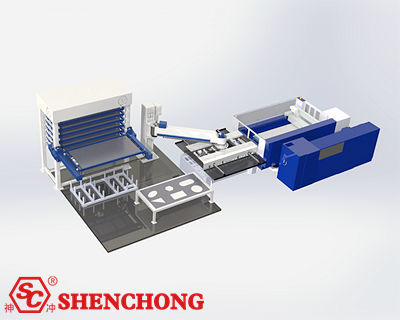

Automatic Loading and Unloading System

Palletizing robots are the product of the organic combination of machinery and computer programs. Provides higher production efficiency for modern production.

Palletizing machines are widely used in the palletizing industry.

The palletizing robot greatly saves labor and space.

The palletizing robot operates flexibly and accurately, quickly and efficiently, with high stability and high operating efficiency.

The palletizing robot system adopts the patented technology of the coordinate robot, and the installation space is flexible and compact. The idea of being able to build an energy efficient and fully automatic block making machine line in a small footprint becomes a reality.

A palletizing robot is a robot that neatly and automatically stacks (or unpacks) the packaged goods on the pallet. Its appearance in practical application greatly improves productivity, reduces the work intensity of workers, and also plays an effective role in guaranteeing the personal safety of workers in individual harsh working environments.

Palletizing on the production line is to stack the goods neatly in a certain order and level. The palletizing robot is a device that replaces manual intelligent palletizing with machines at the end of the production line. The palletizing robot automatically stacks the products in bags, boxes or other packaging shapes conveyed by the conveyor into stacks according to the working method required by the customer's process. It can replace people's work in dangerous, toxic, low temperature, high heat and other harsh environments; help people complete heavy, monotonous and repetitive labor, improve labor productivity, and ensure product quality.

- The palletizing capacity of the palletizing robot is much higher than that of the traditional palletizing machine and manual palletizing.

- The structure is very simple, the failure rate is low, and it is easy to maintain and repair.

- The main components are few spare parts, and the maintenance cost is very low.

- The power consumption is low, and the power consumption is about one-fifth of the mechanical palletizer.

- The palletizing robot can be set up in a narrow space, with high efficiency in site use and flexible application.

- All operations can be done by hand on the control cabinet screen, and the operation is very simple.

- The application of palletizing robots is very flexible, and one robot can handle products from multiple production lines at the same time.

- The stacking type and the number of stacking layers can be set arbitrarily, and the stacking type is neat, which is convenient for sheet metal storage and transportation.

In short: The advantages of strong working ability, large scope of application, small footprint, high flexibility, low cost and convenient maintenance make it widely used and become a development trend.

In order to be able to adapt to changing product requirements for palletizing and make palletizing robots serve the industrial manufacturing industry as well as possible, the future development trends of palletizing robots are as follows:

1)The degree of automation and intelligence is getting higher and higher

Electromechanical integrated technology will become the mainstream of the development of palletizing robots. The automation of palletizing robots mainly includes automatic control and automatic detection.

The requirement of intelligence is to realize the effective combination between the operator and the equipment, that is, the integration of man and machine, and the automated system simulates the human brain for operation and control, so that the work that needs to be done manually, such as sorting and searching data, is handed over to the machine. Completion not only improves the accuracy and efficiency, but also reduces labor costs and greatly reduces the work intensity of technicians.

2)High speed

It is not only necessary to promote the high speed of the stand-alone machine, but also to improve the high speed of the palletizing system. On the premise of continuously improving the degree of automation, the structure of the palletizing robot is continuously improved. At the same time, attention should be paid to the production efficiency of the entire palletizing system, so that the high-speed development can be developed to a deeper level.

3)Adopt modular structure

Modularization is also one of the future development trends of palletizing robot manufacturing automation. Compared with the traditional production mode of the palletizing robot industry, the modular production and integrated development model can greatly accelerate the technological progress of the palletizing robot industry, improve product production efficiency, reduce production costs, and enhance corporate competitiveness.

4)Multifunctional palletizing robot

For the production of high-volume, fixed-size products, there are generally corresponding equipment for palletizing. However, in recent years, with the continuous growth of the multi-variety, small-batch, and customized product market, as well as the sharp increase in users of small and medium-sized enterprises, the application prospects of multi-functional general-purpose palletizing robots are very broad.