CNC Tube Laser Cutting machine is a kind of equipment that uses laser technology to cut and process tubes. It uses a high-energy density laser beam to irradiate the surface of the tube, causing it to heat up rapidly and melt, and vaporize, thereby achieving precise cutting of the tube. CNC Tube Laser Cutting machine can process tubes of various shapes and sizes, including circular, square, rectangular, and various special shaped tubes.

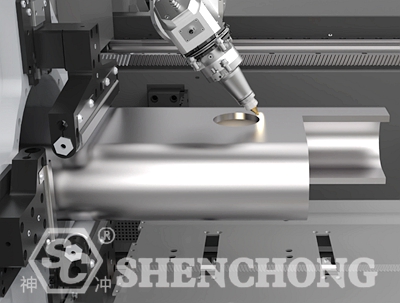

CNC Tube Laser cutting machine is a metal processing equipment used to process metal tubes into various shapes, such as circles, squares, triangles, etc. It usually consists of laser generator, control system, manipulator, cutting head, operating table, and other parts.

The laser generator generates high-energy laser, and the control system controls the manipulator movement and the laser scanning path as needed. The manipulator can grab the tube through the fixture and move it under the cutting head, which will cut the tube along the preset path.

Compared with traditional processing methods, laser tube cutting machines have many advantages, such as high processing accuracy, fast cutting speed, smooth cutting, and small heat affected zone. Tube Laser cutting machine is suitable for processing various metal pipe fittings, especially for large-sized and complex shaped pipe fittings, with better results. Meanwhile, since laser achieves processing goals by directly changing the energy of light, there will be no mechanical noise or pollution issues during the processing.

In industrial production, laser tube cutting machines are widely used in the field of metal pipe processing, such as construction, machinery manufacturing, automobile manufacturing, aerospace and other industries, for manufacturing various structural components and parts.

The construction industry is one of the main application scenarios for laser tube cutting machines. Modern architecture requires the large use of various metal pipes, such as steel pipes, stainless steel pipes, aluminum alloy pipes, etc. The laser tube cutting machine can perform high-precision cutting on these pipes, thereby realizing the production of building products such as doors, windows, stair handrails, and railings.

Laser tube cutting machines are also widely used in the automobile manufacturing industry. The automobile production line requires a large amount of various pipes, such as water pipes, oil pipes, gas pipes, etc. Laser cutting technology can cut pipes that meet the requirements at high speed, high efficiency and precision, greatly improving the production efficiency of automobile production lines.

Tube laser cutting machines have also been widely used in the furniture manufacturing industry. For example, the traditional processing method for tubes used to make furniture such as chairs and tables requires the use of various tools for cutting, punching, and other operations, which is time-consuming, labor-intensive, and difficult to ensure quality. Laser cutting technology can achieve one-time precise cutting, improving production efficiency and product quality.

Due to its high speed, efficiency, and precision, laser cutting technology has also been widely used in the manufacturing of pressure vessels. In the manufacturing process of pressure vessels, some metal plates need to be cut, spliced, and welded, the laser tube cutting machines can complete these operations at high speed and high precision.

Tube laser cutting machines are often used for pipeline processing. For pipeline processing, it is not only necessary to cut accurately and efficiently, but also to ensure the roundness and straightness of the pipeline, as well as to avoid quality problems such as cracks. Laser tube cutting machine has high stability and precision, which can meet the needs of pipeline processing.

There are many laser cutting machine manufacturers on the market now, with a wide variety of types and qualities. How to choose suitable equipment that meets our own needs has become a challenge. We believe that the following 10 factors are something you need to pay special attention to when purchasing a tube laser cutting machine.

For laser tube cutting machines, the tube material and size directly affect the cutting ability. Before making a purchase, you need to first clarify your cutting requirements:

What is the material of the tube you need to cut? Carbon steel, stainless steel, aluminum alloy, or other metals? What are the dimensions of the tube, including diameter, side length, length, wall thickness, and weight?

These factors will directly determine which model laser cutting machine we need to choose. Generally speaking, the higher the power, the larger the size of the tube that can be cut and the wider the variety.

Cutting accuracy and cutting speed are the most important indicators to determine the performance of tube laser cutting machines. High precision and high speed mean higher production efficiency and lower production costs.

When choosing equipment, we need to pay attention to whether the cutting accuracy of the equipment can meet our processing requirements, whether the cutting speed can adapt to your production rhythm. We suggest that you focus on indicators such as machine positioning accuracy, repeated positioning accuracy, maximum idle speed, maximum acceleration, chuck speed, etc.

When purchasing, the length of the pipe tail after cutting, and whether the laser machine can cut the groove. Among them, the length of the pipe tail is related to the material utilization rate, which in turn determines the user's raw material procurement cost.

And bevel cutting can provide convenience for subsequent welding and other processes, greatly reducing the workflow and improving work efficiency.

Laser is the core component of laser tube cutting machine, and its brand and power directly affect the performance and service life of the equipment.

At present, the well-known laser brands on the market include IPG, Raycus, Trumpf, Max, etc. When choosing, it is recommended to prioritize famous brand laser, and select the appropriate power according to your processing needs.

With the development of industrial automation, more and more enterprises hope to reduce labor costs and improve production efficiency by increasing the automation level.

The automation level of laser tube cutting machine is mainly reflected in functions such as automatic loading and unloading device, automatic focusing, and automatic following. Choosing equipment with a high automation level can reduce manual operations and improve production efficiency.

The operating system and software functions of the laser cutting machine are crucial for the ease of use and functional expandability of the equipment.

Modern laser tube cutting machines are usually equipped with easy to operate user interfaces and powerful software functions, such as automatic typesetting, automatic nesting, cutting path optimization, fault diagnosis, and other more function.

When making a purchase, it is necessary to ensure that the operating system and software of the equipment can meet our operating habits and production needs.

In order to make sure stable long-term use, you also need to pay attention to the brand of the core components equipped with the laser cutting machine, including the laser, cutting head, control system, machine body and accessories, electrical and pneumatic systems, servo motors and drivers, water cooler, transmission system, etc.

In general, the quality of components produced by brands with advanced technology and a long history is more guaranteed, so we recommend choosing tube laser cutting machines that use components from international brands.

When choosing a tube laser cutting machine, it is also necessary to consider the floor space of the equipment and factory layout.

Different machine models have different floor spaces, and you need to choose the appropriate equipment based on the actual situation of the factory.

In addition, the layout of the equipment also needs to consider the convenience of material flow and the coordination of the production line.

As is well known, the power supply and voltage used for industrial electricity in different countries are not the same. According to the number of phases, it is divided into single-phase, two-phase, and three-phase electricity, with a voltage range of 110-380V.

Therefore, if the power supply and voltage provided by the manufacturer for the machine are different from those in your region, please contact the manufacturer to confirm the wiring method and perform professional electrician operation.

The energy consumption and maintenance costs of laser cutting machines cannot be ignored during long-term use. Efficient lasers and reasonable equipment design can effectively reduce energy consumption and operational costs.

In addition, the cost of machine maintenance also needs to be taken into consideration. Choosing equipment that is easy to maintain and has easily replaceable spare parts can reduce the difficulty and cost of daily maintenance.

Choosing a laser tube cutting machine is a complex project that requires comprehensive consideration of multiple factors. From the cutting material type and the cutting thickness, to the equipment automation, energy consumption and maintenance costs,. All of these will directly affect your production efficiency and product quality. Hope that through these key points, you can better understand and purchase the suitable cnc tube laser cutting machine.