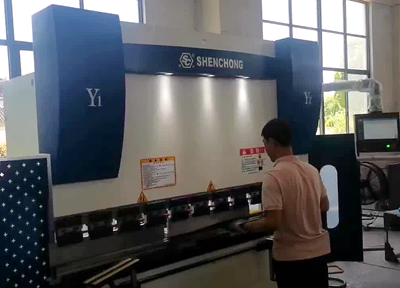

This is SC WEK CNC Hydraulic Press Brake 80Ton 2500mm sent to Machinery Manufacturing Plant. This is a mechanical equipment used for sheet metal processing, mainly used for precise bending operations on sheet metal. The following is a detailed introduction to its main features and functions:

- WEK electro-hydraulic series

- 80Ton 2500mm

- 4+1 axis

- EL15T CNC control system

SC CNC hydraulic press brake 80Ton 2500mm for sale is equipped with an advanced CNC system, which allows the operator to accurately control the bending angle and length through a digital interface. This makes the production process more automated, reduces manual intervention, and improves processing accuracy.

Users can set different bending parameters such as bending angle, bending length, etc. through programming to achieve bending of complex shapes.

The bending machine uses a hydraulic system to provide the required force. The hydraulic system pushes the bending die through the pressure of the hydraulic oil to bend the metal sheet.

The design of the hydraulic system ensures the stability and reliability of the equipment under high pressure.

The equipment is usually welded with high-strength steel, which ensures the stability and durability of the bending machine during work.

The bending machine is equipped with different types of bending dies (such as V-shaped dies) to adapt to various metal sheets and bending requirements.

Some high-end models are equipped with automatic tool setting function, which further improves the bending accuracy.

Modern bending machines are usually equipped with a variety of safety protection devices, such as safety guardrails, emergency stop buttons, etc., to ensure the safety of operators.

SC WEK CNC Hydraulic Press Brake 80Ton 2500mm For Sale is widely used in automobile manufacturing, aerospace, shipbuilding, construction engineering and various metal processing industries, suitable for processing medium thickness metal sheets.

The main advantages of this equipment include high precision, high efficiency and good operational flexibility, which can meet a variety of different processing needs. If you have more specific needs or want to know more details, you can check the technical manual of the equipment or contact the press brake supplier.