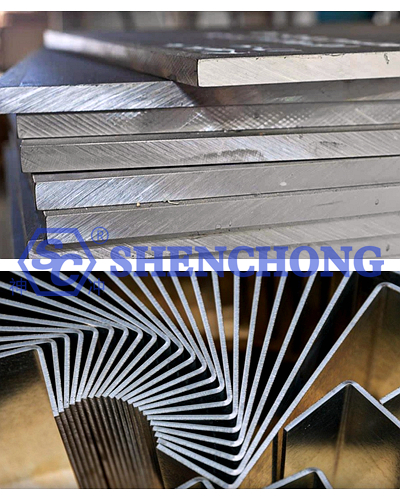

High-strength steel is a type of steel with extremely high tensile strength, mainly used in various large-scale projects, construction, and automobile bodies. Compared with ordinary steel, high-strength steel has higher strength and hardness, and better wear resistance.

High-strength steel is widely used in engineering, construction and automobile fields, such as bridges, high-rise buildings, large machinery and automobile bodies. In these fields, the tensile strength and hardness of high-strength steel enable it to withstand greater loads and pressures, ensuring the safety of engineering and vehicles. At present, high-strength plate bending parts are mainly used for structural parts in automobile chassis.

There are two methods of high-strength steel bending: one is stamping bending, which requires the bending mold to fit the sheet metal perfectly and correspond to the sheet metal part one by one. The mold development cost is high and it is suitable for sheet metal parts with complex structures; the other is bending by a bending machine.

The bending mold does not need to correspond to the sheet metal part one by one. By adjusting the bending process and the bending machine stroke, the bending mold can be produced flexibly to meet the needs of different bending parts. The mold development cost is low and it is suitable for sheet metal parts with simple structures.

In order to ensure the bending quality of high-strength steel, certain processing technologies need to be adopted. Common processing technologies include pre-bending method, multiple bending method, side support method, etc. Among them, the side support method can make the bending process more stable and avoid the destruction of the ultimate strength.

The strength of high-strength steel plates is higher than that of ordinary steel plates, and their bending strength is also higher. Therefore, the bending direction must be consistent with its strength direction to obtain the best bending quality.

High-strength steel plates are prone to breakage or produce a large rebound angle when bending. Therefore, the bending angle needs to be controlled during the bending process to avoid exceeding the bending limit of the high-strength steel plate.

In the bending process of high-strength steel plates, it is necessary to control the position and number of pressure and support points to ensure smooth bending and avoid deformation or cracking.

The processing technology of high-strength steel plates requires special attention, such as the tool angle and cutting speed of the processing tool, which will affect the bending quality of high-strength steel plates.

When the inner R angle of the bend is small to a certain value, the outer longitudinal material of the sheet may be deformed too much, causing cracks or microcracks at the R angle of the bent part. In the early stage of trial production of high-strength steel bent parts, bending cracking defects frequently occurred, which not only caused waste of sheet materials, but also affected the normal progress of the project. The main factors causing cracking of high-strength steel bent parts are as follows.

The limit bending radius to prevent the outer fiber from cracking is called the minimum bending radius. The minimum bending radius is related to the mechanical properties of the material, the fiber direction of the sheet, the surface quality and side quality of the sheet, and the thickness of the sheet. Generally speaking, as the strength of the material increases, the plasticity will decrease, and the minimum bending radius that the material can adopt will be larger.

In addition, cold-rolled sheets are generally anisotropic, and the plasticity index along the fiber direction is greater than the index perpendicular to the fiber direction. Therefore, when the bending line is perpendicular to the fiber direction of the sheet, the minimum bending radius is small.

In order to avoid bending cracking or microcracks, it is necessary to predict the minimum bending radius of the sheet in advance. For example, the bending radius of protective steel BP500 (yield strength not less than 1250MPa) is not less than 4 times the material thickness, and the bending line must be perpendicular to the fiber direction of the sheet.

In order to avoid cracking of the bent parts due to too small bending radius, it is necessary to focus on the relationship between the bending radius and the minimum bending radius of the material and the relationship between the bending line and the fiber direction of the sheet during the digital model review stage.

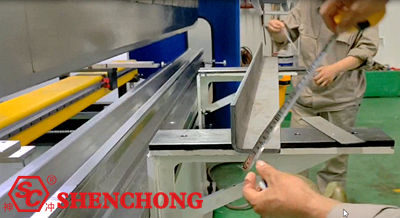

During the bending process, the bending line needs to be positioned to ensure the accuracy of the bent parts. The traditional manual line positioning methods mainly include manual or laser marking positioning method, process notch positioning method and machine tool block positioning method.

When the plate adopts the bending process, there are high requirements for the surface quality and side quality of the material. There must be no cracks, scratches on the surface or burrs, notches and other defects on the side. Therefore, the process notch positioning method cannot be used for bending positioning of such plates, and the machine tool block positioning method with no damage to the plate should be used for bending.

When the bent part is taken out of the mold, the bending angle and bending radius are inconsistent with the mold, which is called bending springback. The main factors affecting the springback of the bent part are: mechanical properties of the material, relative bending radius r/t, bending method, bending center angle and shape of the bent part.

The size of the springback angle is proportional to the yield strength and hardening index of the material, and inversely proportional to the elastic modulus. The yield strength of protective steel BP500 is not less than 1250MPa, so its springback trend is much greater than that of ordinary plates.

The main methods to improve the accuracy of bent parts include changing the local structure of the bent parts, selecting materials with low yield strength and large elastic modulus, replacing free bending with corrective bending and die compensation methods. Due to the shape restrictions of the bent parts, it is not possible to add reinforcing ribs at the bend. The bending springback of BP500 plates is mainly improved by die compensation method.

Due to modeling requirements, some bending parts have large holes near the bending line. Bending is performed after the hole blanking is completed, and the profile of the bent part near the hole position is warped, affecting the installation of other parts. The hole blanking method is adjusted, the large hole is partially punched out, and part of the connecting strip is retained. After the bending is completed, the remaining part of the hole is processed out. This method can significantly improve the profile warping problem, improve the profile flatness of the bent part, and ensure the installation of parts.

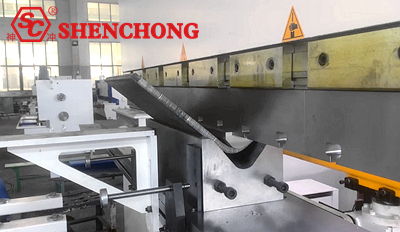

During the bending process of BP500 material bending parts, it was found that some bending parts with longer bending lines had inconsistent bending angles at the left and right ends.

The reasons for the inconsistent bending angles of the left and right ends of the bending parts are:

- The parallelism of the slider of the bending machine with the worktable plane exceeds the tolerance when it reaches the bending end position.

- The parallelism of the mounting surface of the upper die and the working bottom surface exceeds the tolerance.

- The parallelism of the V-groove of the bending lower die and the mounting bottom surface exceeds the tolerance.

- The thickness of the folded sheet is inconsistent on the left and right ends, etc.

When the bending lower die is rotated 180°, that is, the left and right ends are turned around and bent, the angle difference between the left and right ends of the bending part still exists, and the size value is swapped left and right.

It is speculated that the left and right ends contact position is different when the bending upper die and the bending lower die are closed. After further investigation, it was found that the arc size of the working bottom surface of the bending upper die was inconsistent, resulting in the parallelism of the mounting bottom surface of the bending upper die and the working bottom surface exceeding the tolerance, which led to the inconsistent bending angles on the left and right. By reprocessing the arc of the working bottom surface of the bending upper die, the flatness reaches 0.05mm/m, and the problem of inconsistent bending angles at the left and right ends of the bent part is solved.

In summary, when free bending high-strength steel plates, it is necessary to first test and obtain its minimum bending radius and springback trend, and on this basis ensure the consistency of CNC press brake machine accuracy, mold accuracy and sheet thickness, and then optimize and adjust the free bending process of the press brake bending machine, such as optimizing the positioning method, etc., which can effectively reduce the defects of high-strength steel bending parts and improve the product qualification rate.