The DELEM DA 58T cnc press brake controllers offer modern compact and versatile solutions for powerful economic press brake applications. DA 58T graphical programming and numerical programming solutions based on state-of-the-art press brake control enable optimal flexibility. It's the easiest CNC programming based on the Delem graphical touch screen user interface including automatic bend sequence calculation and collision detection. It can provide a modern compact and versatile solution for powerful economic press brake applications.

Wuxi Shenchong CNC press brake machine can be optionally equipped with a DA-58T controller. In addition, we can also configure DA 66T, DA 69T, ESA controllers, ELGO controllers, and Cybelec controllers according to your needs. You can further communicate with us about the specific configuration requirements for the CNC system of the bending machine.

Next, let's take a look at the DA58T CNC system so that you can choose the appropriate controller when purchasing a press brake.

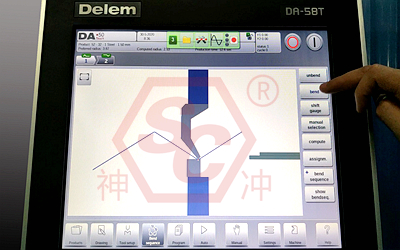

The DA-58T CNC press brake controller is a state-of-the-art complete 2D graphical control solution for synchronized press brakes. Offering easiest CNC programming based on the Delem graphical touch screen user interface including automatic bend sequence calculation and collision detection.

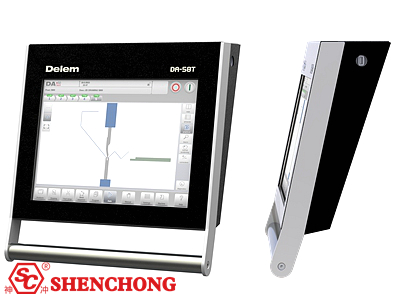

Its 15" high resolution colour TFT, with industrial grade multi touch screen technology, gives access to the proven Delem user-interface. It enables direct navigation between product programming and actual production. Functions are directly located where needed, offering optimised ergonomics throughout the entire application.

Press Brake Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence. CNC programs are generated with a single touch. You are immediately ready to make the first part since all axes positions are automatically computed and the bend sequence has been simulated with machine and tools in real scale. The production mode of the DA-58T CNC controller helps the operator in graphically simulating the bend process of the product, guiding him during the press brake operation.

Highly effective control algorithms optimise the machine cycle and minimise set-up time. This makes using press brakes easier, more efficient and more versatile than ever. The OEM-panel located above the screen, reserved for machine functions and OEM-application switches, is integrated in the design and can be used depending the required application.

Compact 4-axes colour graphical CNC system for press brakes

- 2D graphical touch screen programming

- 15" high resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

The new generation DA-50T series offers easiest CNC programming based on the Delem graphical touch screen user interface. The standard machine control functions are Y1-Y2 and X axis. A second back gauge axis can be used as R or Z axis. Also crowning control is standard on board. The DA 58T cnc press brake controller offers 2D programming including automatic bend sequence calculation and collision detection.

Standard | |||

Display | Colour LCD display | Display | Colour LCD display |

Type | 15" TFT, high brightness | Type | 15" TFT, high brightness |

Resolution | 1024 x 768 pixels, 32 bit colour | Resolution | 1024 x 768 pixels, 32 bit colour |

Touch sensor | Full touch screen control (PCT-touch) | Touch sensor | Full touch screen control (PCT-touch) |

Backlight | LED | Backlight | LED |

Storage capacity | 1 GB | Storage capacity | 1 GB |

Product and tools memory | 256MB | Product and tools memory | 256MB |

Exchangeable memory | USB flash memory drive | Exchangeable memory | USB flash memory drive |

Options | |

Networking | Standard Windows® networking |

Tandem capability | TandemLink |

- Multi touch industrial touch screen

- Instant Shut Off

- Power supply: 24V

- Opto-isolated digital I/O

- Integrated valve amplifier Y1, Y2

- Encoder inputs (single/diff.5V/12V)

- RS232 port

- Network interface

- USB port

- Servo control

- Unipolar / frequency inverter control

- Pressure valve control

- Proportional valve control

- Crowning control

- Multiple digital function outputs

- Tandem operation (dual)

- Housing 405x388x122 mm

- Design, aluminium edge

- IP54

- Alphanumerical product naming

- Real-scale product programming and visualisation

- Automatic bend sequence calculation

- Easy graphical bend sequence swap and move

- Hemmed products programming

- Radius programming (bumping)

- One page programming table

- Graphical product and tool selection

- Programmable material properties

- Programmable axis speed

- Free material programming

- Product & tool search filter

- Millimetres/Inches, kN/Ton selection

- Stock counter

- Tool library 30 punches / 60 dies

- Alphanumeric tool identification

- Free graphical tool programming

- Hemming tools

- Radius tools

- Tooling safety zones

- Press force

- Crowning adjustment

- Developed length

- Bottoming force

- Hemming force

- Auto bumping calculation

- Bend allowance table

- Learned angle correction database

- 'Teach-in' on all axes

- Operator selectable dialogue languages

- Integrated help function

- Error messaging system

- Diagnostic program

- Remote Assistance option

- Machine time + stroke counter

- On board Analysis Tool

- Sequencer functionality (PLC)

- Safety PLC interfacing

Fit for the purpose, enabling lean machine design with all important functionality directly at hand.

Delem touch navigation offers proven user friendliness and consistency ensuring user-efficiency.

Excellent press brake machine behavior enabling smooth and fast bending at highest reliability.

Machine functions and integration of partner systems, not compromising compatibility and performance.

Besides DA58T CNC system, there are DELEM DA66T, DA69T, ESA S630, ESA S640, ESA 650W, Cybelec Touch 12, Cybelec ModEva Pac, Cybelec VT19, ELGO controllers and so on that can be used in CNC bending machines.

If you want to know how to select a CNC press brake machine system, please click here: How to Choose CNC Controller for Press Brake: Ultimate Solution