The fiber laser beam quality refers to the diameter, divergence angle, wavefront distortion and other parameters of the beam, which directly affects the application range and accuracy of the laser.

Good beam quality is characterized by small beam focal spot, small beam divergence, uniform spot, and high phase sinusoidal degree. By optimizing the design and adjusting parameters, the beam quality can be improved to meet different application needs.

The beam quality of a laser refers to the optical quality of the laser output beam when it propagates freely. Beam quality is one of the key technical parameters in lasers and laser processing.

- Beam parameter product (BPP) is the product of the beam radius at the beam waist and the far-field beam divergence angle

- The M2 factor is defined as the product of beam parameters divided by the corresponding product of diffraction-limited Gaussian beams with the same wavelength

A low value of BPP or M2 factor means high beam quality.

High beam quality means a smooth wavefront (i.e. strong phase correlation across the beam profile). Focusing a beam with a lens therefore allows one to obtain a focal point where the wavefront is planar. Scrambling the wavefront makes focusing the beam more difficult, i.e. the beam divergence for a given spot size increases.

Beam quality is one of the important indicators to measure the performance of fiber lasers. It is usually described by parameters such as beam radius, divergence angle, and wavefront distortion. Among them, the smaller the beam radius and the smaller the divergence angle, the stronger the focusing and transmission capabilities of the beam. The smaller the wavefront distortion, the higher the accuracy and stability of the laser.

The quality of the internal structure of the laser determines the beam characteristics of the laser output.

For example, gas lasers and solid-state lasers output different beam qualities. The same type of laser produces different beam qualities due to different output powers.

The optical components within the laser have an important impact on the beam quality.

For example, whether the surface of the optical element through which the laser beam passes has optical reflection capabilities, optical transmittance, surface flatness and other characteristics will affect the beam quality.

Factors such as the monochromaticity of the light source, the geometry of the beam, the lateral and longitudinal coupling of the beam, and the wavelength of the beam also affect the beam quality.

The beam quality of fiber lasers is affected by many factors, such as fiber quality, laser design and manufacturing process, etc. Among them, fiber quality is one of the important factors affecting beam quality. The quality of optical fiber determines the loss and distortion of light transmission, which directly affects the quality of the light beam. In addition, the design and manufacturing process of the laser will also have an impact on the beam quality.

Beam quality is usually described using the M2 value. The M2 value is a comprehensive parameter that reflects the beam focusing ability and transmission ability.

The smaller the M2 value, the better the quality of the beam, and the stronger the focusing and transmission capabilities. In actual applications, it is necessary to select the appropriate M2 value according to specific needs to obtain the best application effect.

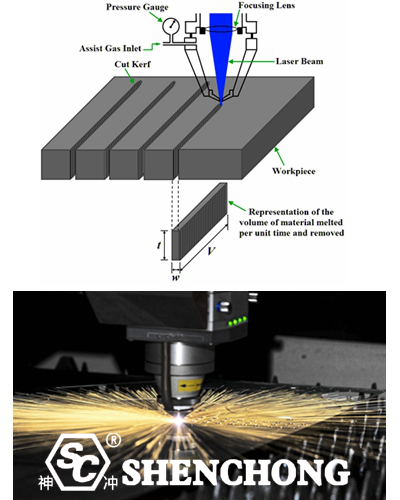

The beam quality of the laser has a great influence on the laser processing process in practical applications.

For example, lasers with good beam quality can better realize small-size engraving, fine processing, high-speed cutting and other scenarios, and are also widely used in welding, marking, anti-counterfeiting and other fields.

High beam quality may be important when a strongly focused beam is required. In the field of laser material processing, printing, marking, cutting and drilling often require high beam quality. Welding, brazing, hardening and various other types of surface treatments are less important in this regard. Because they process larger spots, high-power laser diodes with relatively poor beam quality can be directly applied (direct diode lasers).

For cnc fiber laser cutting machine and remote welding, relatively high beam quality (M2≤10) allows the use of large working distances (i.e. the distance between the workpiece and the focusing objective). This is much needed. For example, to protect optics from debris and smoke.

Additionally, high fiber laser beam quality reduces the beam diameter in the beam delivery system. This allows the use of smaller, cheaper optical components such as mirrors and lenses. Also increasing the effective Rayleigh length (for a given spot size) increases the tolerance for longitudinal alignment.

In summary, the beam quality of lasers has an important impact on laser application fields. In the actual application process, factors such as the internal structure of the laser, optical components, and light source characteristics need to be comprehensively considered to continuously optimize the beam quality to meet the needs of practical applications.

The reason why fiber laser beam quality is important is that it is a key physical quantity that determines the quality of the laser and whether it can perform laser precision processing.

For many types of single-mode output lasers, high-quality lasers usually have high beam quality, corresponding to a small M2. Improving beam quality is one of the important means to improve the performance of fiber lasers.

Commonly used methods include:

Choose high-quality, low-loss fiber. Reduce the nonlinear effects and diffraction losses of optical fibers.

Select appropriate laser structures and materials, and control parameters such as temperature and pressure during the manufacturing process.

Shape and correct the distortion of the beam to improve the quality and stability of the beam.

The beam quality of fiber laser is one of the important indicators that affects the performance and application of the laser. Through reasonable design and adjustment, the beam quality can be improved to meet different application requirements. In practical applications, it is necessary to select the appropriate fiber laser beam quality and M2 value according to specific needs to obtain the best application results.