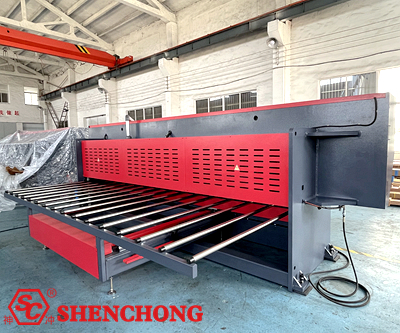

CNC Vertical V Grooving Machine adopts frame structure and high strength bolt connection. The overall rigidity is good and the deformation is small.

- The machine is composed by machine basis, crossbeam, blade shaft, CNC system, hydraulic plate press system, compressed air and coolant system.

- The whole structure is frame vertical design. Whole steel plate integral welding and high-strength bolt connection. Strong resistance.

- Using large tempering furnace to eliminate stress. Good stability.

- High precision ball screw as a power transmission element. High precision, low noise, low power consumption.

- Adjustable movable work surface, make slotting depth accurate for every part.

- Numerical control program design is reasonable, easy to master.

Intelligent Manufacturing Redefine Your Future!

- Suitable for 3-5mm thick plate.

- Used for grooving of special-shaped plates.

- Better for aluminum plate: when placed horizontally, the surface of aluminum plate is easy to be uneven. If you use a horizontal v-groove machine, the aluminum plate is likely to be broken down.

- The price is relatively high, compared with the horizontal model.

In the use of vertical V grooving machine, users need to move the plate. And there are certain requirements for the site and space.

- High stability, strong rigidity and also convenient in usage.

- The CNC control system has several parameter to choose , big in storage and easy in operation.

CNC control system has 3 axis, 3 axis is AC servo motor drive, high in control precision.

- Machine worktable using carbon tool steel. The hardness after quenching reaches HRC55 or more. Wear of the table surface is small and can be changed.

- Has 3-10 cutting structure, greatly improve the cutting working efficiency, and also can promote the cutting quality.

- Use ball-screw and line guide, gear and rack transmission to enhance the machine durability and precision. The repeat positioning accuracy is ±0.03MM.

- CNC system: Japan

- Hydraulic system: Taiwan famous brand

- Frequency converter: Mitsubishi

- Servo motor: Mitsubishi

- Seal ring: VALQUA, Japan

- Motor: SEW

- Air switch : Schneider

- Contactor: Schneider

- Breaker and button: Schneider

- Relay: Schneider

- Blades: KORLOY, Korea

- Linear guide: HINWIN, Taiwan

- Wire I: GUS, Germany

- Suitable for 3-5mm thick plate.

- Used for grooving of special-shaped plates.

- Better for aluminum plate

When placed horizontally, the surface of aluminum plate is easy to be uneven. If you use a horizontal v-groove machine, the aluminum plate is likely to be broken down.

- The price is relatively high, compared with the horizontal model.

- In the use of vertical V grooving machine, users need to move the plate. And there are certain requirements for the site and space.

- Use CNC V Grooving Machine to line and planer v-shaped groove on the position where the metal plate needs to be bent.

- After grooving, you can use the general mold to bending the special closed shape material on the common bending machines.

- The iron plate after grooving is easier to bend. And then, the quality and shape of press brake bending will be better.

- Vertical steel groove machines have a dozen separate pressing plates and more than ten independent clamps for automatic clamping. Plates of all sizes can be processed with smaller energy consumption and higher safety.