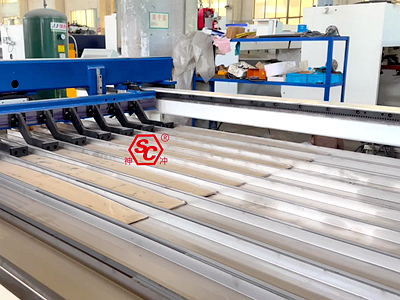

SC nickel plate fully automatic shearing production line for sale is an automated equipment for processing and handling nickel plate materials. It uses an automated process to cut large-sized nickel plates into small-sized plates or strips according to specific specifications, which is suitable for mass production. It is mainly used in industries such as electronics, aviation, and chemicals, where nickel plates used usually require high-precision cutting.

This type of production line generally includes the following parts:

The automatic feeding device can feed the original nickel plate material into the shearing production line to reduce manual operation.

The core equipment is used to accurately cut the nickel plate according to the preset size. The shearing method can be mechanical, hydraulic or CNC control to ensure cutting accuracy.

The cut nickel plate is moved to the next process or collection area through a conveyor belt or other transmission equipment.

The cut nickel plates are automatically arranged or stacked for subsequent processing or packaging.

These automated functions greatly improve production efficiency, reduce errors caused by human operation, and can meet the needs of large-scale production.

The features of the nickel plate fully automatic shearing production line are mainly reflected in the following aspects:

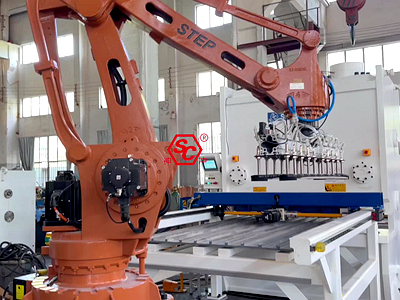

The production line is highly automated, and all links from loading, shearing to unloading, stacking, etc. can be completed automatically, which greatly improves production efficiency and reduces manual intervention.

Adopting advanced shearing technology, combined with the CNC system, it can accurately control the shearing size of the nickel plate, ensure product quality consistency, and is suitable for high-demand applications.

The design takes into account the physical properties of the nickel plate (such as hardness and toughness), so the equipment can ensure that the nickel plate is not damaged during processing, especially suitable for processing thin and high-strength nickel materials.

The plate shearing machine can be flexibly adjusted according to different production needs, suitable for processing nickel plates of various specifications, and meet the size and shape requirements of different products.

Controlled by PLC or industrial computer, it is easy to operate, and can realize the continuous production of multiple batches and nickel plates of different sizes through preset programs. It also has fault detection and alarm functions to ensure the safety and continuity of production.

Automated production lines reduce labor costs, while reducing material waste through precise shearing and improving material utilization.

Some advanced nickel plate shearing production lines also have the characteristics of low energy consumption and low noise, meet environmental protection standards, and reduce carbon emissions and noise pollution during the production process.

This production line is particularly suitable for industries that require a large amount of nickel plate processing, such as battery manufacturing, aerospace, and electronic component production, which can significantly improve production efficiency and product quality.

Click here to know other shearing line:

SC Copper Plate Automatic Shearing Line

SC Steel Plate Shearing Automatic Production Solution

Compared with manual shearing, the fully automatic nickel plate shearing production line has the following significant advantages:

The fully automatic shearing production line can process nickel plates continuously and quickly, greatly improving production efficiency, while manual shearing is usually slow, especially in mass production, where the efficiency is limited.

Automated equipment can operate stably for a long time, reducing downtime or operational delays that may occur during manual shearing.

Fully automatic production lines usually use numerical control (CNC) technology to ensure the accuracy of the size and shape of the cuts. Compared with manual operation, automated equipment can ensure that each piece of nickel plate has consistent quality and size, avoiding errors in manual operation.

Since machine shearing will not be affected by manual fatigue or unstable operation, the quality of the produced nickel plates is more stable and reliable.

Automated equipment requires very little manual operation, and usually only a few people are required to monitor and maintain the equipment, reducing the need for a large amount of labor and reducing labor costs.

Manual shearing requires experienced workers to operate, while fully automatic production lines only require a small amount of training to master basic operations, greatly reducing the reliance on skilled workers.

The shearing operation of nickel plate may have safety hazards such as sharp edges, and manual operation is prone to accidents. Automated equipment can greatly reduce workers' operational risks and reduce work-related injuries.

The production line is equipped with an intelligent detection system and automatic alarm function, which can stop operation in time when problems occur to avoid accidents.

The automatic shearing production line can more accurately control the utilization rate of materials and reduce the waste of materials during the shearing process. When cutting manually, material waste or unnecessary loss may occur due to misoperation or inaccuracy.

Automated equipment can be quickly adjusted to adapt to the production of nickel plates of different specifications and shapes. It has strong flexibility and is suitable for customized needs. Manual shearing is less efficient and inconvenient when handling diverse products.

The design of modern automatic shearing equipment focuses on reducing energy consumption. Compared with manual operation, it is more energy-saving and environmentally friendly, and reduces carbon emissions.

Automated equipment is usually designed to be quieter and more friendly to the working environment, while manual operation, especially large-scale shearing operations, is noisier.

Fully automatic production lines can record the production data of each batch through the control system to facilitate traceability and quality monitoring, while manual shearing usually cannot provide accurate recording and data analysis support.

These advantages make the fully automatic nickel plate shearing production line far exceed manual shearing in terms of production efficiency, quality control and operating costs. It is an ideal choice for modern manufacturing, especially large-scale nickel plate processing.