The three-roller plate bending machine is a widely used equipment in the metal processing industry, mainly used to roll metal sheets into cylindrical, curved, or conical shapes. Its working principle is complex and precise, involving the collaborative work of multiple components.

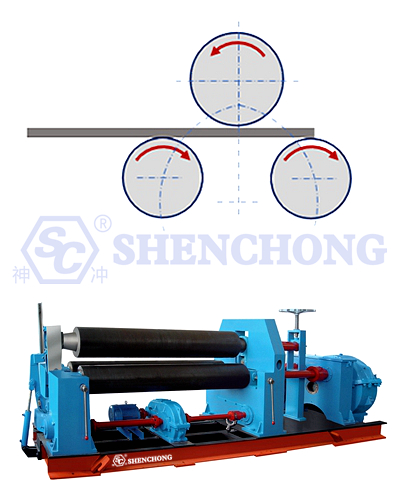

The three-roller plate bending machine is mainly composed of three key components: upper roll, lower roll, and side roll. During work, the upper roller and lower spoke cooperate with each other through a transmission device to produce undulating motion, sandwiching the sheet metal between them for processing.

Specifically, the upper roller is usually located in the center, while the lower roller is symmetrically arranged on both sides. The side rollers are located between the upper and lower rollers, and are in contact with the side surface of the sheet metal through a clamping mechanism to prevent the sheet metal from sliding during the processing.

During the processing, the rotation directions of the upper and lower rollers are opposite, and the rollers generate rotational motion through the power provided by the hydraulic system or mechanical transmission device. This rotational motion causes the metal sheet to bend and gradually curl into the desired shape. At the same time, the side rollers will adjust their position and pressure as needed to control the bending angle and the diameter of the coil, ensuring that the processed products meet the accuracy requirements.

The working principle of the three roll plate rolling machine is based on the gradual bending of metal sheets into cylindrical or conical work pieces under pressure and compression caused by the interaction of three rollers. It gradually shapes the flat plate through the combination of upper and lower rollers and the movement of the sheet.

The following is a detailed explanation of the working principle of the three roll plate rolling machine:

The upper roller is the main roller, which applies downward pressure to the sheet and bends it. The upper roller is usually movable up and down, used to adjust the bending radius of the sheet metal.

Two lower rollers are used to support the sheet and drive the sheet to move forward and backward through rotation. The lower roller is responsible for providing friction to propel the sheet forward, ensuring smooth movement of the sheet during the bending process.

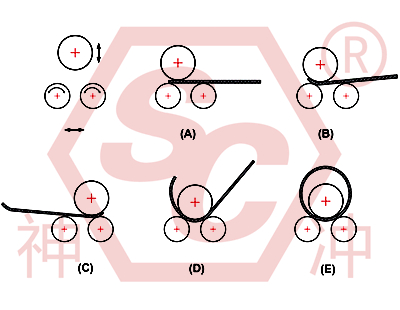

There are multiple methods for rolling process, and users can decide according to their own process. The following is provided for reference.

Operate the upper roller to rise so that the distance between the plane formed by the lower busbar of the upper roller and the upper busbar of the lower roller is slightly greater than the thickness of the working plate.

Then, horizontally feed the steel plate into it, aligning the end of the steel plate with the entire line of the upper roller, and then lower the upper roller to press and contact the steel plate.

Operate the upper roller to descend, repeat the operation to rotate the lower roller, lower the upper roller, and roll it into the desired arc or cylinder shape.

When bending a small diameter cylindrical shape, the minimum bending diameter can be calculated as 1.25R, which is the upper roller diameter multiplied by a coefficient of 1.25.

When preparing to unload, first remove the inverted head pin (note), raise the upper roller to the position where the crossbeam presses the upper roller head, and slightly lift the tail of the upper roller to tilt the inverted head and unload the work piece;

Before rolling, some three roll bending machines (especially asymmetric three roll bending machines) can pre bend both ends of the sheet to avoid the problem of incomplete forming at the end of the sheet.

The pre bending function adjusts the position of the rollers and applies additional pressure to pre bend the end of the sheet before formal rolling, ensuring that the curvature of the entire sheet is consistent.

Due to the fact that the initial rolling may only partially bend the sheet, in the actual production process, it is usually necessary to roll the sheet multiple times between rollers to gradually achieve the desired curvature and roundness.

For a symmetrical three roll plate rolling machine, the sheet may need to be fed in reverse to ensure that the other end of the work piece can also be rolled to the same curvature. By repeatedly reversing the feeding direction, gradually complete the rolling of the entire board.

After the board has been pressed multiple times to achieve the desired circular or conical work piece, the position of the upper roller can be adjusted to remove the formed work piece from the machine. The bending radius and shape of the work piece depend entirely on the pressure applied by the upper roller, as well as the number and path of plate movement.

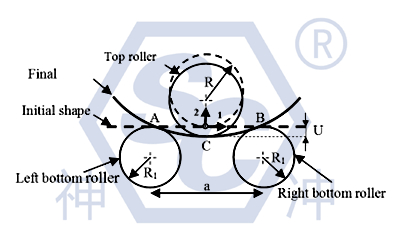

The rounding principle of a three roll plate rolling machine can be summarized as follows:

By adjusting the up and down movement of the upper roll, a bending force is applied to the plate, and the rotation of the lower roll causes the plate to move back and forth between the upper and lower rolls, gradually forming the desired cylindrical or conical work piece.

In the rolling process, the force on the sheet is mainly achieved through the pressure of the upper roller and the support and pushing effect of the lower roller. The pre bending function and repeated rolling ensure the complete bending of the work piece and the accuracy of the final shape.

The three roll plate rolling machine has mechanical and hydraulic types. Mechanical three roll plate rolling machines are divided into symmetrical and asymmetrical types.

The performance characteristics of the mechanical three-roller symmetrical plate bending machine are as follows:

The structural type of the machine is a three roll symmetrical type. The upper roller moves vertically up and down at the symmetrical position of the center of the two lower rollers, which is obtained through the transmission of a screw and a worm.

The two lower rollers move in rotation, and the output gear of the reducer meshes with the gear of the lower roller to provide torque for rolling the plate. The disadvantage of this machine is that the end of the board needs to be pre bent with the help of other equipment.

The main features of the mechanical three roll asymmetric plate rolling machine are as follows:

The structure of the machine is a three roll asymmetric type, with the upper roll as the main transmission and the lower roll moving vertically to clamp the plate. The lower roll gear meshes with the upper roll gear and serves as the main transmission.

The edge roller performs tilting and lifting motion, with dual functions of pre bending and curling. Compact structure, easy to operate and maintain. Technical parameters: Specification, model, maximum thickness of the rolled plate.

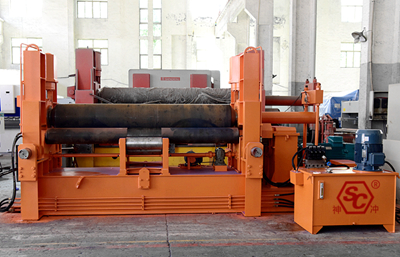

The main features of the hydraulic three roll symmetrical plate rolling machine are:

The upper roll of the machine can be vertically raised and lowered, and the vertical lifting hydraulic transmission is obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod. The lower roller is driven to rotate, and there is a support roller at the lower part of the lower roller that can be adjusted.

The three roll plate rolling machine can effectively control the bending radius when rolling cylindrical and conical work pieces, making it suitable for medium precision rolling work.

The three roll plate rolling machine is suitable for rolling various metal materials, such as carbon steel, stainless steel, aluminum alloy, etc. Different thicknesses of plates can be processed by adjusting the distance between the upper and lower rollers.

Some asymmetric three roll plate rolling machines have pre bending function, which can pre bend both ends of the plate before rolling, reduce material waste, and improve the accuracy of the workpiece.

The three roll plate rolling machine has a simple structure and easy operation, and is usually suitable for small and medium-sized enterprises or occasions that require medium roll workpieces.

Due to the continuous rotation of the rollers, the three roll plate rolling machine is suitable for medium batch production tasks.

During the pre bending process of a symmetrical three roll bending machine, there may be material ends that cannot be fully bent into place and require subsequent trimming work.

The three roll plate rolling machine is suitable for rolling medium thickness plates. For extremely thin or thick plates, other types of plate rolling machines may be required for processing.

In general, the working principle of a three roll plate rolling machine is to bend the metal sheet into the desired cylindrical, curved, or conical shape through the coordinated motion of the upper roll, lower roll, and side roll.

By adjusting parameters such as the position, angle, speed, and pressure of the rollers, rolling work with different accuracies and requirements can be achieved. Meanwhile, the application of auxiliary devices has further improved the efficiency and stability of the equipment.

In practical applications, the three roll plate rolling machine is widely used in industries such as shipbuilding, boilers, aviation, hydropower, chemical engineering, metal structures, and machinery manufacturing, making important contributions to the development of the metal processing industry.