Stainless steel materials have many advantages such as wear resistance, anti-corrosion and acid resistance. Surface smooth and easy to clean, usually will not rust and deform, etc. Therefore, now stainless steel has become the preferred material for kitchenware. It can be said that most of the kitchenware is made of stainless steel.

The kitchen cabinets and workbenches choose stainless steel because stainless steel is environmentally friendly, no need to worry about radiation. And stainless steel workbenches are not easy to breed bacteria.

In the kitchenware, stainless steel can be made into an integrated shape with the basin and baffle, without gaps, and stainless steel has good reverse osmosis. If the kitchen workbench is sprinkled with oil or water stains, we only need to use a rag to gently clean it.

Now most of the stainless steel kitchenware are made of 304 stainless steel, which is durable, corrosion-resistant, high-temperature resistant, moisture-proof, impermeable, etc., and can be safely used in food contact.

From the stainless steel kitchenware processing technology analysis, according to the properties of stainless steel, it refers to the process of cutting, bending, bending, welding and other mechanical processing. We finally obtaine the stainless steel products required for industrial production.

In the process of stainless steel processing, we need a large number of machine tools, instruments, and stainless steel processing equipment. Stainless steel processing equipments are classified into cutting equipment, bending equipment and surface treatment equipment. Cutting equipments are further divided into cut to length machine line and slitting machine line.

In addition, from the thickness of stainless steel, which can also be divided into hot and cold rolling processing equipment. Thermal cutting equipment mainly includes plasma cutting, laser cutting, water cutting and so on.

Original surface: surface subjected to heat treatment and pickling treatment after hot rolling. Generally used for cold-rolled materials, industrial tanks, chemical industrial equipment, etc., the thickness is thicker from 2.0MM to 8.0MM.

Blunt surface: after heat treatment and pickling after cold rolling, the material is soft and the surface is silvery white, used for deep drawing processing, such as automobile components, water pipes, etc.

Matte surface: After cold rolling, it is heat treated, pickled, and then finished rolling to make the surface moderately bright. Due to the smooth surface, it is easy to regrind to make the surface brighter, which will have a wide range of uses, such as tableware, building materials, etc. With a surface treatment to improve mechanical properties, it is almost suitable for all purposes.

Coarse sand, stainless steel product that is ground by grinding belt NO.100-120. Has better gloss, with discontinuous coarse grain. Used for building interior and exterior decoration materials, electrical products and kitchen equipment, etc.

Fine sand: stainless steel product that is ground by grinding belt NO. 150-180. It has better glossiness, has discontinuous coarse grains, and the stripes are thinner. Which can be used in bathrooms, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment, etc.

#320, stainless steel product ground by No. 320 grinding belt. It has better glossiness, has discontinuous coarse grains, and the stripes are thinner than Fine sand. The products are used in bathrooms, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment, etc.

Hairline surface: Stainless steel product by continuous grinding with a polishing abrasive belt of appropriate particle size (subdivision No. 150-320). It is mainly used for architectural decoration, elevators, doors and panels of buildings, etc.

Bright side: BA is cold-rolled, bright annealed, and smoothed. The surface gloss is excellent and has high reflectivity. Like a mirror surface. Which can be used in home appliances, mirrors, kitchen equipment, decorative materials, etc.

Related articles about stainless steel finishes:

Stainless Steel Surface Treatment And Processing Technology

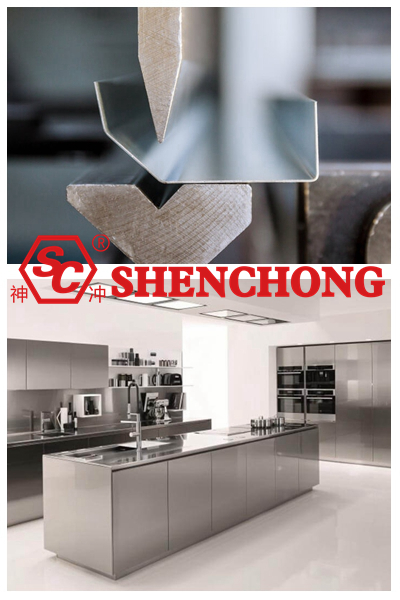

Stainless steel kitchen cabinet production equipment refers to the equipment used to produce different stainless steel kitchenware, usually include cutting, bending, welding, polishing, manufacturing and other production process. These equipment can produce high-quality, environmentally friendly, safe and hygienic stainless steel kitchenware to meet people's needs

First of all, stainless steel cabinet production equipment includes cutting machine. Cutting is the first step in the processing of stainless steel. Usually we can choose CNC laser cutting machine or hydraulic shearing machine. The cutting machine can be set to cut according to different requirements, such as automatic cutting according to graphics, or cutting according to different sheet materials, or different accuracy requirements.

Secondly, The press brake machine is an indispensable machine in the stainless steel cabinet production equipment. The press brake machine can bend the sheet metal to be different angles. Equipped with different tools, press brake machine can bend sheet metal to be different shapes; Equipped with suitable tools, press brake machine can also be used for punching, stretching, etc. High precision CNC hydraulic press brake machine determines the stainless steel work piece precision and quality. The CNC hydraulic press brake machine of Wuxi Shenchong Forging Machine Co.,Ltd, models WEK and WDK all have the characteristics of high precision, simple operation and good mute effect.

Thirdly, welding equipment is also a key tool in stainless steel kitchenware production equipment. Welding technology is one of the most important links in the production of stainless steel kitchen work piece, which determines the quality and service life of stainless steel kitchenware. Therefore, welding equipment needs to have the characteristics of high precision, good weld quality, and strong stability.

Fourthly, polishing equipment is also very important. When manufacturing stainless steel kitchenware, the glossiness of the surface is very important, it will directly affect the appearance and quality of the stainless steel kitchenware. Polishing equipment can complete the surface polishing of stainless steel in a short time, making the surface of the product smooth and bright.

Finally, manufacturing equipment is the most important step in the final shaping of stainless steel kitchenware. When manufacturing stainless steel kitchenware, every detail needs to be carefully designed and manufactured, such as handles, handles and lids. The manufacturing equipment can manufacture high-quality stainless steel cabinet products according to the design requirements. It has stable performance and high production efficiency, which can meet the needs of customers.