Currently, the manufacturing industry is undergoing a transition from human-assisted operations to full automation, giving rise to terms such as "industrial automation" and "smart factory."

Moreover, some modern large-scale manufacturing is done automatically, with little or no human assistance. In order to meet the needs of modernization, industrial automation is undoubtedly an inevitable trend.

Whether it is "Industry 4.0", "Industry 5.0", or the emerging diversified economic market, etc. These not only add to the growing attention but are the main factors driving industrial automation. The continuous increase of this market can be attributed to the continuous development of technical support.

The key technologies in modern manufacturing are industrial Internet of Things, robotics, artificial intelligence, big data, cloud, cybersecurity, new materials and material manufacturing, as well as modeling, simulation, visualization and immersion.

Manufacturing plants supported by these technologies have the advantages of high productivity, accuracy, safety, high quality, intelligence, repeatability, etc. Automated factories such as some manufacturing industries use smart machines to perform the manufacturing process, with minimal human involvement to complete tasks that meet the requirements of product durability, speed and precision.

The Industrial Internet of Things is the continuous integration of various acquisition and control sensors or controllers with sensing and monitoring capabilities, as well as mobile communication, intelligent analysis and other technologies into all aspects of the industrial production process. In this way, the manufacturing efficiency is greatly improved, the product quality is promoted, the product cost and resource consumption are reduced, and finally the traditional industry is upgraded to a new stage of intelligence.

In terms of application form, the application of the Industrial Internet of Things has the characteristics of real-time, automation, embedded (software), security, and information interoperability.

The Industrial Internet of Things utilizes relevant information via tablets, smartphones and other devices to accomplish basic tasks.

For example, enterprises can change their business to a more simplified and adaptive way through data analysis to achieve long-term or short-term goals. Because of this super connectivity, all departments can speed up response and improve the agility of various operations.

Intelligent devices not only perform well in capturing and analyzing data in real time, but also have more accuracy and timeliness in important information to promote business decisions.

Therefore, industrial Internet plays a great role in quality control, traceability, sustainability, overall supply chain efficiency, predictive maintenance, asset tracking, improving on-site service, enhancing customer satisfaction and facility management.

Robots are mechanical devices that perform work automatically. It can accept human commands, run pre-programmed programs, and act according to principles and programs formulated with artificial intelligence technology. Its mission is to assist or replace human work, such as production, handling, stacking, or some dangerous work.

Our concept of robot has gradually come to agreement. Generally speaking, people can accept that a robot is a machine that realizes various functions by its own power and control ability.

The United Nations Organization for standardization adopted the definition of robot given by the American robotics Association: "A programmable and multifunctional operating device; or a specialized system with computer-changeable and programmable actions for performing different tasks." It can bring many conveniences to mankind!

As more and more physical factories become more intelligent and efficient, robots will occupy a more important position in the manufacturing industry. And with the progress of robot technology, these machines can show more complex and excellent functions, including machine learning and memory, higher flexibility and more effective cooperation ability.

Robot has been regarded as an important part of manufacturing. The existence of robot has brought unimaginable advantages.

Artificial Intelligence, referred to as AI, is a new technical science that studies and develops the theories, methods, technologies and application systems used to simulate, extend and expand human intelligence.

Artificial intelligence is a branch of computer science. It attempts to understand the essence of intelligence and produce a new intelligent machine that can respond in a similar way to human intelligence. The research in this field includes robot, language recognition, image recognition, natural language processing and expert system.

Since the birth of artificial intelligence, the theory and technology have become more and more mature, and the application field has been expanding. It is conceivable that the scientific and technological products brought by artificial intelligence will be the "container" of human wisdom in the future.

Artificial intelligence can simulate the information process of human consciousness and thinking. Artificial intelligence is not human intelligence, but it can think like people and may exceed human intelligence.

Artificial intelligence technology has appeared in our daily life in the form of driverless and industrial robots. Technology in manufacturing applications may become a new standard for analyzing large amounts of data and predictive maintenance.

Artificial intelligence will have a huge impact on manufacturing and automation. For example, AI algorithms can be used to optimize the manufacturing supply chain to help companies predict market changes. Market demand can be estimated by linking location search, weather patterns, consumer behavior, political status, socio-economic and macroeconomic factors.

Research institutions have given such a definition: "big data" requires a new processing mode to have stronger decision-making power, insight and discovery power and process optimization ability to adapt to massive, high growth rate and diversified information assets.

Big data requires special technologies to effectively handle a large amount of data over time. Technologies suitable for big data, including large-scale parallel processing database, data mining, distributed file system, distributed database, cloud computing platform, Internet and scalable storage system.

As far as the types and depth of products are concerned, manufacturing is the most complex industry. Enterprises that use big data in manufacturing can meet global development challenges. For example, build smart factories and use MES system for digital and unmanned management.

The way we store and capture data is changing every day, so there are new standards for sharing, transmission, update, search, visual query and information privacy. Manufacturing enterprises need to adopt more powerful technology to keep up with the pace of data update. Therefore, the emergence of enterprise resource planning (ERP) plays a vital role in the business development of enterprises.

Cloud technology is the general name of network technology, information technology, integration technology, management platform technology and application technology based on cloud computing business model application. It can form a resource pool, which can be used on demand and is flexible and convenient.

Cloud technology is an emerging technology. Since it is not maintained locally, nor can it be stored, monitored or protected using traditional methods, but it allows more effective real-time collaboration with it remotely, cloud-based technology may become the main way companies operate in the future.

Compared with traditional data systems, the advantage of cloud technology is that cloud computing is faster, reduces maintenance and improves manageability.

As more and more enterprises turn to cloud based solutions and rely more and more heavily on robot labor, maintaining the integrity and security of the system will become a bigger problem.

As more and more manufacturing enterprises build and integrate their systems through the industrial Internet of things at the same time, there will be more vulnerabilities of information security threats.

Manufacturing enterprises are the backbone of continuously promoting the construction of automation process. Therefore, in the increasingly insecure digital environment, they urgently need to improve security.

To address these vulnerabilities, manufacturing and other industries are paying close attention to cloud based ERP systems. And over time, enterprises of all sizes will rely on cloud based ERP systems. Perhaps in the future, cloud based security is one of the important functions of modern ERP system. However, dealing with the security problem of cloud based ERP is a challenging and complex process.

Additive manufacturing is known by the more generic name of “3D printing”. This is an emerging advanced manufacturing technology. 3D printing can now build large and complex structures in less than a day, a process that used to take weeks to complete.

Using new special consumables is the main development direction of additive manufacturing. This technology is easier for metals, but relatively difficult for high-strength alloys, ceramics and nano ceramics.

Nowadays, additive manufacturing has the potential to provide manufacturing enterprises with new complex design and production capacity, enabling manufacturers to produce customized products and deliver products faster.

When discussing the development of any manufacturing enterprise, it is very important to manipulate, analyze and use data. Enterprises can use new technologies to more effectively display and predict scenarios through new forms of modeling, simulation, visualization and interactive immersion.

Some innovative technologies such as modeling, immersive tools and visualization can be used in many enterprises that rely on big data, including science, manufacturing, healthcare, energy and finance. These innovative displays are not only data, but also an effective way to help the team develop technology and improve the success rate of tasks.

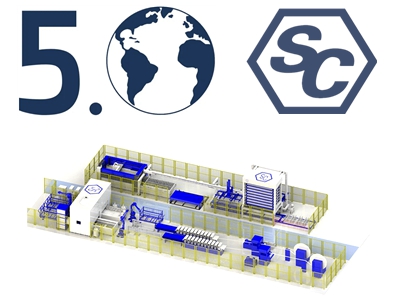

With industry 4.0, we have reached the next milestone in a revolutionary industry. The industry connects the emerging technology with the established trend of manufacturing automation and data exchange, and is committed to bringing the network system into the mainstream and placing it at the forefront of the manufacturing industry. Therefore, this is also known as the "fourth industrial revolution".

And with modern conceptualized and realized technologies, industry 5.0 has emerged. With the support of intelligent devices and the continuous improvement of data processing and access capabilities, our factory will become more productive, efficient and energy-saving, and finally enter a new era!