What is a numerical control system? Simply put, it is a digital control system, which is to control one or more machines and equipment through digital instructions to achieve the desired control purpose.

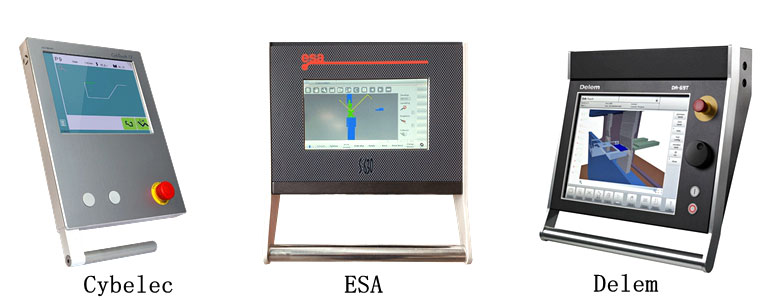

For the CNC controller for press brake, with the development of the bending machine in recent years, various systems have appeared on the market, such as the Cybelec series in Switzerland, the DELEM series in the Netherlands, the ESA series in Italy, the MD series in Hong Kong, the Nanjing SNC series, etc.

So how to choose a dazzling array of systems? It is estimated that this has made many customers difficult.

In fact, it is much simpler as long as you follow the following estimates.

The system must be simple and convenient to operate.

The purpose of our use of CNC press brake is to bring us convenience and create more value for us. If the controller design is complicated and the operation is cumbersome, then this system may not be suitable for us no matter how good it is.

Imagine that the system operation of our employees is a problem, can it still give full play to the efficiency and accuracy of the system? So an excellent CNC controller must be simple to operate, easy to learn and easy to use.

The system must be stable. Everyone knows that we don’t want the machine to go wrong after just a few days of purchase, which affects our mood and delays production.

So how do we know that the system is stable?

- We need to look at the number of years it has existed in the market and its reputation and holdings, and whether the product is mature or not.

If a product has not been tested and affirmed by the market, then the system is not mature, and there will inevitably be such small problems.

This phenomenon is like a copycat mobile phone and an Apple mobile phone, the appearance is the same, but the difference is far.

- We depend on the system manufacturer, the system produced by the senior automation manufacturer will be more stable.In fact, the essence of CNC machine tools is mechanical automation.

Generally, college students can develop them but few can be successfully applied. What is the reason? In fact, the ideal environment is far from the actual environment. Without a core technical team, it is impossible to develop a satisfactory system.

- See whether the manufacturer’s after-sales service is timely. After-sales service is an important condition for the quality of a beam manufacturer.

For the machine, it is inevitable that there will be problems, but as long as the after-sales service can be provided and handled in time, it is understandable and acceptable.

Know more about CNC Press Brake Machine For Sale

Based on the above conditions, we recommend the following 3 brands of CNC Controller for press brake:

The series of CNC controller for press brakes produced by Delem in the Netherlands, among which the more common models are DA52 (discontinued), DA53T, DA56, DA58T, DA66T, DA69T.

The difference between 56 and 58T is whether it is a touch screen or not, and the other configurations are the same.

DA56 is the button. Some customers do not want to use the touch screen, thinking that the button can be used longer.

Therefore, in addition to the different functions of each model, the final choice must also consider the customer’s own preferences.

The CNC system produced by Cybelec of Switzerland, including models of DNC60, 600s, 880s, and touch screen series CT8/CT8 PS/CT12 PS/CT15.

All CybTouch are equipped with CybTouch Tools, which can transmit wirelessly between PC and CybTouch (requires optional RFLink USB tool).

It can be used to store/restore machine parameters, molds and products, and can be used to upgrade products.

The model series produced by Italian ESA CNC control system are 500 series and 600 series, among which the common ones are S530, S540, S630, S640, S650, S650W, S660W.

In comparison, the S630 model is the most economic. It can simulate bending, perform data programming and 2D graphics programming, and can meet most of the bending needs.

Except for 650W and 660W, which are touch screens, the difference between other models lies in the screen size, such as S530 screens with 7 inches and S630 screens with 10 inches, and S660w screens with 19 inches.

The above three brands are all professional CNC controller manufacturers, and in order to facilitate users to make more targeted choices.

The following briefly introduces their respective advantages and disadvantages:

– CYBELEC, as the first company in the world to develop a special CNC controller for press brakes, is undoubtedly professional. But at the same time it’s very test the customer’s operational level and requires professional workers to operate.

– On the contrary, the advantage of DELEM is that it’s simple to operate, but its cost is high. Under the same function, its price is the highest of the three.

– In contrast, ESA combines the advantages of the first two in one: the most cost-effective, and the operation is relatively simple and easy to learn.

In general, no matter what kind of CNC system is used, it must be combined with its own needs to maximize benefits.

Shenchong professional press brake manufacturer always recommends the most suitable CNC controller according to customers’ own conditions, which is in the interests of customers and achieves a win-win situation.