An manipulator automatic loading and unloading is an automatic operating device that can mimic certain movement functions of human hands and arms, used to grasp, transport objects or operate tools according to a fixed program.

The characteristic is that various expected tasks can be completed through programming, which combines the advantages of both human and mechanical devices in terms of construction and performance. It can replace the heavy labor of humans to achieve mechanization and automation of production, and can operate in harmful environments to protect personal safety.

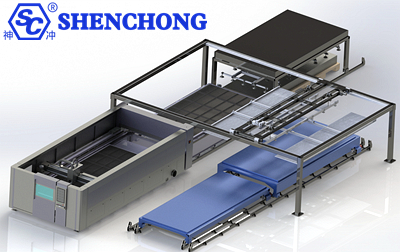

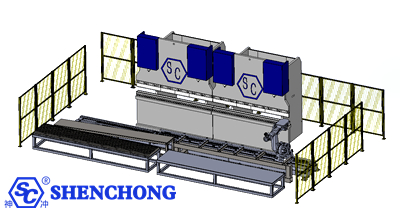

Compared to manual loading and unloading, the manipulator automatic sheet metal loading and unloading can more quickly and efficiently complete the loading and unloading work in the processing production line, which is increasingly favored by customers in the sheet metal processing industry. The sheet metal loading and unloading manipulator is suitable for various types of CNC machining centers, press brake, shearing machines and other automated equipment. The application scenarios include fields such as automobiles, electronics, machinery, household appliances, and construction, which have become a new choice for intelligent and automated production due to their efficient and intelligent characteristics.

The hand is installed in the inner hole of the front end of the arm and is equipped with a transmission shaft, which can transmit the application to the wrist for rotation, bending of the wrist, and opening and closing of fingers. The structure of the automatic loading and unloading robot arm imitates human fingers and is divided into three types: articulated, fixed, and free joints. The number of fingers can be divided into two fingers, three fingers, four fingers, etc., with two fingers being the most commonly used. Multiple shapes and sizes of chucks can be equipped according to the shape and size of the clamped object to meet the needs of operation. The so-called hands without fingers generally refer to vacuum suction cups or magnetic suction cups.

The function of the arm is to guide the fingers to accurately grasp the workpiece and transport it to the desired position. In order for the automatic loading and unloading manipulator to work correctly, all three degrees of freedom of the arm need to be accurately positioned.

The torso is a bracket for installing arms, power sources, and various actuators.

The hydraulic driven automatic loading and unloading manipulator is usually composed of a hydraulic motor (various oil cylinders, oil motors), servo valves, oil pumps, oil tanks, etc., forming a driving system, which is operated by the actuator of the loading and unloading manipulator. Usually, it has great gripping capacity (up to several hundred kilograms or more), characterized by compact structure, smooth operation, impact resistance, vibration resistance, and good explosion-proof performance. However, hydraulic components require high manufacturing accuracy and sealing performance, otherwise oil leakage will pollute the environment.

The pneumatic drive system is usually composed of cylinders, valves, cylinders, and air compressors, which are characterized by convenient air supply, rapid action, simple structure, low cost, and convenient maintenance. But it is difficult to control the speed, and the air pressure should not be too high, so the gripping ability is relatively low.

Electric drive is the most commonly used driving method for automatic loading and unloading robotic arms. Its characteristics are convenient power supply, fast response, large driving force (the weight of the joint type has reached 400kg), convenient signal detection, transmission, and processing, and multiple flexible control schemes can be adopted. The driving motor generally adopts a stepper motor, with DC servo motor (AC) as the main driving method. Due to the high speed of the motor, a reduction mechanism (such as harmonic drive, RV cycloidal pinwheel drive, gear drive, screw drive, and multi bar mechanism) is usually required. Some automatic loading and unloading robotic arms have begun to use high torque, low speed motors without deceleration mechanisms for direct drive (DD), which can simplify the mechanism and improve control accuracy.

Mechanical drive is only used in situations where the action is fixed. Generally, cam linkage mechanisms are used to achieve specified actions. Its characteristics are reliable action, high working speed, low cost, but not easy to adjust. Others also use hybrid drive, namely liquid gas or electro-hydraulic hybrid drive.

The control of manipulator automatic loading and unloading is divided into two types: point control and continuous trajectory control. The control system can be designed using numerical sequential control according to the requirements of the action. It first needs to develop a program for storage, and then according to the prescribed program, control the automatic loading and unloading manipulator to store the work program in two ways: separate storage and centralized storage. Separate storage refers to storing information on various control factors separately in two or more storage devices, such as sequential information stored in pin plates, cam drums, and perforated belts; Location information is stored in time relays, fixed speed rotary drums, etc; Centralized storage refers to storing all information related to various control factors in a storage device, such as magnetic tapes, drums, etc. This method is suitable for situations where sequence, position, time, speed, etc. must be controlled simultaneously, that is, when used in continuous control.

The pin board is used in situations where rapid program changes are required. Changing a program only requires replacing one type of plug board, which is Cocoa, and the same plugin can be used repeatedly; The program length that can be accommodated by the perforated tape is not limited, but if an error occurs, all programs must be replaced; The information capacity of perforated cards is limited, but they are easy to replace and store, and can be reused; Magnetic cores and drums are only suitable for situations with large storage capacity. As for which control component to choose, it is determined based on the complex and precise program of the action. For complex automatic loading and unloading robotic arms, a teaching and reproducing control system is adopted. More complex automatic loading and unloading robotic arms are controlled by digital control systems, small computers, or microprocessors. The most commonly used control system is the pin plate, followed by the cam drum. It is equipped with many cams, each assigned to a motion axis, and the drum completes a cycle in one revolution.

Firstly, the manipulator needs to detect the position and size of the sheet metal through sensors. Sensors can detect the position and size of the sheet metal, allowing the manipulator to accurately grasp the sheet metal.

The manipulator accurately grasps the sheet metal based on the signal from the sensor, and then moves the sheet metal to the cutting machine to complete the automatic loading of the sheet metal.

After receiving the sheet metal, the cutting machine automatically cuts it. The cutting machine can automatically complete the cutting, punching, bending and other processes of sheet metal according to the preset program, thereby achieving automated production.

After the cutting is completed, the manipulator needs to move the sheet metal back to its original position and grab the cut parts. The manipulator can automatically complete the cutting of sheet metal and the gripping of parts according to the preset program.

The manipulator can continuously repeat the above operations according to the preset program, achieving automated loading and unloading of sheet metal and automated production of parts. Due to the high speed, efficiency, and precision of robotic arms, they can greatly improve production efficiency and product quality, and reduce labor costs.

The manipulator automatic loading and unloading can perform high-speed, efficient, and precise operations, greatly improving production efficiency and reducing production costs.

The manipulator automatic loading and unloading can replace manual labor to complete repetitive and tedious tasks, reducing labor costs and improving production efficiency.

The manipulator automatic loading and unloading perform precise operations, ensuring the stability and reliability of product quality, and enhancing the market competitiveness of the product.

The manipulator automatic loading and unloading can replace manual labor in dangerous, high-temperature, high-pressure and other operations, which can improve production safety and work environment comfort.

In short, the manipulator can achieve automatic loading and unloading of sheet metal, greatly improving production efficiency and product quality, reducing labor costs, and improving production safety and working environment comfort. With the continuous development of manufacturing and the expansion of applications, manipulator will be widely used in more fields.

The sheet metal loading and unloading manipulator requires regular maintenance and upkeep, and cleaning, lubrication, and replacement of worn parts are essential. At the same time, when using the sheet metal loading and unloading manipulator, workers should follow the operating procedures, regularly inspect the electronic control system and transmission system of the machine, and avoid losses and accidents caused by human factors.

In summary, the application of manipulator automatic loading and unloading will provide efficient, intelligent, and accurate production solutions for the sheet metal processing industry, making the processing production line intelligent and automated, and helping enterprises develop rapidly.