Rolling machine tools are essential equipment for occupations such as stainless steel products, decoration, packaging, metallurgy, airplanes, cars, ships, containers and appearances.

When the 4-roll bending machine is working, the direction of the upper roller is fixed and the lower roller moves upward to clamp the steel plate.

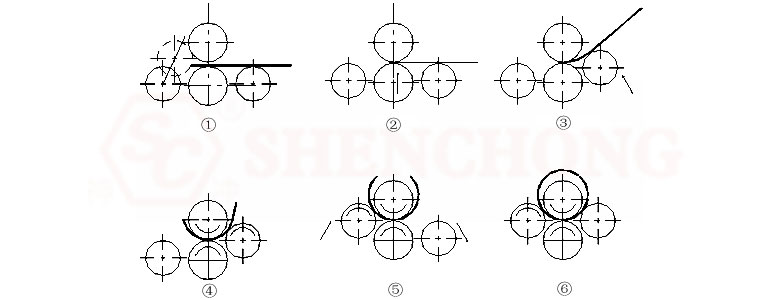

The rollers on both sides move in a straight line or arc to move closer to the rollers to adjust the curvature of the reel. The rollers of the roller coiling machine have different movement modes, but the principles of the work are the same. They all use the principle of three-point fixed circle to roll different sections.

However, the pre-bending straight edge and roundness of the 4 roller bending machine are better than those of the three-roller. In the same period of time, the processing power of the 4 roller plate bending machine is twice that of the three-roller bending machine.

According to the principle of three points into a circle, the use of relative orientation change and rotational movement to make the plate occur. The plate rolling machine is a general equipment for bending the metal plate into cylindrical, arc or other size work pieces.

The 4 roll bending machine is mainly planned for wind power towers. It can be used for the production and processing of various types of wind power towers, as well as shipbuilding, petrochemical, aviation, hydropower, decoration, boiler and motor manufacturing and other industrial fields.

It has been widely used, and it is expected that the metal sheet can be rolled into various parts such as cylindrical, conical and curved plates.

The plate rolling machine is a kind of public forging machinery and equipment that can bend non-metallic plates into cones, spheres, cylinders or other shapes.

This performance is used in a wide range of industries, boiler steam, chemical, non-metallic construction and machine building and other businesses.

The four-roller plate rolling machine is suitable for the bending and forming of metal plates. It can roll round, arc and tapered work pieces within a certain range.

It has the function of pre-bending the end of the plate, with small remaining straight edges, high work efficiency, The sheet metal can be roughly leveled on this machine.

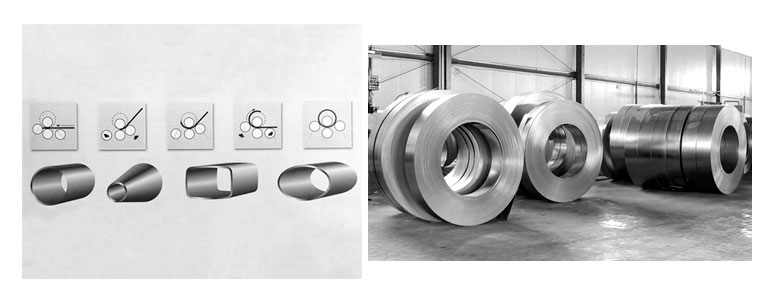

The three-roller and four-roller have different roller motion forms. But their working principles are the same, they all use the principle of three-point fixed circle to roll different radi.

The upper roller is symmetrically positioned at the center of the two lower rollers through the hydraulic oil in the hydraulic cylinder to act on the piston for vertical lifting movement.

The final gear of the reducer drives the gears of the two lower rollers to mesh and rotate to provide torque for the rolled plate.

The four-roller plate rolling machine is suitable for the bending and forming of metal sheets. It can roll round, arc and tapered work pieces within a certain range, and has the function of pre-bending the end of the sheet. The remaining straight edges are small and the work efficiency is high. And the metal sheet can be roughly leveled on this machine.

3-roll asymmetric plate bending machine, the upper roller is the main drive, the lower roller moves vertically to clamp the plate, and the lower roller gear meshes with the upper roller gear, and serves as the main drive at the same time; the side roller makes tilting and lifting movements , With dual functions of pre-bending and rolling. Compact structure, convenient operation and maintenance.

The upper roller of the 4-roller bending machine is the main drive, which is connected with the upper roller through the reducer and cross slider coupling to provide torque for the rolled plate.

The lower roller performs vertical lifting movement, and is provided by the reducer worm gear (bevel gear). The nut and screw are obtained for clamping the plate and are mechanically driven.

There are side rollers on both sides of the lower roller and they are tilted along the rack rails. And they are driven by the nut and worm gear (or bevel gear) ; All four work rolls adopt rolling bearings.

When the 4 roll bending machine is working, the position of the upper roller is fixed, and the lower roller moves upward linearly to clamp the steel plate. The rollers on both sides move in a straight line or arc to move closer to the roller to adjust the radius of curvature of the roll.

Although, four-roller and three-roller bending machine motion forms are different, the working principle is the same. They both use the principle of three-point circle to carry out different radii. However, the pre-bending straight edge and roundness of the 4 roll bending machine are better than those of the three-roller.