Sheet metal processing is indispensable of mechanical processing, especially in the industries of aviation, home appliances, automobiles, elevators and others, sheet metal parts are all widely used.

As the only single process in sheet metal processing, the bending process or the V groove bending is one of the most important processes. The quality of the bending process will directly affect the forming size and appearance of the product. Therefore, how to ensure the bending size and angle of the workpiece is very important.

On metal V Grooving machine, we slot a V-shaped groove at the position where the metal sheet needs to be bent, and then bend on bending machine as required.

The characteristics of V groove sheet metal bending process mainly include the following three aspects:

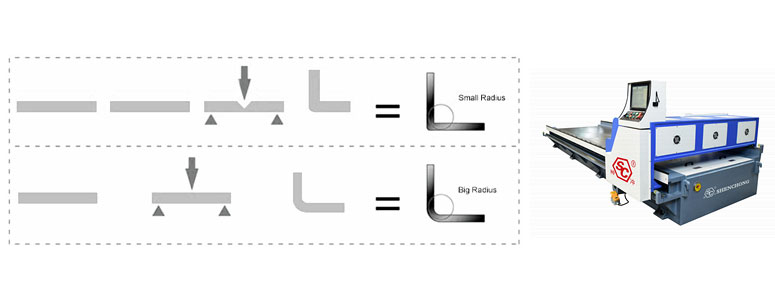

– The workpiece arc radius to be small, no creases or indentation

Aftergrooving the sheet metal, the remaining thickness of the sheet becomes half of the original thickness, or even smaller, so that the workpiece arc radius after the bent can be greatly reduced.

In addition, the sheet metal after grooving, the remaining thicknessis thinner, the deformation force during bending will be reduced accordingly, and will not spread to the unbent area. So after bending, there are no creases on the surface of the workpiece. And the less bending pressure avoid the risk of indentation on the decorative surface.

In this way, small arc radius, no creases or no indentation on the decorative surface, which meet the decoration of high-end places such as hotels, banks, commercial centers, airports, etc.

– Reduced the bending machine force

In the bending process, we need larger bending force when bending more thick plates. After slotting the sheet metal on CNC metal V-Grooving machine, the remaining thickness of the sheet is greatly reduced, so that the bending force required will also be correspondingly reduced, the thick plate bending can be finished on a smaller tonnage press brake machine. This not only reduces the investment in equipment, but also saves energy and space.

– Complex shape workpiece bending and control of bending rebound

The workpiece shown in the figure, which unable to comlete the bend on a general bending machine, but if we slot it on CNC metal V Grooving machine firstly, the workpiece can be completed with some manual bending on the press brake machine.

In addition, the remaining thickness of the plate can be controlled by CNC sheet metal V Grooving machine, which will help to control rebound force and the rebound angle when bending.

For example, If the remaining thickness after grooving is controlled at about 0.03mm on metal V-grooving machine, the rebound angle can be made small, the rebound can be basically ignored.

In sheet metal production, we put the v-groove metal for bending on the grooving machine, and locate it, then input the thickness of the plate for automatic grooving.

When grooving, we need pay attention to two aspects:

– The V groove angle setting

From the bending process and bending experience, we know that the sheet metal has different degrees of springback deformation during bending and forming, which causes the deviation of the bending angle.

When slotting the sheet metal bending V groove size, the groove can be rationalized according to the required bending angle of the workpiece. Generally, the angle of the V-groove is 1-2° larger than the bending angle. For example, when we bend one workpiece to be 90°, the V-groove angle usually will be slotted to 92°, so that the caused bending angle rebound can be easily avoided.

– The V groove depth setting and remaining thickness setting

In the case of a certain plate thickness, the groove depth and the remaining thickness are corresponding values. Usually we set a remaining thickness value, at the base of the requirements of the bending process. Generally, the default value is 0.8mm, and the minimum should not be less than 0.3mm.

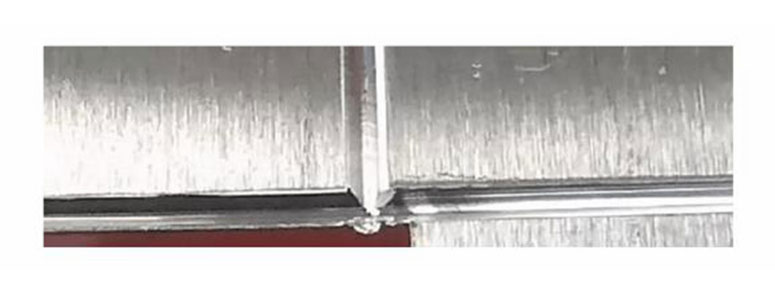

According to the plate thickness, we set the V grooving times and the V grooving depth. Due to the need to control burrs and protect the tools, the grooving depth should not be too large. Usually the depth of the first groove cannot exceed 0.8mm, and it must be carried out in at least two grooving.

For example, for a stainless steel plate thickness of 1.2 mm, the remaining thickness should be 0.5 mm after slotting, the first V grooving depth can be 0.5 mm, and the second V grooving depth will be 0.2mm. After two times of V grooving, the remaining plate depth amount just reached 0.5mm, and the burrs were relatively small, as shown in the below figure:

V groove bending, as a new type of bending process, is the result of market choice. Shenchong has been dedicated to the research and production of sheet metal V-Grooving bending for 20 years, continue to explore and pursue new technology, users can produce more excellent products.