In today's highly competitive market, choosing a suitable CNC machining center is crucial for enterprises. CNC machining center is a CNC machining machine with comprehensive functions. It combines milling, boring, drilling, tapping and thread cutting functions on one device, making it have multiple process means.

The application of CNC processing technology has penetrated into various industries. Therefore, choosing an excellent CNC machine manufacturer has become a key decision in the process of enterprise development.

The machining center is developed from a CNC milling machine. The biggest difference from a CNC milling machine is that the machining center has the ability to automatically exchange machining tools. By installing tools for different purposes on the tool magazine, the machining tools on the spindle can be changed through the automatic tool changer in one clamping to achieve multiple machining functions.

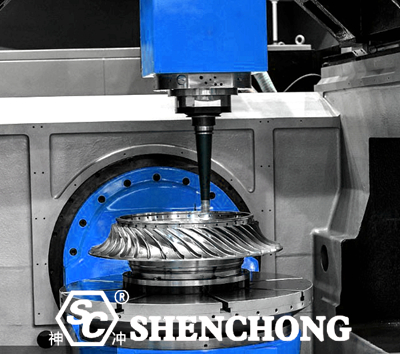

The CNC machining center is a high-efficiency automated machine tool suitable for machining complex parts composed of mechanical equipment and CNC systems. The CNC machining center is one of the most productive and widely used CNC machine tools in the world.

It has a strong comprehensive machining capability, and can complete more machining content after the workpiece is clamped once. The machining accuracy is high. For batch workpieces with medium machining difficulty, its efficiency is 5 to 10 times that of ordinary equipment. In particular, it can complete many processes that ordinary equipment cannot complete. It is more suitable for single-piece machining with complex shapes and high precision requirements or small and medium-sized batch multi-variety production.

- According to the spatial position of the spindle during processing, the machining center can be classified into: horizontal and vertical machining centers.

- According to the process use, there are: boring and milling machining centers, compound machining centers.

- According to the special functions, there are: single-table, double-table and multi-table machining centers. Single-axis, double-axis, three-axis and replaceable spindle box machining centers.

- According to the guide rail classification, there are: linear rail machining centers, hard rail machining centers, etc.

CNC machining center is a CNC machining machine with more complete functions. It concentrates milling, boring, drilling, tapping and thread cutting functions on one device, so that it has a variety of process means.

The machining center is equipped with a tool magazine. The tool magazine stores different quantities of various tools or gauges. During the processing, it is automatically selected and replaced by the program. This is the main difference between it and CNC milling machines and CNC boring machines. Especially for workpieces that must use tooling and special equipment to ensure product quality and efficiency. This will save a lot of time and cost for the development and modification of new products, so that enterprises have strong competitiveness.

Machining centers are often divided into vertical machining centers and horizontal machining centers according to the state of the spindle in space.

A machining center whose spindle is in a vertical state in space is called a vertical machining center. A machining center whose spindle is in a horizontal state in space is called a horizontal machining center. A machining center whose spindle can be converted vertically and horizontally is called a vertical-horizontal machining center or a five-sided machining center, also known as a compound machining center.

According to the number of columns in the machining center, it is divided into single-column type and double-column type (gantry type).

According to the number of motion coordinates and the number of coordinates controlled simultaneously, the machining center is divided into three-axis two-linkage, three-axis three-linkage, four-axis three-linkage, five-axis four-linkage, six-axis five-linkage, etc.

Three-axis and four-axis refer to the number of motion coordinates of the machining center. Linkage refers to the number of motion coordinates that the control system can control simultaneously, thereby realizing the position and speed control of the tool relative to the workpiece.

According to the number and function of worktables, it can be divided into single-table machining center, double-table machining center, and multi-table machining center.

According to machining accuracy, it can be divided into ordinary machining center and high-precision machining center.

Ordinary machining center: resolution is 1μm, maximum feed speed is 15-25m/min, and positioning accuracy is about 10μm.

High-precision machining center: resolution is 0.1μm, maximum feed speed is 15-100m/min, and positioning accuracy is about 2μm. Between 2 and 10μm, ±5μm is more common, which can be called precision grade.

The configuration of the CNC machining center is very important. A good CNC machining center must have a good configuration. What determines the quality of the CNC machining center is not only excellent components, but also rigorous assembly and reasonable matching.

The market share of the CNC system of the machining center is basically controlled by European, American and Japanese brands.

The high-end is Japan's FANUC and Mitsubishi, and Germany's Siemens. The mid-range is divided by systems such as Taiwan Baoyuan, Taiwan Xindai and some Chinese brands.

The system of the five-axis stereo machining center is recommended to use Siemens 840D or Fanuc3l. It is not that high-end CNC machining centers are demanding, but in the world of five-axis machining centers, the gap between domestic and world advanced levels is very large. In the three-axis and four-axis stereo machining centers for high-speed and high-precision machining, Fanucl8i and Mitsubishi M70 are indistinguishable.

In general three-axis stereo machining centers, FanucOi and Mitsubishi M70 are a pair of happy enemies. FanucOi MD-A is suitable for mold processing. FanucOi MD-B is suitable for product processing. FanucOi Mate-MD is an economical system. Mitsubishi M70 is suitable for mold machines. Mitsubishi M70-B is suitable for product machines. It is generally believed that Fanuc is easier to operate and more stable, while Mitsubishi of the same grade is more powerful.

In situations where the requirements are not high and the budget is limited, domestic CNC systems can also show their talents. To be fair, in recent years, domestic machining center systems have developed rapidly, and it is their progress that has forced the prices of foreign CNC system brands to drop sharply. Taiwan's Baoyuan and Xindai are mainly used in the engraving and milling machine industry.

In the electrical system of the three-dimensional machining center, GE of the United States, Schneider of France, and Omron of Japan occupy the mainstream position. Among the low-end models, there are also shadows of domestic Chint and domestic Delixi.

With the maturity of spindle servo technology and the reduction of prices, frequency converters have gradually withdrawn from the field of three-dimensional machining centers because they cannot solve the problem of rigid tapping.

The matching between electrical components is critical. The coordination and adaptability of electrical performance determine the stability of the electrical system. Not all components using the same brand can solve the compatibility problem. The quality of compatibility requires precise calculation, experience and technical accumulation.

Good lubrication is a necessary condition to ensure the smooth mechanical movement of the three-dimensional machining center. All parts that have contact movement need to be lubricated. Without a lubrication system, the life and accuracy of the CNC machining center will be greatly affected. Carefully observing the oil lubrication system of the CNC machining center is a compulsory course before purchasing a three-dimensional machining center.

The bearing seat, nut seat, guide rail, and ball screw of the screw must be accessible by oil. At the same time, it is necessary to consider whether the oil circuit layout is reasonable and whether maintenance and replacement are convenient.

CNC machining centers with chaotic oil circuit wiring, mixed and interfered oil pipes and other pipelines, and lack of lubrication of the main moving parts cannot be purchased.

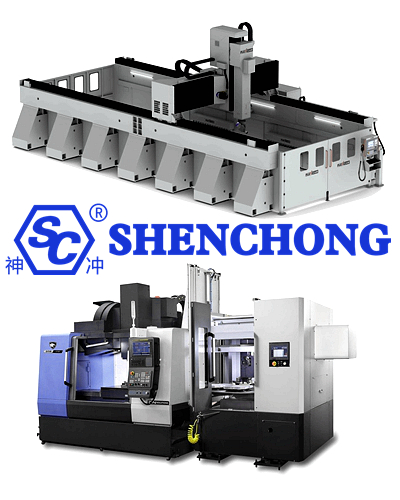

There are many types of machining centers. Such as drilling and tapping centers, vertical machining centers, horizontal machining centers, gantry machining centers, milling and boring machines, etc.

Different machining centers specialize in different types of products. It is very important to choose a manufacturer that can meet your specific processing needs.

Price is mainly affected by factors such as material cost, labor, and equipment. When choosing, mainly consider your budget range and price factors.

Quality is one of the key factors in choosing a CNC machining center. Quality may affect production efficiency, machining accuracy, durability, etc. Therefore, it is very important to choose a reputable manufacturer with guaranteed quality and quality control.

- Three axis machining center: suitable for flat machining, fine carving and other needs. The price is relatively affordable.

- Four axis machining center: capable of processing additional rotation axes, suitable for multi angle and curved surface machining. The price will be higher compared to the three axis.

- Five axis machining center: wider machining angle. For example, the mechanical processing of complex parts such as aerospace and automobiles requires the use of five axis machine tools. The performance and price are relatively high.

- Electric spindle power: The larger the power, the more suitable it is for heavy cutting. But the disadvantage is that it consumes a lot of electricity.

- Motor power: The maximum power of a machining center determines the material to be machined, cutting depth, cutting speed, etc. But excessive power can cause energy waste.

When selecting a machining center, it is necessary to consider the accuracy requirements of the processed parts. Generally speaking, the higher the precision of the machine tool, the more precise the process equipment required, and the corresponding price will also increase.

First, you need to clarify the size of the object you need to process, in order to choose a suitable machining center. Of course, if you buy large, you can also process small parts, while if you buy small, you can only process small parts. Therefore, it is recommended to choose a slightly larger processing range.

Although the five axis machine tool has strong processing capabilities, it is also more complex. More manpower and resources are needed for maintenance. Therefore, when selecting machine tools, it is necessary to fully consider their after-sales maintenance services and provide training for the personnel and equipment of one's own enterprise.

Choosing an appropriate CNC machining center can improve the production efficiency of enterprises and better showcase the technological content of the manufacturing industry. Finally, it is emphasized again that attention should be paid to multiple aspects such as model, power, accuracy, processing volume, and after-sales maintenance when selecting.

In today's competitive market, choosing a suitable CNC machining manufacturer is crucial for enterprises. The application of CNC machining technology has penetrated into various industries. From automobile manufacturing to aerospace, from medical devices to electronic products, high-quality and high-precision CNC machining parts are required.

Therefore, choosing an excellent CNC machining manufacturer has become a key decision in the development of enterprises.

First, choose a CNC machining manufacturer with rich experience. Experienced manufacturers usually understand customer needs better and can provide more professional technical support and solutions. They have a deep understanding of material properties, processing technology and quality control, and can ensure product quality and delivery cycle.

Second, the equipment and technical level of the CNC machining manufacturer should be examined. An advanced CNC machining manufacturer usually has the latest machining equipment and technology to meet the needs of different customers. For example, five-axis CNC machining, turning machining, milling machining, etc. are all important indicators to measure the technical level of a manufacturer. In addition, whether the manufacturer has relevant certifications such as ISO9001 is also an important basis for evaluating its quality management system.

Third, the production capacity and delivery capacity of the CNC machining manufacturer should be considered. With the continuous growth of market demand, customers often need to obtain large quantities of parts in a short period of time. Therefore, it is very important to choose a CNC processing manufacturer that can guarantee timely delivery. The manufacturer's production capacity, the utilization rate of production equipment, and the supply chain management capabilities are all important factors affecting delivery capabilities.

Finally, it is necessary to examine the service level and after-sales support of the CNC processing manufacturer. Good pre-sales consulting services, production progress tracking, and timely after-sales technical support can help customers solve various problems in the production process and ensure the smooth completion of orders. Therefore, when choosing a CNC processing manufacturer, its service level and after-sales support capabilities should be comprehensively considered.

In summary, choosing an excellent CNC processing manufacturer is an important task in the development of an enterprise. Experienced, advanced technology, strong production capacity, and thoughtful service CNC processing manufacturers will provide customers with the best processing services and help enterprises achieve a higher level of development. I hope that the above suggestions can help you choose the most suitable CNC processing manufacturer to escort the development of the enterprise.

Click here to know:

Top 10 Best Brands Of CNC Machine Manufacturers 2024