Bending follower is the common additional configuration used on the cnc hydraulic press brake. Shenchong press brake bending follower is more flexible than the traditional sheet follower, which can not only be used on CNC press brake, but also be connected with NC press brake. This article teach customers how to quickly install SHENCHONG bending follower by themselves.

Before bending follower instalation, first to put the sheet follower in front of the press brake machine, and adjust the bottom wheels and four movable bolts of the bending follower to ensure that the follower table and the hydraulic press brake lower die plane are flush. The distance between sheet follower table and the press brake lower die distance is about 6cm from the bending machine, and will continue to be fine-tuned in the follow-up.

Under normal condition, install the magnetic scale next to the press brake magnetic scale. If there is no place to install it to the side of the press brake slider, you can process a piece of metal sheet as shown in the video for installation. Punch holes at both ends of the iron sheet to fix the bending follower magnetic scale to the slider of press brake. After installation, it is necessary to step on the bending machine to the bottom dead center position, and adjust the origin target position of the sheet follower magnetic scale to about 20mm below the middle position of the sheet follower magnetic scale identification module.

There are magnetic scale six signal line: A+, A-, B+, B-, Z+, Z-, and two power lines of the magnetic scale. Press brake bending follower device power line: 1:220V, 1 phase line, 1 neutral line, 1 ground line. 2:380V, 3 phase wires, 1 neutral wire and 1 ground wire. The grounding wire is better to be parallel connected in parallel with the press brake electrical cabinet grounding point.

The slow down speed of the hydraulic press brake cannot exceed 0.6 meter/min

Turn on the press brake follow-up device power supply (PLC right side), turn on the emergency stop switch (left side), and the upper right SON on the screen turns red. First take a sheet plate to test the 180 degree bending on the press brake machine (follow-up device does not start) to observe whether the upper punch tip just touches the plate when the punch reaches the bottom dead center. If it is not necessary to adjust the parameters of the press brake machine firstly, the subsequent operation should ensure the accuracy of the press brake.

Click "forward rotation" on the sheet follower PLC manual page (at this time, the follower moves slightly upwards), and then click "back to origin", at this time, the "origin" in the upper right corner turns red.

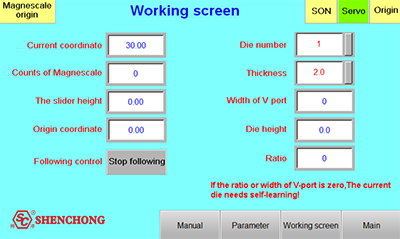

Let the press brake machine run back and forth (up and down) without bending plate, and in the "Working Screen" or "Parameter Settings", you can see that the "Magnetic Scale Origin" in the upper left corner turns red.

In the "parameter setting" page, the magnetic scale shows a value at this time (assuming the value is 200), click the "magnetic scale origin" in the upper left corner to turn yellow, let the press brake ram run up and down one back and forth, "magnetic scale origin" turns red and the slider height shows a value (let's say 260). At this time, measure the actual value of the height of the slider (the actual value is the distance between the quick clamp bottom and the die holder upper surface. The upper die force point and the lower die lower plane can be judged by the height of the upper and lower die in the CNC press brake controller, or consult our company after sales department). Assuming that the actual measurement value is 300, then the "magnetic scale origin" should be revised as : 200+(300-260)=240. After revising, click "Magnetic Scale Origin" to turn yellow, and then run the press brake machine for a back and forth. At this time, the value of "Slider Height" in the animation screen becomes 300.

At this time, the origin of the magnetic scale has been initially found, and subsequent fine-tuning will continue.

Go to the "parameter setting" screen, input the press brake tooling number, Vee width, plate thickness, lower die height and upper punch height.

Find a sheet metal plate, bend it 90 degrees and hold it still (you can adjust the pressure holding time of the press brake to 5 seconds), and enter the displayed value of the "magnetic scale" at the "bottom dead center" .

Press the positive rotation button and let the bending follower work surface and the pressed board to fit completely. (At this time, the front and rear positions of the bending follower table can be fine-tuned, and the adjustment way is to turn the hand-wheel in front of the bending follower or the electric knob on the side). Click "Learn to Start", a "speed ratio" will be generated at this time, and check the "Mold Parameters" to ensure the speed ratio is written, click "Learning Stop" after the writing is successful, and bending follower table return to the initial position, and the learning is completed.

Click "Working Screen" page and click "Start Follow", and set the bending angle of the press brake machine to 178 degrees. If the bending follower action is too large or the bending follower table does not move, you need to modify the value of "Magnetic Scale Origin".

Before modifying, click "Start follower" to turn gray (exit follow mode). Enter "parameter setting", if the follower action is too large, "magnetic scale origin" should be increased, otherwise, it should be decreased. During the adjustment, the value of each modification is generally controlled at 0.1-0.2. After modifying the value, click "Magnetic Scale Origin" in the upper left corner to turn yellow. Run the hydraulic press brake machine back and forth, and the "magnetic scale origin" turns red. Repeat step 7.

Under the condition that the 178 degree bending follower action is normal, you can repeat step 5 to learn the 90 degree bending follow-up of the plate. If the origin of the magnetic scale is changed, it must be re-learned. After the learning is completed, you can go to the "work screen" to start the follow-up bending. To learn a new board, repeat steps 4, 5, and 6.

Wuxi Shenchong Forging Machine Co.,Ltd has press brake bending sheet follower, hybrid servo press brake, tandem press brake and CNC press brake for sale. If you have any question or need our quotation, please feel free to contact with us.

The Best Price: 5,000 USD