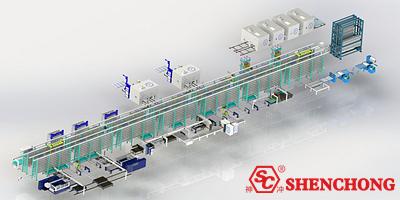

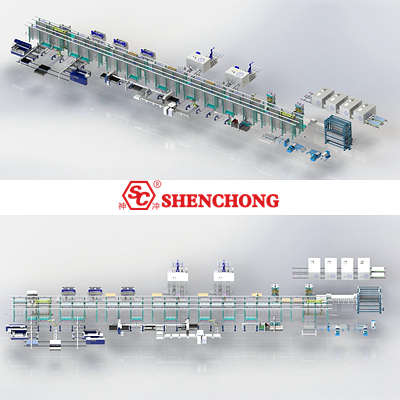

Automated production lines are the development trend of modern manufacturing industry. Automatic sheet metal production lines are an efficient, precise, and reliable production method that has been widely applied in various fields.

With the continuous development of intelligent technology, adopting automated facilities without manual intervention is the most effective measure to improve labor productivity and economic benefits. Enterprises can quickly and effectively improve production efficiency, stabilize product quality, and save personnel costs through automated production lines. So, how should companies plan for automated production? What conditions should be met?

Automatic production lines have become the mainstream of modern industrial production, and more and more manufacturers are using automated production lines to improve production efficiency and product quality. However, to use automated production lines, manufacturers need to have certain conditions.

The auto production line requires a large amount of investment, including equipment, technology, and human resources. Therefore, manufacturers need to have a certain level of financial strength to support the construction and operation of production lines.

Automated production lines require technologies that involve multiple fields, including mechanical, electronic, computer, and other technologies. Therefore, manufacturers need to have a certain level of technical strength in order to proficiently master the technology and operation of flexible lines.

The automated production line requires complex production management and control. Only with a certain level of management strength can we ensure the efficiency and quality of production. Therefore, manufacturers need to have certain management capabilities, including production management, quality management, safety management, and other aspects.

The automatic production line needs to be produced and adjusted according to market demand. If the market demand is insufficient, the investment and operation of auto-production lines will face difficulties. Therefore, manufacturers need to have a certain market demand in order to ensure the feasibility of the investment and operation of the whole lines.

In short, manufacturers using automated production lines need to have certain conditions in terms of funding, technology, management, and market demand in order to achieve the efficiency and quality.

Click here to know: Application And Advantages Of Truss Robot For Sheet Metal Processing

Automatic sheet metal production line is the inevitable trend of modern industrial development, and many enterprises have begun to pay attention to how to design their own automatic production line.

Here are some suggestions:

Different enterprises have different products, processes and output requirements. Therefore, it is necessary to design according to its own characteristics. In the design stage, experts in sheet metal industry or consulting sheet metal machine manufacturers can be invited to provide technical support to ensure the efficient operation of the production line.

Automatic production line needs all kinds of equipment and technology to realize automatic production, and there are many choices in the market. Enterprises need to choose suitable equipment and technology according to their own production needs and budgets, and consider its stability, reliability and maintenance costs.

The complexity of the production process will directly affect the production efficiency and cost. Therefore, enterprises should simplify the operation steps as much as possible and adopt some automatic control technologies to improve production efficiency.

Automated production lines need certain technicians to maintain and monitor the operation of equipment. Enterprises need to train workers, improve their technical level and quality, and establish a perfect monitoring system to find and solve problems in time.

To sum up, designing an automated production line that suits you needs enterprises to understand their own needs and goals, choose appropriate equipment and technology, optimize production processes and establish a sound monitoring system. Then, choose a trusted automation equipment manufacturer or design expert. Through reasonable design and good management, enterprises can realize the efficient operation of automated production lines, improve production efficiency and reduce costs.