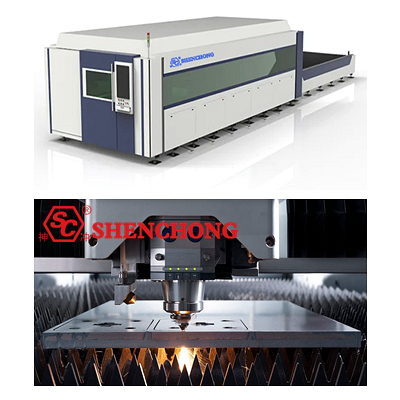

With the development of industry, laser cutting technology has become increasingly favored by people. Due to the advantages of high efficiency, energy conservation, fast precision, and strong stability, sheet metal laser cutters have been widely used in industries such as aerospace, automotive manufacturing, shipbuilding, food processing, medical beauty, jewelry, and electronic component manufacturing.

Sheet metal laser cutting machines have a wide use, including many industries. And it is one of the essential equipment for many enterprises.

For example:

Advertising sign production: these are mainly stainless steel logos and logo cutting.

Metal material production: basically including all metal materials. These are generally mainly raw materials for bending and polishing work pieces. Cutting is one of the most important processes.

Cabinet production: Generally made of carbon steel or stainless steel. It mainly involves the connection of bending process flow

There are also various aspects such as subway parts, elevator casings, mechanical equipment casings, kitchen utensils, and so on.

Laser cutting machine is a technological revolution in sheet metal processing. Laser cutting machines have a high degree of flexibility. Fast cutting speed. High production efficiency. The production cycle of the product is short. We have won a wide market for our customers.

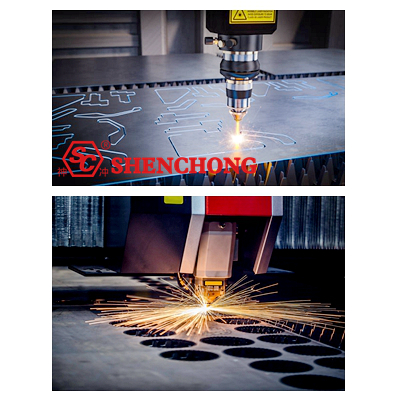

Generally speaking, it is recommended to use laser cutting machines to cut metal materials such as carbon steel plates within 12mm and stainless steel plates within 10mm.

The laser cutting machine is stress free. Processing without deformation. No tool wear. Good material adaptability. Both simple and complex parts can be cut by laser precision rapid prototyping at one time. Its cutting seam is narrow.

Good cutting quality. High degree of automation. Easy to operate. Low labor intensity. No pollution. It can achieve automatic cutting layout, nesting, and improve material utilization. Low production cost and good economic benefits.

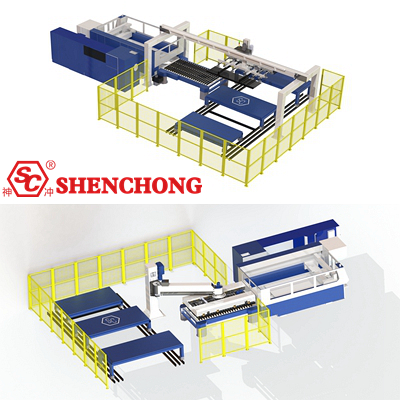

There are many factors to consider when choosing a CNC sheet metal laser cutters. In addition to considering the maximum size, material, maximum thickness to be cut, and the size of the raw material format of the currently processed work piece, more attention needs to be paid to the future development direction. For example, the maximum workpiece size to be processed after the technical modification of the product, the width of the materials provided by the steel market, which type of product is the most cost-effective for oneself, and the loading and unloading time, etc.

Firstly, Understand you own cutting needs

Factory self use or outsourced processing? What material is cut? What is the thickness? The thickness that is frequently cut? What is the thickest cutting thickness? These should be summarized in advance.

Select the appropriate power range according to the cutting needs. Merchants who purchase equipment must consider the cost. Choose the most suitable laser cutting machine for yourself in terms of budget funding.

Second: Confirm the cutting speed

Another important factor in determining whether a laser cutting machine is excellent is cutting speed. Cutting speed provides users with a more intuitive effect.

The faster the production efficiency, the higher the cutting speed and laser power. The optimal cutting speed has a significant impact on the cutting quality, notch width, and roughness.

Thirdly, can relevant services be provided in a timely manner

Sheet metal CNC laser cutter not only purchase equipment quality and service, but also pay attention to whether the brand has after-sales support. When purchasing, it is also important to pay attention to pre-sales testing and ensure that any equipment malfunction or force majeure can be immediately resolved through after-sales service.

Laser Cutting Automatic Production Line

To choose a suitable laser cutting machine, the first consideration should be whether the performance indicators of the equipment itself meet the requirements. Then,you should pay attention to selecting product types that match the scope of use. Finally, it is necessary to do a good job in daily maintenance and upkeep to ensure the normal operation of the equipment in order to fully leverage its advantages.