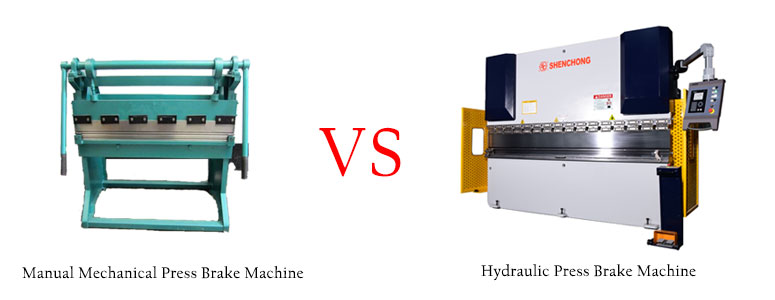

Press brake machine on sale currently mainly have manual mechanical type and hydraulic type on the market. And widely used in light industry, shipbuilding, electrical appliances, stainless steel products, and decoration industries.

Why hydraulic press brake is hot sale now? Which type is the best and most popular?

With the development of hydraulic technology, considering the shortcomings of mechanical press brake, hydraulic press brake machines are becoming more and more popular.

Mechanical bending machines are being phased out, while hydraulic press brakes are hot sale. Why? Let’s analyze their differences and characteristics.

Introduce:

The structure of the manual bending machine is relatively simple. It is more laborious to operate manually, which is suitable for small-scale processing. But its price is much lower.

For example: Tennsmith in the United States sells manual 34 Ton press brake.

Disadvantages of mechanical bending machine:

- The stroke and speed cannot be adjusted.

- The effective pressure is only about 60%.

- Mechanical type is difficult to achieve numerical control.

- Poor bending accuracy.

American manufacturers such as tennsmith, betenbender and Cincinnati, which originally produced manual bending machines, also start to sell hydraulic bending machines. Here are a lot of mini hydraulic press brake machine for sale on craigslist.

Introduce

With people’s requirements for process accuracy and efficiency, hydraulic bending machines have gradually replaced mechanical bending machines.

– According to the synchronization mode,hydraulic press brakes are divided into torsion shaft synchronization and electrical hydraulic synchronization press brake.

– According to the movement mode, it can be divided into an upper movement type and a lower movement type.

Advantages of hydraulic press brake

- Have a larger working schedule

- The speed is faster, there are slow and fast

- Double oil cylinder synchronization, greatly improving the bending accuracy

- The maximum pressure can be reached at any point

- Can realize CNC

- Hydraulic press brake machine price reasonable

We can divide hydraulic press brake machine into torsion shaft type and electrical hydraulic type. Which one is better?

The electrical hydraulic type is a CNC press brake machine. Torsion shaft hydraulic press brake machine is almost NC control.

Compared with ordinary NC hydraulic press brake machine, CNC hydraulic press brake has more advantages.

More advanced hydraulic press brake machine design

Higher accuracy and efficiency

Faster and convenient

Can do partial load bending

Click here to know how to run a hydraulic brake press machine

Hydraulic press brake machine is hot sale in North America like Canada. Youngstown Ohio city in the USA is torsion shaft hydraulic press brake a lot.

In Asia, CNC hydraulic press brake machine in Japan, South Korea, Singapore. And other countries like India, Philippines is second hand hydraulic press brake machine torsion shaft type a lot.

In Africa, like South Africa, mainly used hydraulic press brake machine torsion shaft type as well.

In Europe and Australia, mainly use CNC electrical hydraulic press brake.

If the higher-tonnage hydraulic press brake machine is over 250 Ton, simple hydraulic type can not work well. We suggest you to choose CNC electrical hydraulic type.

Becuase the manufacturing cost of the 300Ton torsion shaft NC hydraulic press brake machine is very high. And it is close to the electro-hydraulic press brake. Therefore, higher-tonnage bending machines are more suitable to be designed as CNC electrical hydraulic press brake.

For detailed tonnage information, you can consult the hydraulic press brake machine manufacturers for hydraulic press brake machine pdf catalog.

In some decoration industries, they have relatively high requirements on the accuracy of products. But the torsion shaft press brake cannot meet it. So they are more willing to choose electrical-hydraulic press brake with high precision.

As industry competition and worker costs increase, efficiency has become a more critical factor. Due to the faster speed of electrical hydraulic press brake, many factories have gradually begun to use CNC electrical hydraulic press brake machine.

However, there are many small companies that intend to improve the accuracy of their products, but without enough capital to buy new electrical hydraulic press brake machines. They will buy used CNC electrical hydraulic press brake.

Used primeline, amada, and trumph CNC hydraulic press brake machines are popular in a lot of developing countries. Used hydraulic press brake machine in India like in Ahmedabad, Kolkata, Delhi, Kerala city is very common.

Taking the Chinese market as an example, as domestic and foreign companies have higher requirements for workpieces, it is gradually moving towards the area of comprehensive CNC electrical hydraulic press brake.

And CNC hydraulic press brake machine have developed from the early 3-axis to 8-axis. SHENCHONG not only manufactured a 16-axis dual-machine linkage bending machine, but also launched a robotic press brake in compliance with international trends. SHENCHONG company will continue to provide the most effective solution for automated bending.