Hydraulic shearing machine working principle is very simple. The hydraulic guillotine shearing machine, commonly known as "shearing machine", is a sheet cutting equipment and a common equipment for preparing materials. Its purpose is to cut the sheet into long blanks of the required width for processing.

According to the shear properties, it can be divided into flat blade shears and material blade shears. The oblique blade working board machine was used on site. The motor rotates and drives the transmission shaft to rotate through the reduction gear I of the pulley. After the gear reduction is equipped with Z and the semicircular key clutch, the eccentric shaft is driven to rotate, and the rotary motion is changed to the reciprocating movement of the slider along the guide rail through the crank connecting rod mechanism, which drives the blade mounted on the slider to move up and down.

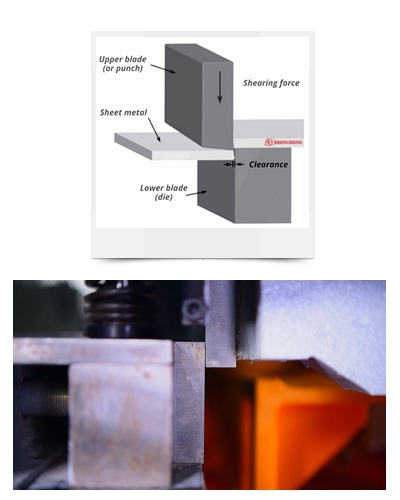

Movement, so as to carry out the shearing work, the use of material blades can reduce the shearing cutting force to facilitate the shearing of longer sheets, but the cut blanks will produce a small amount of bending deformation. When the upper cavity of the oil cylinder at the left end of the machine enters the oil, the piston descends, and at the same time the oil from the lower cavity enters the upper cavity of the oil cylinder at the right end to lower the piston, thereby ensuring the parallel movement of the tool post. When the amount of oil in the tandem oil circuit increases or decreases, the shear angle of the tool post can be changed. When shearing thin plates, the shear angle is reduced to ensure that the sheet material is not distorted; and the stroke amount of the tool post can be shortened, and the number of strokes per minute can be increased.

This structure often uses a nitrogen accumulator to push the return cylinder to shorten the return time, with high speed and small impact, thereby increasing the productivity of the machine. The upper blade of guillotine hydraulic shearing machine is fixed on the knife holder, and the lower blade is fixed on the workbench. A material holding ball is installed on the workbench so that the sheet material will not be scratched when sliding on it. The back gauge is used for positioning the plate, and the position is adjusted by the motor. The pressing cylinder is used to compress the sheet to prevent the sheet from moving during shearing. The guardrail is a safety device to prevent work-related accidents.

1) Start the plate shearer, and the machine runs idly for several cycles to ensure that under normal conditions, the plates with different thicknesses can be sheared from thin to thick. Ensure that users are familiar with the performance of the shears.

2) Different blade clearance must be adjusted for different plate thickness in shear test. If the blade gap is not adjusted, the blade durability will be affected.

3) Turn on the switch of the pressure gauge in the shearing process of the plate shearer, observe the pressure value of the oil circuit, and the pressure should be less than 20MPa when shearing 12mm plate. The remote pressure regulating valve No9 is set at 20-22mpa when it leaves the factory. The user must abide by this regulation. It is not allowed to increase the pressure for cutting the material surface beyond the specification, which will cause damage to the machine. Sound balance during operation.

4) If there is noise in the hydraulic shearing machine, stop the machine for inspection.

5) When the temperature of the oil tank is less than 60 ℃ during the operation of the shearing machine, the machine will be shut down for rest when the temperature exceeds 60 ℃.

The guillotine hydraulic shearing machine is simple to use and easy to learn. They are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide the required special machinery and complete sets of equipment.