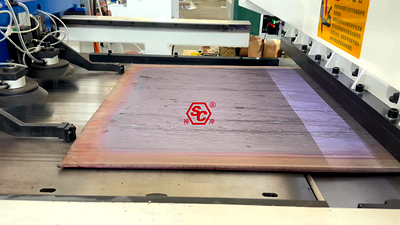

The copper plate fully automatic shearing line cuts the copper plates into strips of 100-150mm×1000mm and stacks them.

The copper plate fully automatic shearing line is a highly efficient automated equipment designed specifically for copper plate processing. It is mainly used to cut large-sized copper plate coils or copper plate sheets into the required size and shape through a shearing process.

The fully automatic shearing line is equipped with an advanced control system, which can automatically perform multiple processes such as loading, unloading, positioning, and shearing, greatly improving production efficiency, reducing manual intervention, and is suitable for mass production.

Modern shearing lines usually use CNC systems (CNC) to accurately control the shearing process, which can ensure the accuracy of the shearing size of the copper plate with minimal error, and is suitable for the manufacture of copper products that require high precision.

The shearing speed of the fully automatic shearing line is much faster than that of manual or semi-automatic equipment, and can achieve continuous high-speed shearing, which can meet the needs of efficient production.

Due to the use of fully automatic control, the shearing line is safer during operation and is equipped with multiple safety protection devices to reduce the risk of operators. In addition, the equipment is designed to be stable and durable, suitable for long-term high-intensity work.

The fully automatic shearing line for copper plates can usually adjust the cutting size according to demand, and is suitable for processing copper plates of different thicknesses and specifications. The equipment can adapt to different copper material widths, thicknesses and material hardness.

Modern shearing lines produce less waste during processing, and the equipment is designed to optimize energy consumption, meeting current environmental protection and energy-saving requirements.

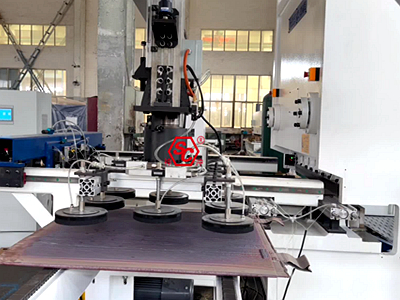

Feeding: The copper plate is fed into the production line through the automatic feeding device.

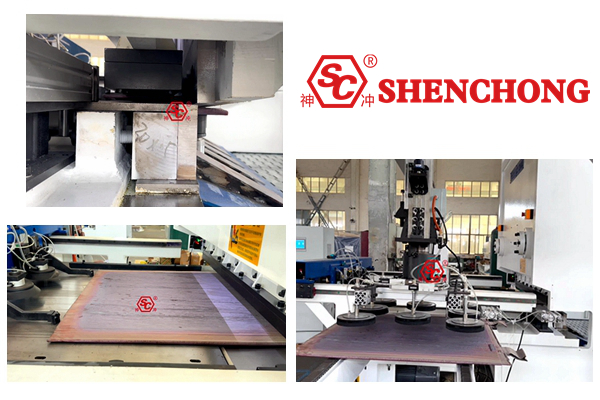

Positioning: The system accurately locates the shearing position of the copper plate.

Cutting: The copper plate is accurately cut according to the set size through the shearing machine.

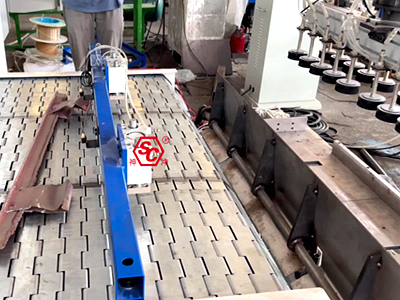

Unloading and collection: The sheared copper plate automatically enters the unloading device, and the finished products and waste are collected by classification.

The copper plate automatic shearing line is widely used in the fields of electricity, electronics, construction, decoration, etc. It is especially suitable for the production of transformer copper cores, copper coils, motor parts, and various copper decorative materials.