When it comes to workpiece deburring, let's first understand what burrs are. Burrs refer to extremely fine microscopic metal particles formed on the workpiece surface. They are residual chips or extremely fine microscopic metal particles formed during metal casting, grinding, cutting, milling and other similar cutting processes.

The generation of burrs varies with different processing methods. According to different processing methods, burrs can be roughly divided into:

Casting burrs are excess materials generated at the joints of the casting mold or the root of the gate. The size of casting burrs is generally expressed in millimeters.

Forging burrs are generated at the joints of the metal mold due to the plastic deformation of the forging material.

Electric welding burrs are burrs where the filler at the weld protrudes on the surface of the part. Gas welding burrs are slag overflowing from the incision when the gas is cut off.

During stamping, burrs are generated due to the gap between the punch on the die and the lower die, or the gap between the tools at the incision and the wear of the die.

The shape of stamping burrs varies according to the material of the plate, the thickness of the plate, the gap between the upper and lower dies, and the shape of the stamped part.

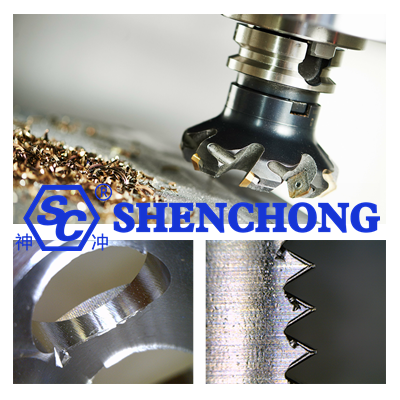

Machining methods such as turning, milling, planing, grinding, drilling, and reaming can also generate burrs. The burrs produced by various processing methods have different shapes depending on the tool and process parameters.

Like casting burrs, these are burrs produced at the joints of plastic molds.

Because of the gap between the molds, burrs are generated. At present, the molds cannot be perfectly combined, so it is difficult to completely avoid the generation of burrs.

However, metal materials are developing towards high hardness, high strength and high toughness, and there are more and more complex and various integral components in mechanical products. The difficulty of removing burrs is also increasing.

With the development of science and technology, the performance of our products is constantly improving, and the requirements for product quality are becoming more and more stringent, and it is more and more important to remove the burrs of workpieces.

The appearance of burrs not only affects the appearance of the product, but also greatly reduces the quality standards of metal workpieces, and affects the assembly, performance and life of the product. Therefore, it is necessary to try to choose good cutting tools during the processing to prevent burrs.

In order to remove burrs, in addition to choosing good tools to avoid, secondary deburring operations are usually required. The three deburring and edge finishing of precision parts may account for 30% of the cost of the finished parts. In addition, secondary finishing operations are difficult to automate, so burrs really become a very difficult problem.

Traditional manual deburring operations are difficult to meet the above-mentioned development requirements for deburring, and various mechanized and automated deburring technologies and processes have emerged.

Next, we will introduce the following workpiece deburring methods:

Die deburring uses the method of making a die and a punch press to remove burrs. Die deburring requires a certain amount of rough die and fine die production costs. It may also be necessary to make a shaping die. The module may need to be replaced for a long time.

Die deburring is suitable for products with simple parting surfaces. The efficiency and effect of this burr are better than manual methods.

Grinding deburring is a method of removing burrs by vibration, sandblasting, rollers, etc. It is also widely used by companies.

The problem with grinding deburring is that sometimes the removal is not very clean. Subsequent manual processing or other methods of deburring may be required. This method is suitable for small products with large batches.

High-temperature deburring is also called thermal deburring and thermal explosion deburring. This is a method of passing some flammable gas into a furnace, and then through the action of some media and conditions, the gas explodes instantly, and the energy generated by the explosion is used to dissolve and remove burrs.

The equipment required for this method is expensive, usually reaching more than RMB 1 million, and the requirements for operating technology are also very high. The efficiency of removing burrs is low, and it can also cause side effects such as rust and deformation. Thermal explosion deburring is mainly used in some high-precision parts fields, such as precision parts such as automobiles and aerospace.

This is a method of using a sudden drop in temperature to make the burrs brittle quickly, and then ejecting projectiles to remove the burrs.

Frozen deburring is suitable for products with small burr wall thickness and small workpieces, and the price of the whole set of equipment is not low.

The chemical deburring method is a process of automatically and selectively removing burrs from parts made of metal materials using the principle of electrochemical reaction.

It is suitable for those internal burrs that are difficult to remove, especially for removing fine burrs on products such as pump bodies and valve bodies.

This is to remove burrs on workpieces using an engraving machine. The price of this set of equipment is not very expensive, and it is suitable for removing burrs with simple spatial structure, simple position and regularity.

This is a method of removing burrs from metal parts using electrolysis. The tool cathode (usually brass) is fixedly placed near the burred part of the workpiece. There is a certain gap between the two. During processing, the tool cathode is connected to the negative pole of the DC power supply, and the workpiece is connected to the positive pole of the DC power supply. Let the low-voltage electrolyte flow between the workpiece and the cathode. After the DC power supply is turned on, the burrs are removed by anode dissolution and carried away by the electrolyte.

Used to remove burrs from hidden cross holes in parts or parts with complex shapes. High efficiency. It usually takes only a few seconds to tens of seconds. Suitable for deburring gears, connecting rods, valve bodies and crankshaft oil passage openings, as well as rounding of sharp corners.

The vicinity of the burrs on the parts is also affected by electrolysis. The surface will lose its original gloss and even affect the dimensional accuracy. The electrolyte is corrosive, and cleaning and rust prevention treatment are required after deburring.

The propagation of ultrasonic waves can also generate instantaneous high pressure, which can be used to remove burrs on parts. This method has high precision and is mainly used to remove some microscopic burrs that can only be observed through a microscope.

The instantaneous impact force of water is used to remove burrs and flash generated after processing, and the purpose of cleaning can be achieved at the same time. And it is divided into two types: workpiece moving type and nozzle moving type.

Low cost, suitable for deburring and cleaning of simple valve bodies. Its disadvantage is that the fit between the nozzle and the valve body is not ideal. The burr removal effect of the cross hole and inclined hole inside the valve body is not good.

The distance between the nozzle and the burr generating part of the valve body can be effectively adjusted through CNC control, which effectively corresponds to the burrs of the cross holes, oblique holes and blind holes inside the valve body. However, due to the high cost of this equipment.

Advantages: good removal effect and fast speed.

Disadvantages: simple equipment is not ideal. Ideal equipment is not cheap.

Mechatronic devices comprehensively use the latest research results of multiple disciplines such as machinery and precision machinery, microelectronics and computers, automatic control and drive, sensors and information processing, and artificial intelligence. Typical parts that can be processed: aluminum wheel hub, inverter housing, synchronizer housing, synchronizer gear hub, bearing cover, cylinder block, valve body, valve cover, output shaft, engine gear, etc.

Advantages: medium cost. Good effect and high precision. High efficiency.

Disadvantages: This technology is in the development stage and has not yet reached the level of popularization. And it requires very accurate data support.

Magnetic deburring uses a unique magnetic field distribution to produce a strong and stable magnetic induction effect, so that the magnetic steel needle and the workpiece are fully ground in all directions and at multiple angles to achieve the effect of quickly removing burrs.

It has special effects on complex shapes, porous gaps, internal and external threads, etc.

For products with inherent magnetism, it is easy to destroy the magnetism of the product itself, so use it with caution.

Manual deburring is also used by most small manufacturers at present. Most of them are small burrs, and the burr removal rate requirement is not high, as long as there are no burrs.

The tools used for manual deburring are files, scrapers, sandpaper, etc. that were used in the past. Now the main tool used is a trimming knife.

Flexible manual operation. Burrs can be removed from different parts of the workpiece by replacing different tools.

Expensive labor costs. Low efficiency. It is not easy to remove some cross holes and complex workpieces.

This method is not much different from manual deburring. It's just that the tools used are different.

Manual deburring uses cold tools to deburr. Manual tool deburring mainly uses some equipment. For example, tools such as grinders and electric drills, combined with milling cutters, drill bits, grinding heads and other materials, can also achieve deburring and chamfering. This method can complete the deburring of most workpieces through different equipment.

Advantages: high flexibility, can adapt to the grinding of most workpiece environments.

Disadvantages: slow speed, easy to cause certain damage to the workpiece.

During the metal cutting process, the burrs generated by various processing methods are of different sizes and shapes. In process design, we should try to choose processing methods that generate smaller burrs. For example, when processing a plane, down milling will be better than reverse milling.

When arranging the processing sequence of parts, we should try to arrange the process that generates larger burrs in the front. And arrange the process that generates smaller burrs in the back. Use the processing of the back process to remove the burrs generated by the front process.

According to the angular effect of burrs, during metal cutting, the outlet should be located at the part with larger angularity of the part to reduce the generation of burrs. At the same time, it should also be noted that the outlet should be located at the part where burrs are easily removed to reduce the cost of workpiece deburring.

During the cutting process of parts, any processing method that produces larger chips will generate larger burrs.

When large chips are generated, the cutting resistance increases, the cutting heat increases, the tool wear increases, the durability decreases, and the plastic deformation of the workpiece material also increases, which makes the generated burrs larger.

Therefore, when machining parts, it is generally necessary to reduce the cutting depth and the amount of cutting to reduce the generation of burrs, especially for the precision machining of parts.

The heat treatment process is reasonably arranged at different stages of the machining process to change the physical and mechanical properties of the workpiece material such as hardness and elongation, which can reduce the burrs generated by the parts during the machining process.

For example: when producing batches of parts, the machining of the retaining ring groove of shaft parts, if the forming grinding wheel is used to grind it out once after heat treatment, the burrs generated will be more than the process of turning and then heat treatment.

During the cutting process of parts, various accessories can be used at the cutting edge of the parts, such as auxiliary supports, mandrels or low-melting-point alloy fillers. It is used to improve the rigidity of the cutting edge of the machined parts, reduce the cutting deformation, and thus reduce the generation of burrs at the cutting edge.

During the processing, burrs are inevitable, so it is best to solve the burr problem from a technological perspective to avoid excessive manual intervention.

Case Show:

Ireland - Metal Deburring Edge Rounding And Finsihing Machine