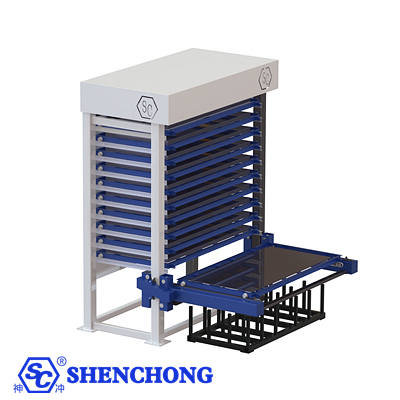

We produced a set of 3015 sheet metal intelligent storage system to Australia. This is a very popular series in the sheet metal storage warehouse.

3015 sheet metal materials usually refer to sheet metal plates with a size of 3000 mm × 1500 mm. Sheet metal materials are metal plates processed by cutting, bending, punching, welding and other processes, and are widely used in manufacturing, construction, automotive industry and other fields. Specific materials may include stainless steel, aluminum alloy, cold-rolled steel plate, galvanized plate, etc. The Shenchong 3015 sheet metal storage system is designed for the automated storage management, handling, transportation and production processing of such sheets.

Next, Wuxi Shenchong Automation Manufacturer will introduce the functions and features of 3015 sheet metal intelligent warehouse to you.

The sheet metal intelligent material warehouse storage is an efficient and automated storage management system specifically for the sheet metal processing industry. It combines information technology, automated control technology, and Internet of Things technology to optimize the storage, management, and distribution process of sheet metal materials.

Sheet metal automated warehousing is an efficient warehousing solution designed specifically for the sheet metal processing industry, using automation technology to manage and store sheet metal materials and finished products. The system integrates automation equipment and software systems to achieve efficient storage, handling and management of sheet metal materials, thereby improving production efficiency, optimizing space utilization, and ensuring the accuracy of material management.

3015 sheet metal automated storage system is an advanced storage solution designed specifically for sheet metal processing companies to improve storage efficiency, reduce labor costs, optimize space utilization, and ensure the accuracy of material management.

The warehouse rack is composed of high-strength steel structure and can carry a large amount of sheet metal materials. The warehouse rack can be designed into a multi-layer structure according to needs to make full use of vertical space.

It includes automated stackers, automated conveyors, etc. These equipment can quickly and accurately transport sheet metal materials to designated locations.

This consists of advanced PLC (programmable logic controller) and computer control system. The control system is responsible for managing and coordinating the operation of the entire storage system, including the warehousing, outbound and inventory management of materials.

Equipped with cameras and sensors, it monitors the operating status of the storage system in real time to ensure safe and efficient operation of the equipment.

A dedicated software system is used to manage and track the inventory status of materials, generate reports and analyze data, and support remote operation and monitoring.

The following are some key features of the 3015 sheet metal storage system.

Automated storage and retrieval of sheet metal materials is achieved through automated equipment (such as automated storage and retrieval machines, stackers, etc.), reducing manual operations and improving efficiency.

The use of RFID tags, barcodes and other technologies for material identification and tracking realizes intelligent management of materials and ensures the accuracy and real-time nature of inventory.

Using stereoscopic warehouse technology, vertical space can be fully utilized to increase storage capacity and optimize space utilization.

Through intelligent algorithms and scheduling systems, the distribution path and time of materials are optimized, distribution efficiency is improved, and waiting time is reduced.

Through data collection and analysis, the storage system can be monitored and optimized in real time, operational efficiency can be improved, and decision making can be supported.

The system can be integrated with the company's ERP (Enterprise Resource Planning) system, MES (Manufacturing Execution System) and other information systems to achieve information management of the entire process.

Through these functions, the sheet metal intelligent warehouse can significantly improve the production efficiency of sheet metal processing companies, reduce operating costs, and improve the accuracy and reliability of inventory management.

SHENCHOGN 3015 Sheet Metal Intelligent Storage System has the following features.

- Automated storage and retrieval equipment: Use automated storage and retrieval machines, stackers and other equipment to realize automated storage and retrieval of sheet metal materials and reduce manual intervention.

- Automated transportation: Equipped with automatic guided vehicles (AGVs) or conveying systems to realize automated transportation of materials within the warehouse.

- Internet of Things technology: Use RFID tags, barcodes and other Internet of Things technologies to identify and track materials and realize intelligent management.

- Real-time monitoring: Through sensors and monitoring systems, real-time monitoring of inventory and equipment operation status in the warehouse.

- Stereoscopic warehouse: Adopt multi-layer shelf design to make full use of vertical space and increase storage capacity.

- Dense storage: By optimizing shelf layout and storage strategy, high-density storage is achieved to improve space utilization.

- Intelligent scheduling: Through intelligent algorithms and scheduling systems, optimize the distribution path and time of materials and improve distribution efficiency.

- Quick response: The system can quickly respond to production needs, dispatch and distribute materials in time, and reduce waiting time.

- Data collection and analysis: Through the collection and analysis of inventory data and equipment data, the warehouse system can be monitored and optimized in real time.

- Decision support: Based on the results of data analysis, support management decisions and optimize warehousing and production processes.

- ERP/MES integration: The system can be integrated with the company's ERP (Enterprise Resource Planning) system, MES (Manufacturing Execution System), etc. to achieve information management of the entire process.

- Open interface: Provide an open API interface to support seamless docking with other systems.

- Safety protection: Equipped with safety protection devices such as anti-collision, fire prevention, and anti-theft to ensure the safe operation of the warehouse.

- Fault warning: With fault detection and warning functions, it can detect and handle equipment failures in time and reduce downtime.

- Green design: Use energy-saving equipment and optimized design to reduce energy consumption and reduce environmental impact.

- Intelligent control: Through the intelligent control system, the equipment operation status is optimized and energy is further saved.

These features enable the 3015 sheet metal intelligent storage system to significantly improve the efficiency of storage management, reduce costs, and improve the reliability and flexibility of overall operations.

The sheet metal automated warehousing system has the following advantages.

- Automated operation: Reduce manual operation, achieve efficient storage and transportation through automated equipment (such as automatic storage and retrieval machines, AGV, etc.), and greatly improve work efficiency.

- Quick response: The system can quickly respond to production needs, dispatch and distribute materials in a timely manner, and shorten the production cycle.

- Reduce labor costs: Reduce dependence on labor, reduce labor costs, and reduce losses caused by human errors.

- Optimize inventory management: Through precise inventory management, reduce inventory backlogs and waste, and reduce storage costs.

- Stereoscopic warehouse: Make full use of vertical space, achieve high-density storage through multi-layer shelf design, and maximize warehouse capacity.

- Intelligent layout: Optimize warehouse layout and improve space utilization efficiency.

- Safety protection: The system is equipped with a variety of safety protection devices, such as anti-collision, fire protection, and anti-theft, to ensure warehouse safety.

- Reduce the risk of accidents: Automated equipment reduces manual operations and reduces the risk of accidents caused by human errors.

- Accurate tracking: Through RFID tags, barcodes and other technologies, accurate tracking and management of materials are achieved to ensure the accuracy of inventory information.

- Real-time monitoring: Real-time monitoring of inventory status and equipment operation to ensure efficient and stable operation of the system.

- System integration: Seamless integration with enterprise ERP and MES systems to achieve full-process information management and improve the flexibility of overall operations.

- Rapid adjustment: According to changes in production demand, the system can quickly adjust and optimize warehousing and distribution strategies.

- Data analysis: Through the collection and analysis of warehousing data, detailed reports and data support are provided to help management make more scientific decisions.

- Optimize operations: Based on data analysis results, continuously optimize warehousing and logistics processes to improve overall operational efficiency.

- Energy-saving equipment: Use energy-saving equipment and optimized design to reduce energy consumption and reduce environmental impact.

- Intelligent control: The intelligent control system optimizes the equipment operation status, further saves energy and reduces operating costs.

Automated systems can optimize the use of materials and reduce waste through precise cutting and processing. This not only reduces material costs, but also promotes environmental protection and sustainable development. Automated warehousing systems also improve the utilization of warehouse space, allowing companies to manage inventory and materials more efficiently.

In summary, the SHENCHONG 3015 sheet metal intelligent storage system can not only significantly improve the company's production efficiency and management level, but also reduce costs, improve safety and flexibility, which is of great significance to the long-term development of the company.

Case Show:

Australia Sheet Metal Intelligent Storage System For Sale

Laser Cutting Automatic Production Case: Sheet Metal Storage System With 2 Laser Cutting Machines

Sheet Metal Flexible Line Cooperated by Shenchong and Zhenhua Heavy Industries