The roll bending machine is a public forging machine that can bend and roll metal plates into cones, spheres, cylinders, or other shapes. This performance is widely used in industries such as manufacturing, boiler steam, chemical engineering, non-metallic construction, and machine building.

Due to the different fields of use, the types of bending machines are also different. From the number of rollers, it can be divided into three roller plate bending machines and four roller plate bending machines. What is the difference between 3-roll and 4-roll bending machines?

Many people feel that the difference between a 3 rollers bending machine and a 4 rollers bending machine is just one more roller, and there is no difference between the others.

Therefore, some people purchase a four roller plate bending machine with the idea of "one more roll, one more effect.". But in fact, this idea is wrong because there is a big difference between the two. As follows:

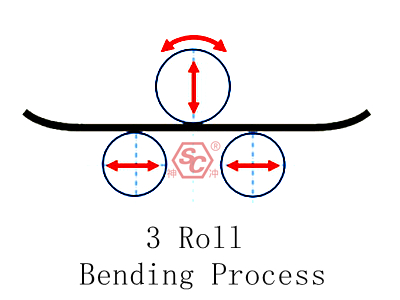

The 3-roll plate rolling machine has three rollers. The 4-roll plate rolling machine has four rollers.

In addition to this most obvious feature, the appearance of the three roller bending machine is relatively simpler. Its focus is on simplicity and practicality.

The 4-roll bending machine is hydraulically controlled, so its appearance is also more exquisite and beautiful. The details were also handled to a higher standard. There are higher requirements for machining accuracy and comfort in use.

Mechanical three-roller plate bending machines are further divided into three-roller symmetric plate bending machines and three-roller asymmetric plate bending machines.

The symmetrical three roller plate rolling machine has one roller on the top and two rollers on the bottom, which are symmetrical. The three roller asymmetric plate rolling machine has two rollers on one side and one roller on the other side, which is asymmetric.

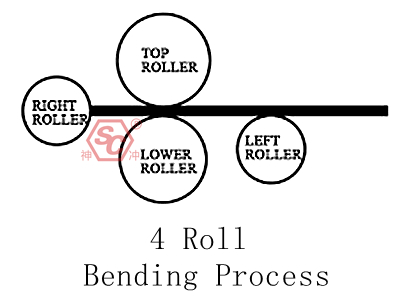

The upper roller of the four roller plate rolling machine is mainly driven and connected to the upper roller through a reducer and a cross slider coupling to provide torque for rolling plates.

The lower roller performs a vertical lifting movement and is obtained through the worm gear (bevel gear) of the speed reducer and the auxiliary screw rod to clamp the plate, which is a mechanical transmission.

A side roller is arranged on both sides of the lower roller and moves obliquely along the rack guide rail, which is driven by a screw, worm, and worm gear (or bevel gear).

The 4-roll plate rolling machine has two rollers on the top and two rollers on the bottom. All four working rollers adopt dynamic bearings. However, this difference in rollers results in a significant difference in the walking mechanism between a three roller plate bending machine and a four roller plate bending machine.

The three roller plate rolling machine can roll metal plates into a circular or arc shape.

Its rollers move vertically up and down in a symmetrical position in the center of the two lower rollers, and are obtained through a screw and mother screw worm drive. The two lower rollers rotate and are driven by an electric motor.

The output gear of the reducer meshes with the lower roller gear to provide torque for the rolled plate. The end of the plate needs to be pre bent with the aid of other equipment.

The four rolle bending machine is suitable for bending and forming metal plates. It can roll circular, arc shaped, and tapered workpieces within a certain range, and has the function of pre bending the plate ends. The remaining straight edges are small, allowing for rough leveling of the metal plate.

The 3-roll bending machine is simply controlled by a button. The four roller plate bending machine has a touch screen and a CNC system that can be programmed.

Numerical control of 4-roller plate bending machine. One-time roll forming. The touch screen supports visual input, editing work steps, and storing 500 sets of data.

EPS electronic balance system: ensure that the roller movement is parallel within 0.15mm.

All movements of the four roller rolling plate are driven by hydraulic pressure. The rollers on both sides move in a straight line within the guide rail, achieving precise rolling accuracy.

Solid overall support to meet the needs of medium and large rolling. The entire frame is annealed to eliminate stress and never deform. The roller shaft is forged by a complete machine, and has undergone a hardening process of quenching, tempering, and quenching.

Compatible with manual and automatic modes. Support man-machine dialogue, fault self-diagnosis, intelligent judgment of operational errors, and drum shaped roller shafts. The rolling roundness is good. High straightness.

The 3-roller plate bending machine is a manual unloading machine that requires manual unloading of the processed workpiece.

The 4-roller plate bending machine is controlled by buttons, making unloading convenient and fast. Compared to the three roller plate bending machine, it is also much easier to arrange.

Three-roller asymmetric plate bending machine: the upper roller is mainly driven, and the lower roller moves vertically to clamp the plate. The lower roller gear meshes with the upper roller gear and serves as the main transmission. The side roller performs tilting and lifting movement, with dual functions of pre bending and rounding.

Three-roller symmetrical plate rolling machine: the upper roller performs vertical lifting movement at the center symmetrical position of the two lower rollers, and is obtained through screw and mother screw worm transmission. The two lower rollers rotate and engage with the lower roller gear through the output gear of the reducer to provide torque for the rolled plate. They work on the same principle, using the three-point rounding principle for rolling with different radii.

However, the straightness and roundness of the pre bending of the 4-roll bending machine are better than those of the three roller bending machine.

Most 3-roller bending rolls are mechanical, but there are also hydraulic types. But all four roller bending machines are hydraulic bending machines.

The structural form of the mechanical three-roller symmetrical plate bending machine is a three-roller symmetrical type. The upper roller moves vertically in a symmetrical position between the two lower rollers through bevel gear transmission, and the secondary gear of the main reducer drives the two lower roller gears to mesh and rotate to provide torque for rolling the plate.

A flat plastic metal plate passes between the three working rollers (two lower rollers and one upper roller) of the plate rolling machine, and through the downward pressure of the upper roller and the rotational motion of the lower roller, the metal plate undergoes multiple passes of continuous bending, resulting in permanent plastic deformation. So as to be rolled into the desired cylinder, cone, or part thereof.

The disadvantage of the mechanical 3-roll bending machine is that the end of the plate needs to be pre bent with the help of other equipment.

The structural form of the hydraulic three roller symmetrical plate bending machine is three roller symmetrical type. The upper roller acts on the piston through the hydraulic oil in the hydraulic cylinder at the central symmetric position of the two lower rollers for vertical lifting and lowering movement. The final gear of the main reducer drives the two lower roller gears to mesh and rotate, providing torque for the rolled plate.

The disadvantage of the hydraulic three roller symmetrical plate bending machine is that the end of the plate needs to be pre bent with the help of other equipment.

The hydraulic three roller symmetrical plate bending machine is suitable for large plate bending machines with a thickness of more than 50mm. A row of fixed idlers is added to the lower part of the two lower rollers to shorten the span between the two lower rollers, thereby improving the accuracy of the rolled workpiece and the overall performance of the machine.

The 4-roll bending machine is a hydraulic plate bending machine. The upper roller is mainly driven and meshed with the upper roller gear through the output gear of the reducer to provide torque for rolling plates.

The lower roller performs a vertical lifting motion, which is obtained by the action of hydraulic oil in the hydraulic cylinder on the piston to clamp the plate, and is hydraulically driven. A side roller is arranged on both sides of the lower roller and moves obliquely along the rack guide rail, which is driven by a screw rod, a mother screw, a worm gear, and a worm gear.

The advantage of this machine is that pre bending and rounding of plate ends can be performed on the same equipment.

Due to the fact that most 3-roller bending machines are mechanical, the processing efficiency of the motor is also low. Moreover, many processes require manual coordination, so the work efficiency will be relatively low.

Due to the fact that the 4-roller bending machine is a hydraulic plate bending machine and is numerically controlled, the machining efficiency of the motor is high. Therefore, the overall work efficiency is also much higher. The output rate of the workpiece is also much higher than that of the three-roller plate bending machine.

The processing accuracy of the 3 roller bending machine is average, which can meet the basic needs of most factories.

The 4 roller plate bending machine has higher machining accuracy, and can also process special shaped workpieces such as cones.

There are many models of plate bending machines, and the structural performance of each type of product varies considerably. Users who want to purchase a bending machine must fully understand the differences between these various models. Don't buy with the wrong perception. Otherwise, the purchased bending machine not only does not meet your work needs and cannot fully exert its effectiveness, but also adds a lot of trouble to your work.

Under the same model, the price of a three roller plate bending machine is lower than that of a four roller plate bending machine. Because the accuracy and efficiency of the three roller plate bending machine are lower than those of the four roller plate bending machine.

If the frequency of use of the machine is not high, and the accuracy requirements for the workpiece are not high, a lower priced 3-roller plate rolling machine can be selected. However, if there are higher requirements for the product, it is more recommended to use a 4-roller plate rolling machine with good performance.