Sheet metal processing are parts made by a comprehensive cold working process for thin metal plates (usually less than 6mm), including shearing, punching, cutting, bending, welding, riveting, splicing, forming, etc.

The material commonly used in sheet metal processing technology are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (brass, red copper, beryllium copper), aluminum sheet (6061, 5052, 1010, 1060, 6063, duralumin, etc.), stainless steel (mirror, brushed, matte), etc. According to the different functions of the product, the materials used are different. Generally, the use and cost of the product should be considered.

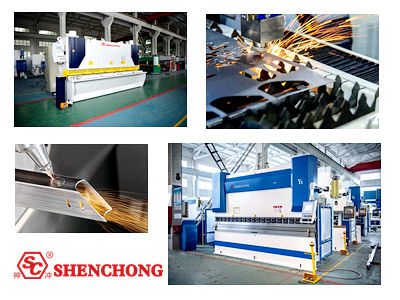

The process method of sheet metal processing through digital punching, laser cutting, shearing machine, bending machine, riveting machine and other equipment, generally used for sample production or small batch production, the cost is high. The processing cycle is short and the response is fast.

The sheet metal is processed through a fixed mold. Generally, there are blanking molds and forming molds, which are mainly used for mass production and have low cost. The initial mold cost is high, and the quality of the parts is guaranteed. The pre-processing cycle is long and the mold cost is high.

- Uniform thickness. For a part, the thickness of all parts is the same

- Light weight, high strength, electrical conductivity, low cost, good mass production performance.

The equipment of the shearing process is a shearing machine, which can cut a metal sheet into a basic shape.

Advantages: low processing cost.

Disadvantages: average precision, cutting with burrs, and a single cutting shape is a simple rectangle or other simple straight lines. composed of graphics.

Before the shearing process, the unfolded size of the part must be calculated. The size of the unfolded size is related to the bending radius, bending angle, sheet material and sheet thickness.

SHENCHONG guillotine shearing machine provides high strength, productivity, sensitivity, and safety while lowering your production cost and improving your bottom line. Kindly contact us for any new need.

The equipment of the punching process is a punching machine, which can further process and shape the cut material. Punching various shapes requires different dies. Common dies include round holes, oblong holes, and bosses. There are many kinds of bosses, including cooling holes, mounting holes, etc. Due to the influence of bending, the edge of the design hole is limited from the edge of the sheet and the edge of the bend. For the boss, it should be noted that the height of the boss is limited, which is related to the material of the plate, the thickness of the plate, and the angle of the slope of the boss.

For materials that cannot be removed by shearing and punching processes, or plates with high hardness that can easily damage the mold, such as rounded corners, or when there is no ready-made mold to stamp the required shape, laser cutting can be used to complete the forming of the material and then proceed to the next bending work.

Advantages: cutting without burrs, high precision, can cut any graphics, such as leaves, flowers, etc.

Disadvantages: high process cost.

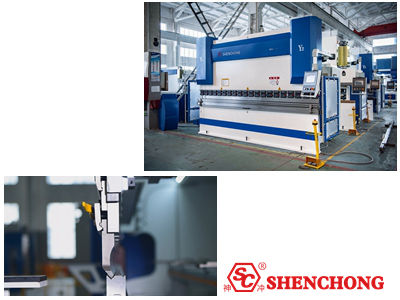

They can fold or roll the metal sheet into the desired shape, which is the forming process of the parts; the process of cold pressing the metal sheet through the upper and lower knives of the bending machine to obtain the desired shape is called bending.

Bending restrictions:

Most press brakes have certain restrictions on bending.

Unilateral height:

Depends on the size of the bending machine and the height of the upper tool, the solution can be multi-sided and large-angle bending.

Bilateral height:

Not greater than the maximum height of one side, in addition to all restrictions on the height of one side, but also limited by the bottom side: bending height < bottom side.

SHENCHONG offers all kinds of sheet metal processing equipment including CNC press brake with provided high quality and best service for all customers who need professional technology for improving their production efficiency and lower down their production cost.

Commonly used welding in sheet metal processing includes arc welding and resistance welding.

- Arc welding

There should be enough welding space between the sheet metal, the maximum welding gap should be 0.5 ~ 0.8mm, and the welding seam should be uniform and flat.

- Resistance welding

The welding surface should be flat, without wrinkles, springback, etc. Resistance welding spot spacing: When welding large-sized parts, the spot spacing can be appropriately increased, generally not less than 40-50mm. For non-stressed parts, the welding spot spacing can be enlarged to 70-80mm.

The treatment of sheet metal surfaces can play a role in corrosion protection and decoration. Common surface treatments of sheet metal include: powder coating, electro-galvanizing, hot-dip galvanizing, surface oxidation, surface drawing, screen printing, etc.

- Powder coating

The surface of sheet metal is sprayed with liquid and powder paint. We usually use powder paint. Through powder spraying, electrostatic adsorption, high temperature baking, etc., a layer of paint of various colors is sprayed on the surface of the sheet metal to beautify the appearance and increase the corrosion resistance of the material. It is a commonly used surface treatment method.

- Galvanizing

Galvanizing on the surface of sheet metal is a common surface anti-corrosion treatment method, and can play a certain role in beautifying the appearance. Galvanizing can be divided into electro-galvanizing and hot-dip galvanizing.

The appearance of electrogalvanizing is relatively bright and flat, and the galvanized layer is thinner, which is more commonly used.

The galvanized layer of hot-dip galvanizing is thicker, and can produce an iron-zinc alloy layer, which has stronger corrosion resistance than electro-galvanizing.

- Surface oxidation

An anodized film is produced on the surface of the material, which has high hardness and wear resistance, as well as good electrical insulation and thermal insulation.

- Surface drawing

Put the material between the upper and lower rollers of the wire drawing machine. The roller is attached with an abrasive belt, which is driven by the motor to let the material pass through the upper and lower abrasive belts, and pull out traces on the surface of the material. According to the different abrasive belts, The thickness of the traces is also different, and the main function is to beautify the appearance. Generally, the surface treatment method of brushing is considered only for aluminum materials.

- Screen printing:

The process of screen printing various logos on the surface of the material. Generally, there are two methods: flat screen printing and pad printing. Flat screen printing is mainly used on general planes, but if there are deep pits, it needs to be used. pad printing.