The moving upper blade and the fixed lower blade of the high precision shearing machine adopt the reasonable blade gap, the plate shearing machine apply the shearing force to different thickness metal sheets, cut the sheets according to the required size at the high precison.

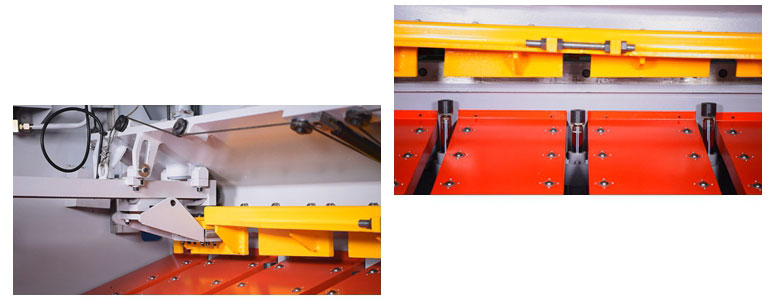

The upper blade of the shearing machine is fixed on the knife body, and the lower blade is fixed on the work table. There are rolling balls installed on the work table, which prevent the sheet being scratched when inserting the sheet into the shearing machine. The shearing machine back gauge is used for positioning the plate, the distance usually controlled by CNC system. The guardrail is safety device to prevent industrial accidents.

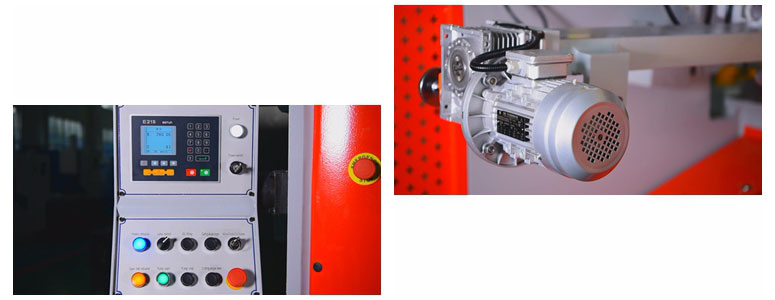

The CNC high-precision shear machine can control machine back gauge, shear angle, blade gap, stroke and pressure. Workers only need input plate thickness, cutting plate width, and choose the correct material, can greatly reduce the burden of skilled workers, reduce work intensity, and improve work efficiency.

Wuxi Shenchong has been dedicated to the production of high-precison shearing machine for more than 20 years. Shenchong CNC high-precision shear machine precision can reach about 0.03mm, which can be used for precision processing.

– Cutting linear accuracy: ±0.03mm

– Back gauge repeat positioning accuracy: ±0.02mm

– Back gauge arbitrary positioning accuracy: ±0.05mm

– Parallel accuracy of back gauge and blade :±0.05mm

The frame is welded construction with steel plate, vibration to eliminate stress, with sufficient rigidity and high strength, steady & reliable performance, easy operation and maintenance.

Completely professional streamlined design, Monoblock by welding robots and apparatus and stress relief process by Annealing treatment.

Adopt integrated hydraulic system, more reliable and easy for maintenance and the hydraulic system from professional company.

Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode.

Closed loop control system is CNC controller, CNC controller has the automatic function of inspection and compensation. The backgauge is driven by servo motor, the positioning precision of the back gauge always keeps high.

Safe fence and the electric inter locker have been designed for the high precision shears to ensure the operation safety to CE regulation.

The positioning accuracy and reliability of the backgauge directly affect the precison of the high-precision shears. Generally, the positioning accuracy of the back gauge of the CNC shear machine can reach ±0.1mm. The parallelism between the backgauge and the lower blade is generally less than 0.20mm in the length of 1000mm, so the accuracy of the machine itself can generally meet the cutting requirements.

In the shearing process, the backgauge needs to withstand the unavoidable impact during positioning, especially for large plates and thick plates. During production, it is necessary to frequently check the deformation of the back gauge, and whether the back gauge is working properly, to ensure its parallelism with the blade and the accuracy of adjustment.

Sheet cutting positioning methods mainly have back gauge cutting and alignment cutting. Alignment cutting includes marking on the plates and then cutting with the light shadow of the shearing machine, cutting the plate with the line on the workbench, and cuting the plate with the tape measure. Because alignment cutting needs to be visually inspected, the precision is obviously worse than the back gauge cutting.

In production, special-shaped parts, large parts and tailings in the cutting process generally need to be alignment cutting. Especially for heavy plate and large parts, due to the heavy weight, it is difficult to fine-tune the positioning when alignment cutting, and the accuracy is even worse.

For sheet cutting, it is difficult to avoid defects and deformations on the edges and sections, mainly including the slope of the section, the raised platform of the section, and the deformation of the shearing edge of the work piece.

At the end of the sheet cutting, the end section of the workpiece will be obviously inclined due to the tearing caused by gravity, and the section of the workpiece on the corresponding table will also be deformed, but it will be smaller. This inclination is generally distributed in the range of 0mm to 150mm at the end of the shear, and the verticality of the section is generally 1mm to 2.5mm.

Therefore, when measuring the workpiece size, you should pay attention to observe and analyze the influence of the inclination of the section, avoid the protruding part, the two ends of the plate, and the excessive burrs, etc., and measure two or three positions to correctly reflect the size of the accessory.

The high precision shearing machine should be able to ensure the cutting sheet metal straightness and parallelism, and minimize the sheet distortion. With the development of science and technology, the product processing accuracy requirements is increasing day by day. CNC high-precision hydraulic shearing machine for sale have gradually become popular. Now more and more customers choose high precision shears.