Summary:

What kind of crowd is the front-feeding guillotine shear suitable for? What's the use? Why do users need to choose plate shearing machine with feeding table? We will answer and analyze for you one by one.

The front feeding plate shearing machine is especially suitable for the processing of large-scale plate, automatic plant needs high-efficiency, and users hopes to reduce labor and seek convenience.

For workers, it is time-consuming and laborious to carry, load and unload the plates. In particular, large plates need more workers to assist in processing.

The front feeding table is very practical for the processing of long plates. When the long plate sheared, several workers are needed to support and cooperate with the processing.

If the front feed guillotine shear is used, the worker can put the sheet on the feeding table. This saves both effort and labor.

The use of pre-feed device can bring convenience to the vast number of users. Save unnecessary wasted time to do more important things.

Therefore, the front-feeding shearing machine is very suitable for labor-expensive and industrially developed countries and regions. If your factory is short of labor, an automatic CNC shear with feeding table is the good choice!

The CNC front feeding shearing machine is a special product of sheet metal automatic production. The automatic plate shearing machine with feeding table can also connect with other automation equipment such as intelligent warehouse to form flexible production lines.

SHENCHONG high precision shearing machine with front feeding platform can be used to serve for laser welding industry. For automation factory to achieve convenient operation, CNC front-feeding guillotine shear machine for sale is the best choice!

Click here to learn:

Introduction Of Front Feeding Guillotine Shear Explained

High precision and high efficiency

– Cutting linear accuracy: ±0.03mm

– Back gauge speed: 300mm/s

– Back gauge repeat positioning accuracy: ±0.02mm

– Back gauge optional positioning accuracy: ±0.05mm

Advanced Europe technology

CNC hydraulic front feeding guillotine shear is a new generation plate shearing machine with advanced Europe technology. It adopts European style machine design: novel and unique, beautiful and generous.

High-end hydraulic system

It has overload & overflow safety protection, and clear and intuitive display of oil level height.

The front feeding shear can work continuously for 16 hours under rated load. Ensure no leakage, and the processing is stable and high precision.

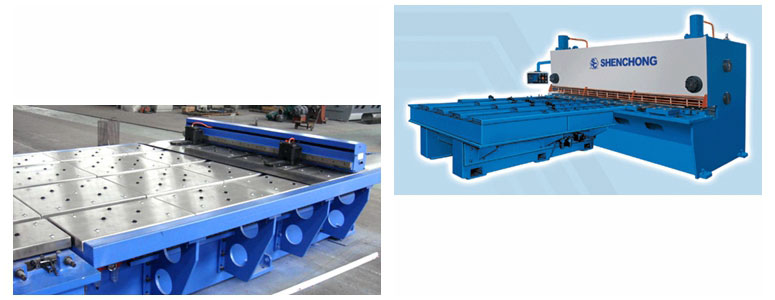

Front Feeding Hydraulic Guillotine Shear Machine

Front-feeding Device

– Front feeding positioning accuracy 0.1mm

– Repeat positioning accuracy 0.06mm

The steel structure of front-feeding device is tempered to eliminates stress with good rigidity and stability.

The feeding system is driven by imported precision ball screw, linear guide and digital AC servo motor. Its positioning is accurate, and the operation is fast and stable.

On the front feeding table, steel balls and brushes are arranged alternately to reduce resistance during feeding. At the same tine, it avoids work piece form scratching on the table surface.

With the function of automatic retreat, the feeding frame can move away in time during the cutting process. In the process of cutting plate, avoid the friction between blade and sheet metal.

DAC360/310 control system

The CNC control system adopts Delem DAC360/310 high brightness LCD display from Holland. Realize the adjustment of cutting angle, blade clearance and shearing stroke.

The user directly inputs the parameters of the cut sheet, and the system controls the two-axis automatic positioning. The system can store 25 working procedures, which can be called up and executed automatically. Easy to operate.

The motor positioning speed of three-axis numerical control can be adjusted arbitrarily to improve the work efficiency.

Built in parameter adjustment function: the reference points of two axes can be modified arbitrarily to adjust the positioning value of CNC system.

Each time the machine is restarted after power failure, the two axes controlled by the CNC system can automatically find the reference point to ensure the repeated positioning accuracy.