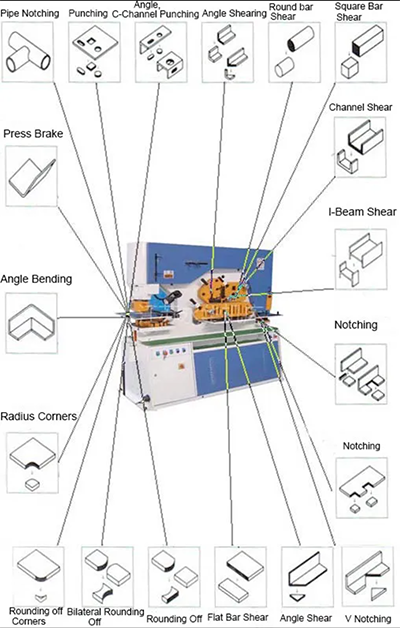

Hydraulic ironworker machine is probably the most versatile tool in any fabrication or welding shop because it is more than just a machine and is often referred to as the "Swiss Army Knife" of the fabrication industry.

With stations for punching, notching, shearing and more, hydraulic ironworkers should be an integral part of your metal fabrication operation. When processing small workpieces, it can replace the functions of various large machines such as punch presses, plate shearing machines, and bending machines to saving you equipment investment. Hydraulic ironworker machine saves labor, time, energy and costs.

Intelligent Manufacturing Redefine Your Future!

SHENCHONG Q35Y hydraulic ironworker adopts hydraulic driving system and it is the latest iron workers in the market, various metal plate, square bar, round bar, angle, channel and joist can be cut, punched and notched on the machine. It is also equipped with a stop device for cutting.

Hydraulic ironworker machine from China for sale.

Also welcome to check with our related products:

Double cylinders hydraulic punch & shear machine

More productivity with adjustable piston stroke distance

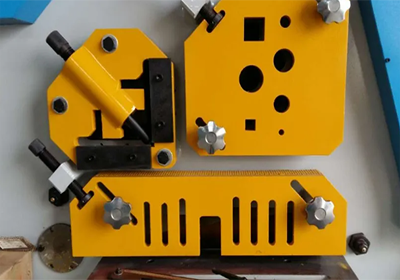

Large punch table with multi-purpose bolster

Removable table block for overhang channel / joist flange punching applications

Universal die bolster, easy change punch holder fitted, punch adapters supplied

Angle, round & square solid monoblock crop station

Central lubrication system

Electrical back gauge

Working light

Safety movable foot pedal

Electric panel with overload protection elements and ingratiated controls

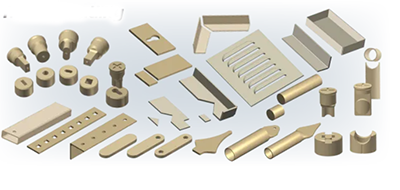

1. Ø26 mm punch and die and standard punching tools

2. Steel solid round and square bar cutting blade set

3. Angle cutting blade set

4. Sheet metal cutting shear

5. U-Notching blade set

Solid Stock , Flat Bar and Angle Shearing Stations.

Punching station

Rectangle Notching Station

Mould Tooling and Samples.

Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 |

Pressure(Ton) | 66 | 90 | 120 | 165 |

Max.Cutting Thickness(mm) | 16 | 20 | 25 | 30 |

Plate Strength(N/mm^2) | ≤450 | ≤450 | ≤450 | ≤450 |

Cutting Angle(degree) | 7° | 8° | 8° | 8° |

Shearing Size of One Stroke(mm) | 16x250 8x400 | 20x330 10x480 | 25x330 16x600 | 30x355 20x600 |

Ram Stroke(mm) | 80 | 80 | 80 | 80 |

Cycles/min(20mm stroke) | 28 | 28 | 26 | 27 |

Throat Depth(mm) | 300 | 355 | 400 | 600 |

Punching Thickness(mm) | 16 | 20 | 25 | 26 |

Max.Punching Dia.(mm) | 25 | 30 | 35 | 38 |

Power of Main Motor(Kw) | 4 | 5.5 | 7.5 | 11 |

Overall Dimensions LxWxH(mm) | 1640x730x1770 | 1860x800x1900 | 2355x960x2090 | 2680x1040x2300 |

Weight of Machine(kg) | 1600 | 2000 | 4800 | 6800 |

Q: How to get a high quality hydraulic ironworker quotation from SHENCHONG?

A: Every customer can get hydraulic ironworker price from us. contact with us now and get the quotation.

Q: Do you offer teaching & training?

A: Yes. As a professional hydraulic ironworker factory, we provide detailed machine user manuals and train videos, or customers can set a video call with our sales and engineers. Or we can send our engineers to your company to train you.

Q: What is the shipping cost from China to your country?

A: We can send hydraulic ironworkers to your port or door address by sea or rail. Please kindly tell us your nearest port. We have reliable shipping agent to insure the safe convenient and time delivery.

Q: Do you accept LC payment?

A: Yes, normally our payment is 30%+70% T/T, LC payment is also acceptable. Our hydraulic ironworker price for sale is affordable, contact with us today!