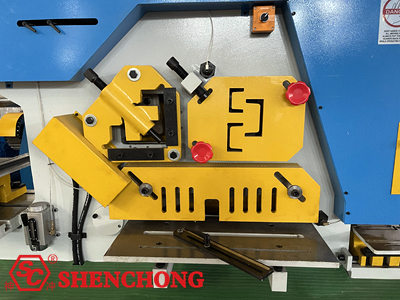

The Multifunctional Hydraulic Ironworker Machine is a processing equipment used for shearing, die cutting and punching metal profiles. It is widely used in punching and shearing of commonly used metal materials. For example, punching and shearing of common metal profiles such as diagonal steel, channel steel, square steel, etc.

The application of multi function ironworker machines makes punching and shearing of metal profiles simple. In addition to following the correct method during daily use, we should also pay attention to the related maintenance of the equipment. At the same time, we should also pay attention to some safety matters during use, so that we can skillfully punch and shear metal profiles.

Check the power supply before using the combined punching and shearing machine. The power supply is stable, there is no phase loss, and the leakage protector and air switch are intact. To connect the wiring, open the equipment wiring cabinet, connect the wiring and close the cabinet door.

After powering on, step on the foot switch. If the machine does not move, swap the power cords and check whether the emergency stop light is turned on.

The lubricating oil of each transmission part should be sufficient. It is better to refuel each lubrication point 2-3 times per shift. The shearing tools and punching dies should be intact without cracking and fastened firmly.

The hydraulic ironworker machine is electrically insulated and well grounded.

Every time the tool is changed, the mold needs to press the emergency stop button and turn off the power. Please switch to inching mode when debugging punches, dies, and blades, and switch to single-action mode for normal operation.

The gap between the upper punch and the lower die hole wall in the punching station is uniform, which meets the stamping requirements. The minimum formation of the upper punch (mold edge) should slightly exceed the plane of the lower die hole (mold edge).

The lowest formation of the upper knife edge at the shearing station is also slightly beyond the plane of the lower knife edge.

After the work is completed, turn off the main power switch, unplug the power cord, and clean up any debris.

As an industrial facility, hydraulic punching and shearing ironworker machines have certain risks. Therefore, operators must strictly follow the mechanical safety operating procedures. Before operating, you must be familiar with the structure and performance of the machine tool, and you must be trained and qualified before you can start operating.

- Before use, check whether all parts of the machine are intact and whether the wire connectors are secure.

- The weight and die must be assembled correctly and cannot be easily replaced or adjusted.

- Keep all edges sharp.

- During operation, the multifunctional hydraulic ironworker machine should be kept dry and clean. Prevent dust, debris, etc. from entering the inside of the machine.

- Punching and profile cutting cannot be performed at the same time.

- There must be no weld scars or protruding burrs on the surface of the sheared and punched sheets.

- Don't overwork.

- It is prohibited to walk around in front of the combined punching and shearing machine to prevent accidents such as being scratched, bumped, or strangled by the machine.

- Operators must wear work clothes and necessary protective equipment.

- When performing tool replacement, maintenance, etc., the operator must unplug the power plug to ensure that the ironworker machine power is cut off.

- In order to ensure the safety of punching and shearing, the workpiece pressing mechanism must be adjusted accordingly according to different specifications.

- If the tool is replaced, the blade clearance must be rechecked. Timely adjustments need to be made when necessary.

- Regularly check the connection status of each machine part. If there is any abnormality, stop using it and repair it immediately.

- Fill each lubrication point with oil according to the length of working time to avoid damage to the friction surface.

- After each use, the machine should be cleaned and lubricated.

- Pay attention to the operation of the machine. Deal with failures caused by damage such as burning, breakage, etc. in a timely manner.

- Regularly check whether the various components and circuits of the machine are loose or falling off. Perform maintenance in a timely manner.

- Do not use the combined punching and shearing machine for a long time. Idling should be carried out at regular intervals to ensure the normal operation of the machine.

The combined punching and shearing machine can be turned on but cannot be operated. It is likely that there is a problem with some components or control circuits. The machine should be shut down for troubleshooting.

The machine works but doesn't work well. If the weight is uneven or the mold is worn, it needs to be adjusted or replaced.

When the machine failure is a circuit problem, professional electricians should be asked to investigate. Do not disassemble components at will to avoid causing greater losses.

The multifunctional ironworker punching and shearing machine integrates multiple functions such as punching, plate shearing, angle steel cutting, and profile cutting. It has multiple advantages such as multi-station, light weight, small size, low noise, high efficiency, low investment, high efficiency and complete functions. It is an ideal processing equipment for modern machinery manufacturing industries such as metallurgy, bridges, communications, and electric power.

Only by ensuring the safe operation and daily maintenance of the multifunctional hydraulic ironworker machine and promptly eliminating hidden dangers during troubleshooting can the service life and stability of the machine be effectively improved.