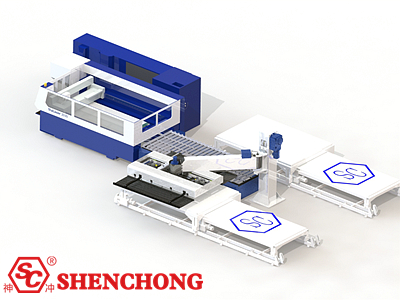

Loading and unloading machine is a rectangular coordinate robot used for auto loading & unloading of CNC machine tools. In industrial applications, it is an automatic device that can achieve automatic control, repeatable programming, multi-function, multiple degrees of freedom, and a spatial right angle relationship between degrees of freedom of motion.

The combination of loading and unloading robots and CNC machine tools can achieve automatic workpiece grabbing, loading, unloading, shifting, turning, and sequence transfer processing in all process processes. This can greatly save labor costs and improve production efficiency.

The automatic loading & unloading equipment of CNC machine tools is coordinated and controlled by a PLC programmable logic controller, and is coordinated and processed by various hydraulic cylinders and air cylinders.

It is responsible for moving the workpiece to be processed on the loading and unloading rails of the manipulator into the machine tool. After finishing machining, it takes the processed workpiece out of the machine tool and returns to the upper and lower material rails.

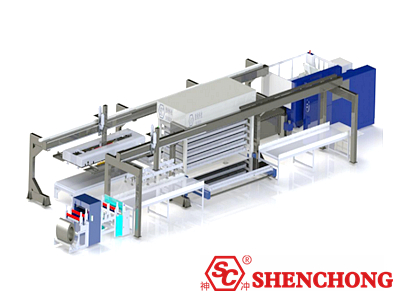

The entire automatic loading and unloading process includes five major parts: workpiece conveying, manipulator picking up, loading and unloading, manipulator feeding, and sending parts to the next process.

The part of workpiece conveying and delivering parts to the next process is executed in parallel with other parts and CNC machining. The picking and feeding parts of the truss type manipulator are carried out simultaneously with the CNC machining.

There are horizontal conveying, inclined conveying, lifting conveying, etc.

- Horizontal conveying can transport different items, and different conveying speeds and forms can be adopted.

- Tilt conveying can adjust the tilt angle. The use of patterned conveyor belts or horizontal baffles improves the stability of the conveyor belt's grip on the workpiece, prevents the workpiece from slipping and falling off, and ensures accurate operation trajectory.

- Lifting and conveying takes up little space, which has a good effect on small cylindrical parts.

When designing a PLC program, if the workpiece to be processed has directionality, the edited PLC program should not only control the rotation and positioning of the workpiece, but also consider the reliability of positioning.

If the positioning is not on time at one time, it is possible to reorient the positioning once or twice to ensure that the cycle does not stop due to accidental errors in workpiece conveying and positioning.

When the workpiece is transported in place, the loading robot is responsible for delivering the workpiece to be processed on the conveyor line to the machine tool. And take out the processed workpiece from the machine tool and put it back to the original loading position.

Its movements include: claw opening and closing, lifting movement, left and right movement. The gripper opening and closing is driven by a cylinder. The lifting movement and the left and right movement are respectively driven by servo motors.

During the process of grasping a workpiece, it is necessary to ensure the positional and angular relationship between the gripper and the workpiece.

First, adjust the alignment of the reference plane on the gripper and the corresponding reference plane on the table to reduce angular error. Then translate the gripper or material table to adjust the position error.

During the loading and unloading process, the manipulator should cooperate with some auxiliary functions of the machine tool. It requires synchronous coordination, stability and reliability.

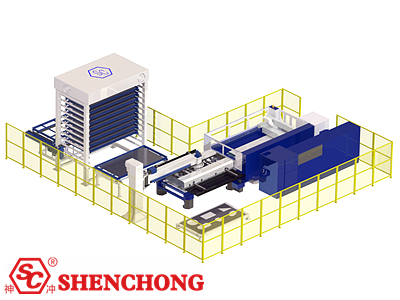

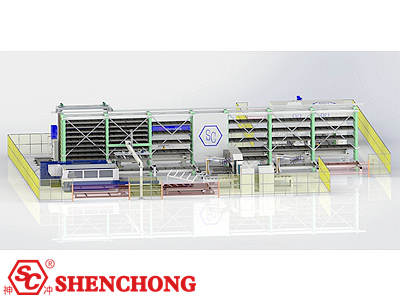

The relative positions of the loading and unloading channels and intelligent storage systems with the work host determine the position and posture of the workpiece in the space before and after loading. This directly affects the coordinate form of automation equipment and robots.

After loading and unloading, the robot must transport the processed workpiece to the feed chute. At this time, feeding takes precedence over picking and loading and unloading, and picking takes precedence over loading and unloading. In this way, it can be ensured that during the entire auto loading & unloading cycle, there will be no grasping of the plate by the gripper.

Loading and unloading is a complete cycle. The loading waiting position must be started and the unloading can only be carried out after the loading is completed. After the completion of blanking, return to the loading waiting position and prepare to execute the next loading and unloading cycle.

If there is a power failure or misoperation during the process, you can only "restore the initial position" and restart at the loading waiting position. Press "Emergency Stop" carefully!

The robot sends the finished workpiece to the material warehouse. And then through conveyor belts and other means. Send the finished workpiece to the next production process.

Installing an automatic loading and unloading machine can replace the conveying device, simplify the workpiece conveying process, make the production line more compact, promote active procedures, and improve labor productivity.

Through practice, it has been confirmed that from an economic perspective, using a feeding manipulator for the production and manufacturing plant can make relatively small changes to the mold, be economical, practical, and relatively fast, with good social and economic benefits.

Auto loading & unloading system plays an important role in industrial automation production. According to production needs, there are several types of robots, such as bending robot, welding robots, handling robots, and loading and unloading robots. What effects can the use of loading and unloading robots bring us?

The loading and unloading machine needs to replace manual coordination based on the process requirements or action requirements of the production equipment. Usually used in machine tools, production lines, and other special loading and unloading.

In the production process, it is easy to achieve automatic loading, unloading, and turnover of workpieces or materials, realizing the automation of the mechanical processing process.

During the machining process, the loading and unloading system generally uses two manipulators, one for loading and the other for unloading. A simpler method is to use two Z axes to achieve the functions of two manipulators. But the results are all the same.

Let's take the application of the above auto loading & unloading system to machine tools as an example to briefly summarize its significance.

The significance of using automatic loading and unloading system for machine tools is to have a relatively strict process flow from workpiece drawings to making qualified workpiece during processing. As long as the processing technology is reasonably arranged, qualified products can be quickly and accurately processed.

The automatic loading and unloading machine is used to realize automatic operation of the processes such as automatic gripping, loading, unloading, clamping, and processing of the workpiece. The accuracy of the positioning of the loading and unloading operations determines the quality of the product. The main purpose of the loading and unloading machine is to deliver the sheet metal into the machine tool. Wait until the processing is complete before taking out the finished product, and then repeat the operation.

- When loading, raw materials are placed in the sheet metal storage warehouse. The plate is positioned and grabbed by a positioning mechanism. Then move the sheet into the machine tool.

- During blanking, the manipulator will move over the machine tool and clamp the processed workpiece. When the robot receives the signal that the clamp is released, it takes out the workpiece and moves it to the designated position, then puts it in.

According to the traditional manual operation method, at least 2 people are required to cooperate with each machine tool for complete production. This kind of processing cycle will be longer, labor waste will be greater, and equipment space consumption will be large. There will also be situations where the quality of the products produced is uneven.

By using a intelligent loading and unloading system, manual labor only needs to place the material in the material storage system, which can be processed for several hours at a time. In this way, one person can take care of more than five machine tools.

Moreover, the auto loading & unloading robots operate the machine tool through preset programs. All processes are carried out in accordance with unified standards, so that the quality of the products produced will not be uneven.

Intelligent Manufacturing Redefine Your Future!

Wuxi Shenchong is devoted to make automation equipment available to everyone, promote production and lead the future into Industry 4.0. Through further development and research of automation technology, Shenchong machines will be more efficient, accurate and future-proof. Our high-quality solutions help you achieve an efficient and sustainable future!