Automatic bending center focuses on solving various complex sheet metal and bending problems in metal forming industry. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is solved from a technical point of view, effectively improving production efficiency and reducing production costs. Currently China automatic panel bender machine with lower price and high quality become more and more popular in the global market.

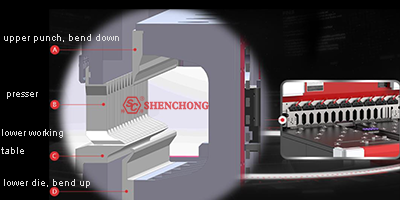

The main working principle of the automatic bending center is as follows:

1. The plate is placed flat on the working table of the cnc flexible panel bender machine, and the position is designated by the backgauge rear stopper. After the edge holder beam tool presses the plate, the edge holder beam tool realizes the upward and downward bending action.

2. The flexible bending center is mainly composed of four parts: the back gauge table, the edge blanking beam, the bottom beam and the edge folding beam.

The multilateral bending center adopts a universal bending die, which can automatically adapt to various geometric shapes and realize mass production. This enables it to combine high performance, automatic bending and handling with gentleness.

For companies that require foam processing (such as refrigerators, rice steamers, etc.), the part consistency provided by the multilateral automatic bending center makes the parts no longer need to clean up the leaking bubbles, and the processing efficiency and product quality are improved.

The suction cup lifting device of the multilateral cnc panel bender machine, one of the four sides of the bending is folded down, and the last fold can be lifted out. If the surface requirements are high, it can be lifted and fed for processing, so as to avoid the friction marks caused by the friction between the workpiece and the brush.

In the process of bending large panels by the multilateral bending center, there is no need to manually lift the plate, which avoids the back-folding caused by the incomplete lifting of the plate, the surface quality is improved, and the production efficiency is also greatly improved compared with the use of a bending machine, with an average increase of more than 40%; highly flexible processing, can meet the production of small batches and many varieties.

1. Large plates: plates exceeding 2 meters or those that are difficult to locate and ensure accuracy for single-person bending.

2. heavy plate: more than 30 kg.

3. No damage is required on the surface: pre-coated plate, stainless steel, aluminum plate, etc.

4. High dimensional and angular accuracy requirements: meet the subsequent welding accuracy requirements.

5. Multi-variety and small batches use a general-purpose tool to complete all processes in one machine.

6. Arc bending, what you draw is what you get.

7. Need to meet the JIT production mode.

8. Product quality: the boss does not need hire experienced bending operator.

1. The difference between folding and bending principles.

2. The benchmarks of the expansion diagrams are different.

3. Different bending dimensional accuracy.

4. Bending angle accuracy is different.

5. The problem of scratches and damages on the surface of the material.

6. Requirements for the technical level of workers.

7. Tool configuration.

8. Tool life.

9. Operation position.

10. The drive system is different.

Some customers would confused about the difference between cnc press brake and automatic panel bender machine. Although these two kinds plate bending machine has some similar bending application, CNC press brake machine is better for thick and wide side bending, and automatic bending center is for narrow side bending. We will discuss more about the differences in the next article.