Classification of Plate Cutting Machines

Plate cutting machine is one of the forging machines, mainly used in the metal processing industry. Products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration, and other industries.

Classification of Plate Cutting Machines

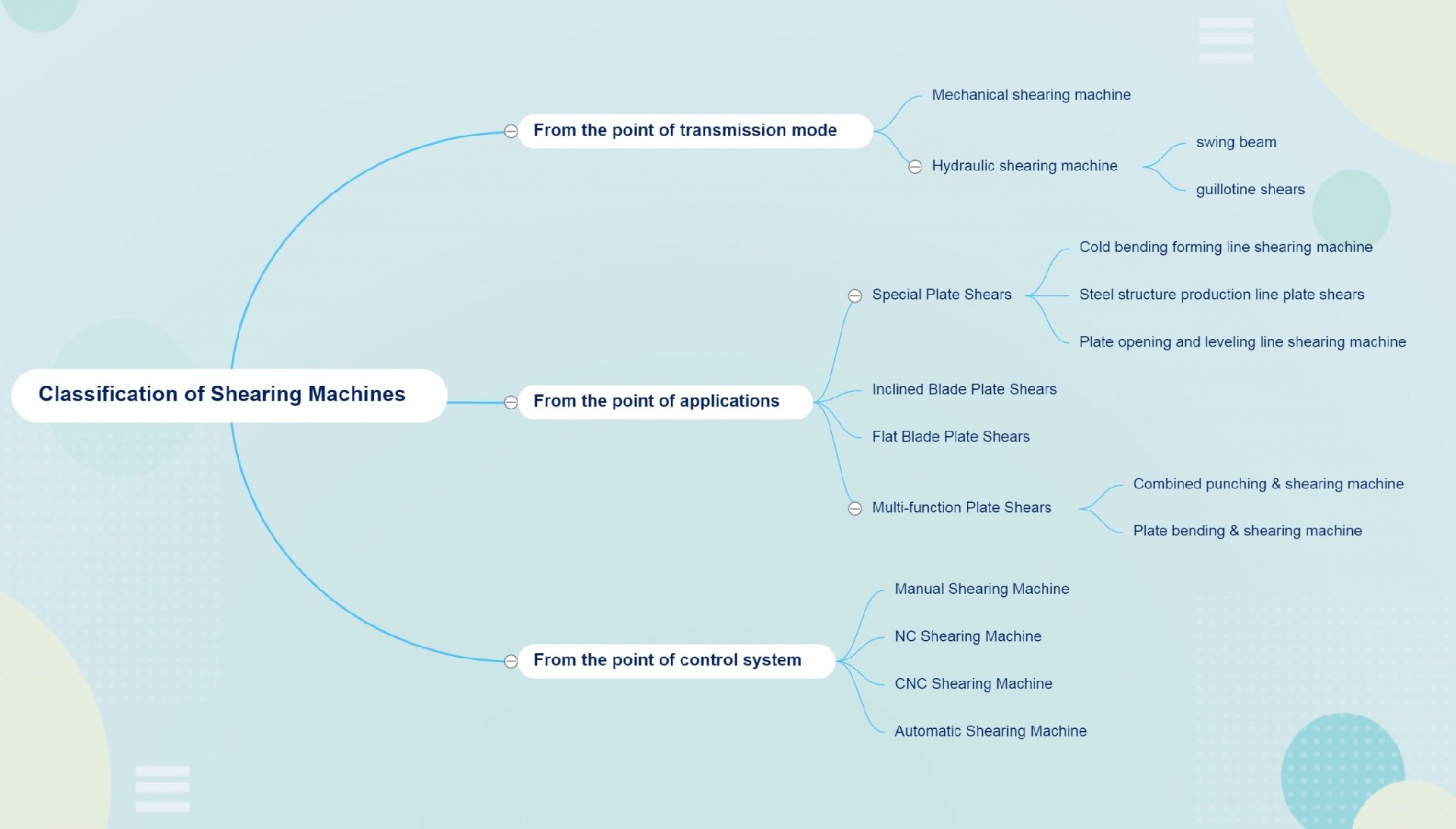

At present, there are many kinds of plate shear machine for sale on the market. We always classify according to the cutting machine working principle and structure.

Before analyzing the classification, you should know more about the principle and structure of plate shears.

Tips: (This part of the passage is not the main body.)

Working Principles:

Sheet metal cutting machine is an equipment that uses one blade to make reciprocating linear motion relative to the other blade to cut plates.

Through moving upper blade and fixed lower blade, it exerts a shear force on metal or steel plates of various thicknesses with reasonable blade clearance. Then, the plates can be shaped or separated according to the required size.

Plate cutting machine parts:

The structure of the shear machine mainly includes:

Transmission system, frame, slide block, tool holder, pressing mechanism, retaining mechanism, balancer, electrical control system, lubrication system, and other auxiliary devices (sealing ring, valve, N2 nitrogen return, etc.).

Drive system:

There are 3 kinds of transmission forms of sheet cutting machines: mechanical transmission, hydraulic transmission, and hydraulic mechanical combined transmission.

The appearance structure and performance function of metal sheet cutting machines are closely related to the transmission mode used.

So metal steel cutting machine is divided into 2 main types according to the transmission system: mechanical shear and hydraulic shear.

Mechanical Cutting Machine VS Hydraulic Plate Cutting Machine

According to the working principle, we can divide cutting machines into the following two categories: Mechanical shear and Hydraulic shear.

- Mechanical cutting machine: up moving type and down driving type.

- Hydraulic plate cutting machine: swing beam shears and guillotine shears.

- The shear thickness is less than 10 mm, it is always a mechanical shear machine. If the thickness is more than 10 mm, it is generally a hydraulic plate cutting machine.

Generally speaking, the old small cutting machines for sale in the past mainly used mechanical transmission. This is more economical and cost-effective. But with the development of technology and production, the hydraulic plate cutting machines have occupied the mainstream market. Now, most of the new plate cutting machines for sale use a hydraulic system.

Mechanical Transmission

The transmission system of the mechanical cutting machine is similar to that of punch. The utility model is composed of a motor, a flywheel, a clutch, a crank connecting rod mechanism, a brake, a shearing slide block, a pressing slide block, etc. The operation performance and danger are similar to that of punch.

Advantages:

- Fast cutting speed

Disadvantages:

- Loud noise and poor safety performance.

- Can’t work at full load for a long time. No overload work. Otherwise, it is easy to damage the machine parts.

- There are too many vulnerable parts such as the clutch part, shaft sleeve, and brake belt.

- The adjustment of blade clearance and the maintenance of machine tools is time-consuming (usually more than half an hour).

- It is not suitable for long plate shears and heavy plate shears.

- Compared with hydraulic cutting machines, the cost is higher.

- Nowadays, it is no longer popular in the worldwide market. But it is still popular in India.

Top Mechanical Cutting Machine Manufacturers

- KESHAV: Kesahv New Tech (India)

- HPSM: HP Singh Machinery Pvt. Ltd. (India)

- SPA SHUBHAM: Shubhampress Automation Private Limited (India)

- Manufacturers and user groups are mainly in underdeveloped regions, such as India.

Hydraulic Transmission

The transmission mechanism that hydraulic cutting machine used is simple. The hydraulic cylinder directly pushes the pressing slide and the shearing slide to work.

It is easy to operate and can realize single stroke, continuous stroke, inching stroke and return stroke. It is safe to work and can prevent equipment accidents caused by overload. Stable operation, small vibration, low noise, can extend the tool life.

But it needs a complex and precise hydraulic control system. The maintenance work is heavy.

Advantages:

- Large shear force and hydraulic overload protection reduce the damage to the machine tool.

- Equipped with electric back gauge and digital display, convenient and fast.

- The gap of the knife-edge adjusted rapidly to save time and labor.

- After the sheet cutting is completed, the upper tool holder automatically picks up. It is not slower than mechanical plate shears.

- Few faults

- The maintenance is convenient and quick.

Disadvantages:

- When full load cut, the speed is slightly slow.

Tips: (This part of the passage is not the main body.)

Comparison of Mechanical Shears VS Hydraulic Plate Cutting Machines

As we all know, the hydraulic plate cutting machine is much better than a mechanical cutting machine.

For example: the technology of large mechanical cutting machine is very complex. The machine is bigger, heavier, and more expensive.

Therefore, the mechanical plate shears are gradually eliminated and fade out of the market. And hydraulic plate shears are the most widely sold and used in the world.

Hydraulic Plate Cutting Machine Classification

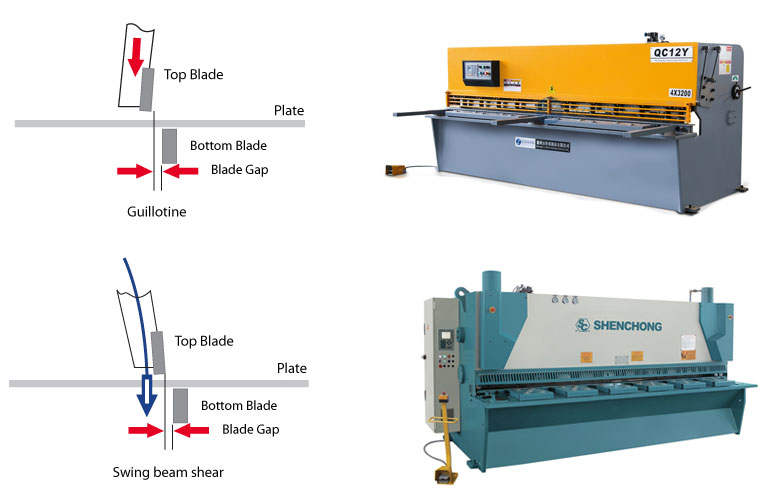

Furthermore, the hydraulic shear machine can be divided into 2 types: Swing beam cutting machine and the guillotine cutting machine. This classification is mainly based on different cutting principles.

Blade holder shearing operation mode:

Principle of single-point support and lever: arc curve motion of later fulcrum.

Cutting blade return device:

Homemade return cylinder. It is easy to leak and needs frequent maintenance.

Scope of use:

Applicable to ordinary small and medium-sized workpieces or products with common requirements of cutting surface.

Advantages:

- Simple structure

- Few accessories

- Better for small machines

- Low price

Disadvantages:

- Use diamond steel cutting blade

- Short blade edge using life

- Poor shearing accuracy

- Poor shear quality

Top Swing Beam Hydraulic Plate Cutting Machine Manufacturers

- Jean Perrot (France)

- Shearchy: WUXI SHEARCHY TECHNOLOGY CO., LTD (China)

- JAYSON: Jayson Machines Impex (India)

- SANTEC: Santec Group (India)

Blade holder shearing operation mode:

Three-point support rolling guide rail (including lower eccentric shaft, front support shaft, upper eccentric shaft): the cutting blade holder moves up and down in a straight line.

Cutting blade return device:

Pneumatic accumulator. Nitrogen return, stable and reliable.

Scope of use:

Suitable for large and medium-sized workpieces and ultra-long plates. Workpiece with high demand for shear plane surface accuracy.

Advantages:

- Long service life of steel cutting blade

- Higher shearing accuracy

- Shear angle adjustable

- Excellent cutting quality

- Can be fully CNC

Disadvantages:

- Relatively high price

Top Hydraulic Guillotine Cutting Machine Manufacturers

- LVD (Belgium)

- SHENCHONG: Wuxi Shenchong Forging Machine Co., Ltd. (China)

- RAJPOWER: RAJESH MACHINES LLP (India)

Tips: (This part of the passage is not the main body.)

Comparison of Swing Beam Shear VS Guillotine Shear

In the early days, the old hydraulic plate cutting machine for sale were swing beam type. With the continuous development of science and technology, CNC hydraulic guillotine shear has come out and become more and more popular.

Compared with the cheap swing beam pneumatic plate cutter machine, the hydraulic guillotine cutting machine has more advantages in performance and use. For example, in terms of accuracy, speed, operation, etc.

Special plate cuting machines are mostly used with other equipment to complete special purposes.

Cold bending forming line plate cutting machine:

Such as the plate shears configured on the production line of automobile longitudinal beam, side baffle of carriage, color steel plate, etc.

Steel structure production line plate shears:

Mostly used in angle steel, H-beam automatic production line to complete the cutting process.

Plate opening and leveling line palte cutting machine:

Lever cutting machine is used for plate opening and leveling line. High-speed cutting machine designed to meet the requirements of high-speed cutting in the production line.

- For thick plates, hydraulic high-speed plate shears are mostly used.

- For thin plates, pneumatic cutting machines are mostly used.

- High-speed lines will be equipped with flying cutting machines: continuous production, high efficiency.

The upper and lower blades of the plate cutting machine form an angle. Generally, the upper blade is inclined, and its inclination angle is generally 1 ° to 6 °.

The shear force of the inclined blade cutting machine is smaller than that of the flat blade shears. Therefore, the motor power and the whole machine weight are greatly reduced.

Its practical application is the most. Now, most plate cutting machine manufacturers produce this type of shear.

Its shear quality is good and distortion is small. But the shear force is large and the energy consumption is large.

The upper and lower blades are parallel to each other, and most of these shears are mechanical plate cutting machine. It is commonly used in hot shear bloom and slab in the rolling mill.

According to the shear mode, it can be divided into upper drive type and lower drive type.

Combined punching and cutting machines can not only cut the plate, but also cut the profile.

Two processes of cutting and bending can be completed on the one equipment.

In the past, we used the old-fashioned hand plate cut machine. Nowadays, in some industrial and economic backward areas, many small factories and workshops still use it.

For the simple processing of very some small workpieces in small-batch, the manual plate cutting machine can complete. However, it is very time-consuming, laborious and dangerous.

NC plate cuting machine is equipped with digital display, which is the low configuration of a numerical control cutting machine.

CNC plate cutting machine adopts a CNC control system. The accumulator returns more smoothly and quickly. CNC controls the length, width, thickness, and angle of cutting.

Difference between digital display and numerical control

Digital Display:

Reach preset value after preset. But only one value can be set at a time.

Numerical Control:

Preset multiple values to achieve the preset effect. More adjustable and flexible.

- Shear machine frequency conversion numerical control: common motor plus frequency converter. Adjustable speed.

- Shear machine servo CNC: servo motor. Can alarm.

Top CNC Plate Cutting Machine Manufacturers

- LVD (Belgium)

- SHENCHONG: Wuxi Shenchong Forging Machine Co., Ltd. (China)

- DKD: DKD IKJOT UNITED (New York, USA)

- JMT: DBA of Jorgenson Machine Tools, Inc. (USA)

- Shailesh: Shailesh Machine Tools (India)

The automatic cutting machine is a more high-end CNC guillotine cutting machine.

Such as, SHENCHONG front-feeding hydraulic guillotine shear with automatic loading & unloading device and platform. It is a good choice for automated production lines require fast and easy operation.